Choosing the right fabric for sports uniforms is critical. It must handle wear and tear, allow free movement, and maintain its shape. This guide explains how tensile strength and stretch tests ensure fabric durability and flexibility. Key points include:

- Tensile Strength: Measures how much force a fabric can withstand before breaking.

- Stretch and Recovery: Evaluates how well a fabric stretches and returns to its original shape.

- Testing Standards: Common methods like ASTM D5034 (breaking strength) and ASTM D4964 (elasticity) ensure reliable results.

Proper preparation, including fabric conditioning and sample cutting, is crucial for accurate testing. Manual stress tests and seam evaluations help identify weak points, while stretch tests ensure the fabric supports athletic movements without deformation. Following these steps ensures you select fabrics that perform well under intense sports conditions.

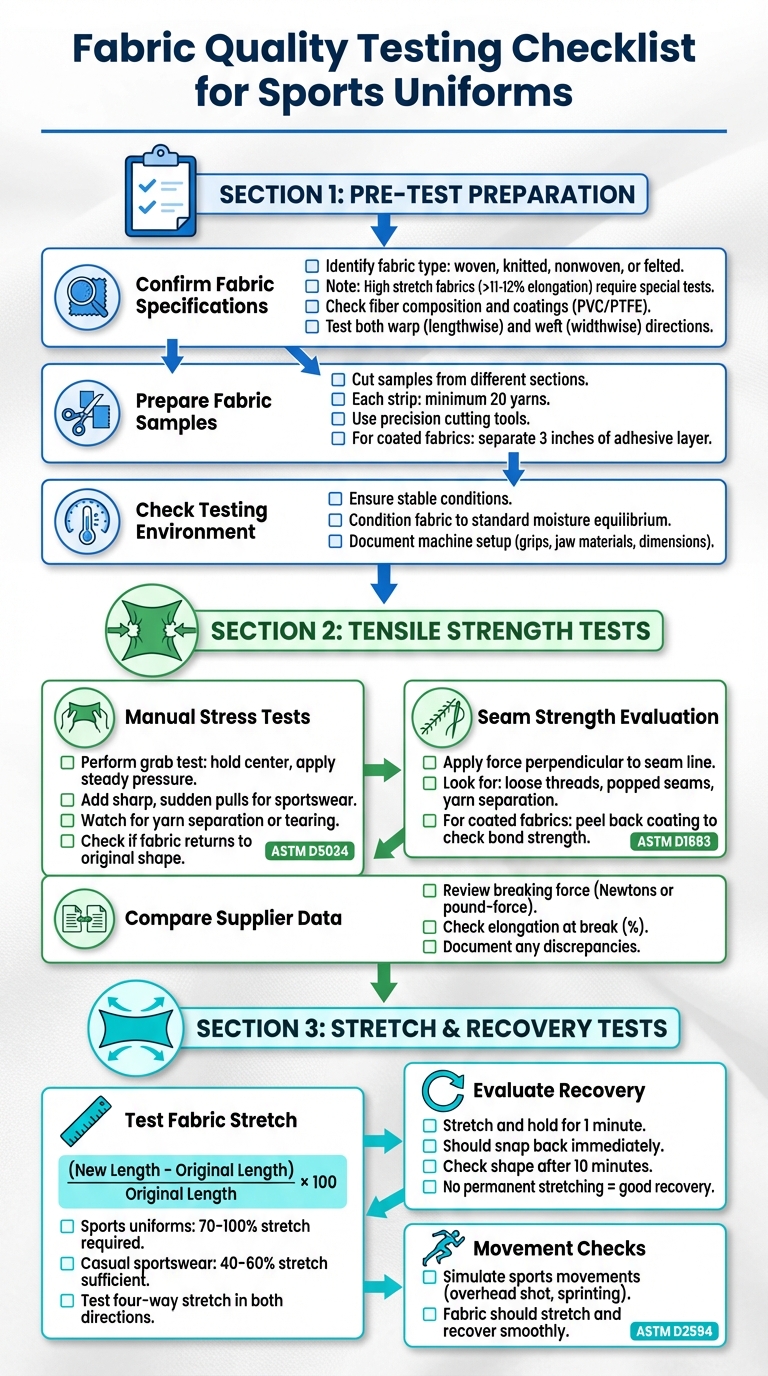

Complete Fabric Quality Testing Checklist for Sports Uniforms

Fabric Tensile Strength Test Process – Grab and Strip Method

sbb-itb-4d95ad3

Pre-Test Preparation Checklist

Getting ready for fabric testing? Proper preparation is key to obtaining accurate and consistent results. Here’s what you need to focus on: fabric specifications, sample preparation, and your testing environment.

Confirm Fabric Specifications

Begin by determining whether your fabric is woven, knitted, nonwoven, or felted, as this will dictate the appropriate test method. For fabrics with high stretch (greater than 11–12% elongation), standard tensile tests like ASTM D5034 aren’t suitable. Take note of the fiber composition and any special treatments, such as PVC or PTFE coatings, which can greatly increase tensile strength. Remember, plain weave patterns are generally stronger than twill due to the higher number of warp and weft intersections. Also, confirm whether testing is required in both the warp direction (lengthwise) and the weft direction (widthwise), as fabric performance often varies between these orientations.

Prepare Fabric Samples

When preparing samples, cut them from different sections and directions of the fabric roll. Each strip sample should include at least 20 yarns; if a 1-inch strip isn’t enough, opt for a 2-inch strip. Use precision cutting tools to ensure the samples have consistent dimensions. For coated fabrics, make sure to separate at least 3 inches of the adhesive layer from the substrate before mounting the sample. Keep in mind that grab tests require less preparation but use more fabric per specimen, while strip tests demand more precise cutting.

Check Testing Environment

Stable environmental conditions are essential for reliable testing. According to ASTM International, "Comparison of results from tensile testing machines operating on different principles is not recommended". Ensure your fabric is properly conditioned to achieve standard moisture equilibrium before testing, or note if you’re testing wet samples. Document all machine setup details, such as grip types, jaw materials, and dimensions, as these can influence the results. For high-stretch materials, consider using a long-travel extensometer to capture precise elongation data.

Tensile Strength Checklist

Once your samples are prepared and the testing environment is set, it’s time to simulate the kinds of stresses the fabric will endure during actual use. These tests will help you evaluate how well the material holds up under demanding conditions.

Manual Stress Tests

Begin with a manual grab test – hold the center of a fabric panel firmly with both hands (acting as the grips of a testing machine) and apply steady, even pressure in opposite directions. Watch for signs like yarn separation or tearing. This method aligns with ASTM D5034 standards. For sportswear, add sharp, sudden pulls to replicate the tugging and high-impact movements typical in competitive scenarios. After each pull, check if the fabric returns to its original shape. If it stays stretched or distorted, that’s a red flag for weak structural integrity. Don’t forget to examine the seams carefully, as they often reveal potential weak spots.

Seam Strength Evaluation

Seams are particularly vulnerable in sports uniforms, so testing their durability is critical. Apply force perpendicular to the seam line and look for issues like loose threads, popped seams, or yarn separation. This process follows ASTM D1683 guidelines. For coated fabrics, peel back the coating gently to inspect the bond strength. Poor adhesion between the coating and the base fabric can drastically weaken seam durability.

Compare Supplier Data with Observations

After completing the manual tests, match your results against the supplier’s technical data sheet. Key metrics to review include breaking force (measured in Newtons or pound-force) and elongation at break (expressed as a percentage). While manual tests won’t provide exact force measurements, they’re still a useful way to confirm if the fabric meets the durability claims listed in the spec sheet. If you notice discrepancies between your findings and the supplier’s data, take note of the testing conditions and document them for further analysis .

Stretch and Recovery Checklist

When creating athletic apparel, testing a fabric’s stretch and recovery is just as critical as verifying its tensile strength. These properties ensure the garment can handle the rigors of sports and maintain its performance.

Test Fabric Stretch Behavior

To measure stretch, take a fabric sample, apply even tension, and calculate the stretch percentage using this formula: (New Length – Original Length) / Original Length × 100. For fabrics with four-way stretch, be sure to test both lengthwise and crosswise directions to confirm consistent performance across all axes. Typically, sports uniforms require a stretch range of 70–100%, while casual sportswear can often suffice with 40–60%. After determining the stretch, check how well the fabric recovers once the tension is released.

Evaluate Recovery After Stretching

To assess recovery, stretch the fabric and hold it for one minute to mimic sustained tension, then release it. The material should snap back to its original size immediately and maintain that shape after 10 minutes. If it shows any permanent stretching, that’s a sign of poor recovery. Differentiating between temporary stretch and permanent elongation is vital to ensure the garment keeps its fit throughout its use.

Movement Checks for Sports

Put the fabric through simulated sports movements, like taking an overhead shot or sprinting. It should stretch and recover smoothly, without creating tension in areas that experience repeated motion. This behavior, referred to as "momentary stress" in ASTM D2594, is a key indicator of the fabric’s suitability for athletic wear.

Conclusion

Key Takeaways

Testing fabric quality is essential to ensure uniforms can handle the demands of competitive sports. It all starts with pre-test preparation, where fabric specifications are confirmed, and a controlled environment is set up for accurate testing. Manual stress tests and seam strength evaluations play a crucial role in determining whether the material can endure high-impact situations without tearing at vital seams.

Equally important is the stretch and recovery phase. Fabrics must allow a full range of motion during play while returning to their original shape afterward. Differentiating between permanent elongation and temporary stretch is critical to avoid deformation. Skipping proper recovery testing could lead to rapid wear and loss of fit, impacting both performance and appearance.

Using standardized testing methods is key to generating reliable data that reflects real-world performance. Tailoring testing methods to the specific fabric type ensures accurate results, helping to avoid misleading conclusions. Ultimately, this thorough approach to testing translates into uniforms that perform reliably on the field.

How Wooter Apparel Supports Teams

At Wooter Apparel, rigorous fabric testing is at the heart of every uniform we create. By following strict testing protocols, we ensure our fabrics consistently perform under game-day conditions. Before any material is used, it undergoes thorough evaluation for tensile strength, elongation, seam integrity, and recovery properties. This ensures they can meet the physical demands of sports like basketball, football, baseball, softball, and soccer.

Our sublimated designs are crafted with fabrics tested for both momentary stress (like a quick jump shot) and prolonged stress (like extended wear during a game). Starting at just $16.99 per item, our custom uniforms are built for durability, flexibility, and comfort. Thanks to our commitment to quality testing, you can trust that your uniforms will hold up when it matters most.

FAQs

What’s the difference between tensile strength and stretch testing in fabrics?

Tensile strength refers to the maximum force a fabric can endure before it breaks, providing a clear picture of its durability and resistance to tearing. On the other hand, stretch testing assesses how much a fabric can stretch under tension and its ability to return to its original shape, highlighting its elasticity and flexibility.

These tests play a crucial role in ensuring fabric quality, particularly for sports uniforms, where both durability and stretch are critical for performance and comfort.

How can I ensure reliable fabric test results in different environments?

To achieve reliable and consistent results during fabric testing, controlling environmental conditions is a must. Begin by conditioning your fabric samples in a standard climate chamber set at 70°F (21°C) and 65% relative humidity for a minimum of 24 hours, as outlined by ASTM standards. Be sure to log the temperature and humidity levels both before and after testing to account for any fluctuations.

Choose the correct ASTM method based on the property you’re evaluating. For stretch properties, refer to ASTM D3107, while tensile strength testing should follow ASTM D5034. Make sure your testing equipment is calibrated correctly and set to the recommended specifications for speed, grip type, and specimen size. To enhance accuracy, perform each test at least three times, varying the sample orientation randomly.

These steps are crucial for evaluating fabric performance, whether you’re in a controlled lab environment or a practical setting. At Wooter Apparel, we adhere to these stringent testing protocols to ensure our custom team uniforms deliver top-notch durability and stretch, meeting the demands of athletes across the United States.

Why is it important to test fabric strength and stretch in both warp and weft directions?

Testing the warp (longitudinal) and weft (transverse) directions of fabric is essential since these two orientations often behave differently in terms of strength and stretch. By assessing both, you can ensure the material can withstand the multidirectional stresses that come with athletic activities, like sharp movements and frequent use.

This kind of detailed testing verifies the fabric’s durability, elasticity, and dependability – key qualities for crafting top-notch sports uniforms built to perform under tough conditions.