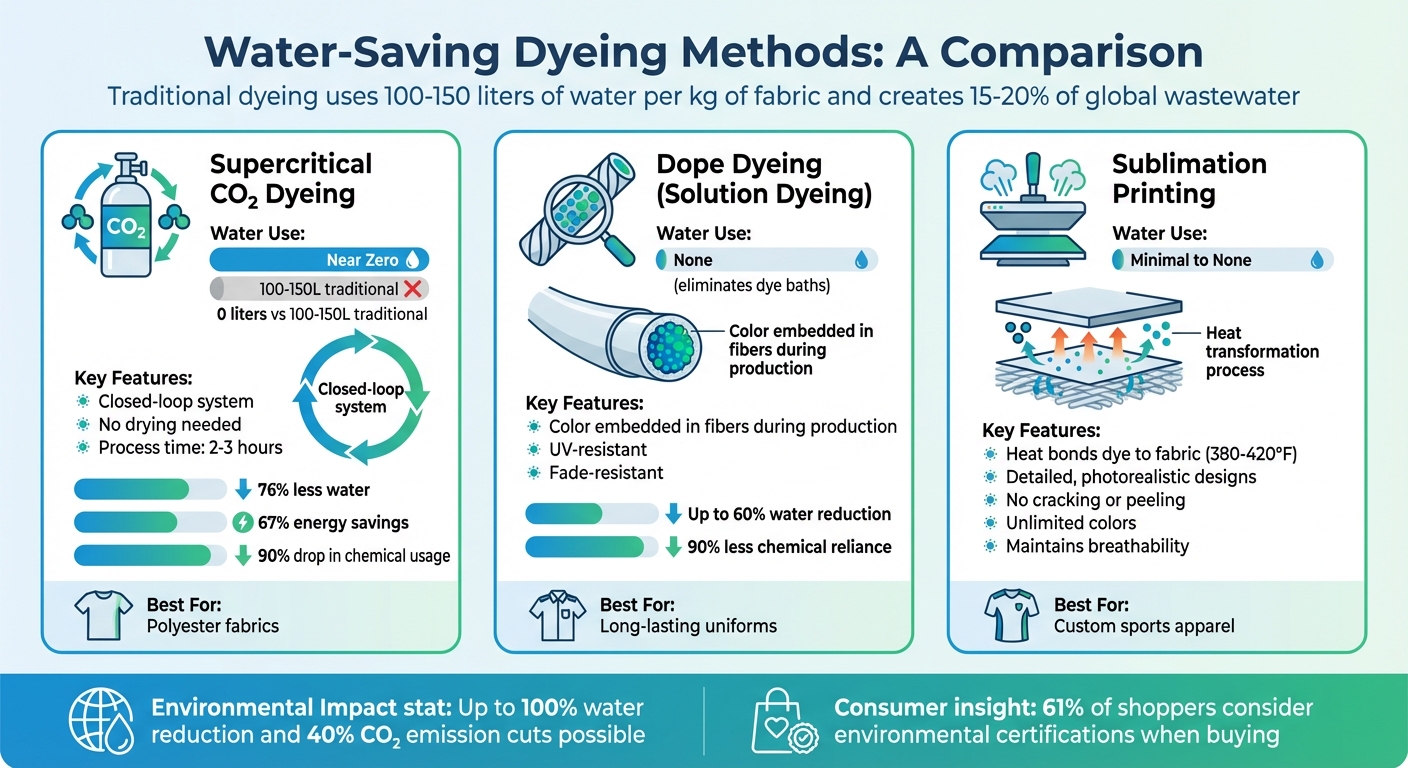

Dyeing fabrics can be a water-intensive process, consuming up to 150 liters of water per kilogram of material and contributing to 15-20% of global wastewater. But new methods are tackling this issue by significantly reducing or eliminating water use while maintaining fabric quality and performance.

Key methods include:

- Supercritical CO₂ Dyeing: Uses pressurized CO₂ instead of water, cutting water use to zero and saving energy with no drying required.

- Dope Dyeing: Adds color directly into fibers during production, eliminating water-heavy dye baths and creating long-lasting, fade-resistant fabrics.

- Sublimation Printing: A waterless process that uses heat to bond dye directly to polyester, ensuring vibrant, durable designs without cracking or peeling.

These techniques are transforming sportswear production by reducing resource use, lowering waste, and delivering durable, high-performance apparel. For example, sublimation printing allows detailed, customizable designs while avoiding water pollution and dye waste.

Quick Comparison:

| Method | Water Use | Key Features | Best For |

|---|---|---|---|

| Supercritical CO₂ Dyeing | Near zero | Closed-loop system, no drying needed | Polyester fabrics |

| Dope Dyeing | None | Color embedded in fibers, UV-resistant | Long-lasting uniforms |

| Sublimation Printing | Minimal | Detailed, durable designs, no cracking | Custom sports apparel |

Water-Saving Dyeing Methods Comparison: CO2, Dope Dyeing & Sublimation

Main Water-Saving Dyeing Techniques

The textile industry has introduced several methods to significantly reduce water use while maintaining or even improving fabric quality. These approaches are particularly effective for synthetic materials often found in sports apparel. This is a big step forward in creating durable, high-performance custom sportswear with less environmental strain.

Supercritical CO₂ Dyeing

This technique completely eliminates water by using supercritical CO₂ to dye fabrics. When CO₂ is heated above 88°F and pressurized beyond 74 bar, it enters a supercritical state, behaving like both a liquid and a gas. In this state, it dissolves dyes and penetrates polyester fibers, replacing water as the solvent.

The process is designed as a closed loop. Once the dyeing is done, the CO₂ is depressurized, turning back into gas, and is then captured for reuse in the next cycle. Since the fabric comes out dry, it skips energy-heavy drying stages, cutting the total process time to just two to three hours.

In 2024, the H&M Group began testing Deven Supercriticals’ "Suprauno" technology with Arvind Ltd. in India. Earlier trials on poly-cotton blends showed 76% less water use, 67% energy savings, and a 90% drop in chemical usage compared to traditional methods. Similarly, Ministry of Supply has reported saving over 130,000 gallons of water annually by adopting this method.

| Feature | Traditional Dyeing | Supercritical CO₂ Dyeing |

|---|---|---|

| Primary Solvent | Water | Supercritical CO₂ |

| Water Usage | 100–150 L per kg of fabric | Near zero (waterless) |

| Drying Required | High (energy-intensive) | None (fabric emerges dry) |

| Chemical Waste | High (effluent with dyes/salts) | Minimal (closed-loop recovery) |

| Process Time | Longer, varies | 2–3 hours |

This method has gained recognition for its effectiveness with polyester and single-color designs – key components in performance apparel. Next, let’s look at another dry method that integrates color during fiber production.

Dope Dyeing (Solution Dyeing)

Dope dyeing introduces color pigments directly into the liquid polymer before the fibers are even formed. Instead of dyeing finished yarns or fabric in water baths, the color becomes part of the fiber itself during production.

This approach eliminates the need for water-heavy dye baths and rinse cycles. Since the color runs throughout the fiber, dope-dyed fabrics are highly resistant to fading caused by UV exposure or repeated washing – a major plus for sports uniforms that face tough conditions.

The Swedish company We aRe SpinDye specializes in dope dyeing polyester yarns for global fashion and sports brands. As of 2024, they provide Life Cycle Assessment data that quantifies their savings in water and CO₂ emissions compared to traditional wet dyeing. Now, let’s explore a waterless method ideal for intricate designs.

Sublimation Printing

Sublimation printing uses heat and pressure to turn solid dye into gas, which bonds directly with polyester fibers at the molecular level. This results in the design becoming part of the fabric itself, rather than sitting on top. The process uses little to no water.

The benefits are clear: sublimated prints are highly durable and resist peeling, cracking, or fading, even after frequent washing and heavy use. The fabric retains its original breathability and moisture-wicking properties, with no added texture or "hand" feel. Unlike screen printing, sublimation allows for detailed, photorealistic designs with unlimited color options and no expensive setup costs.

For custom sports uniforms, sublimation is a game-changer. It’s perfect for small, personalized orders – like jerseys with individual names and numbers – while staying environmentally friendly and maintaining top-tier performance.

Benefits of Water-Saving Dyeing for Sports Apparel

Using water-efficient dyeing techniques not only lessens environmental strain but also enhances the durability and performance of sports uniforms.

Improved Durability and Performance

Water-saving methods like sublimation dyeing work by embedding the dye directly into the fabric’s fibers, rather than applying it as a surface layer. This process ensures that graphics, numbers, and logos become a permanent part of the garment. Unlike traditional methods, this approach preserves the fabric’s natural breathability and moisture-wicking properties.

"The nature of sublimation means that the prints are never heavy or thick. The garment is unchanged by the process, save for the addition of your art. It means that sublimated uniforms are much lighter to play in, offering players more comfort than conventional jerseys." – Wooter Apparel

This lightweight, seamless integration not only improves comfort but also opens the door to a wide range of design possibilities.

Custom Design Options

Sublimation offers creative freedom that traditional dyeing methods can’t match. With an unlimited color palette, teams can achieve vibrant, detailed designs, including photographic images and smooth gradients. This technique allows for all-over printing, covering every inch of the garment – front, back, and sleeves – with precision. Each piece is digitally customized, making it easy to permanently incorporate logos, player names, and numbers.

This flexibility is especially beneficial for small team orders, which can start at just 10 pieces. Wooter Apparel’s sublimated products have received an impressive 4.9/5 star rating from 1,239 reviews. Customers often highlight the bold colors, high-quality fabric, and how well the final designs match their expectations.

But the benefits don’t stop at design and performance – these methods also support sustainability efforts.

Meeting Environmental Goals

Water-saving dyeing techniques align perfectly with eco-conscious goals. Sublimation, for example, is a waterless process that eliminates dye waste, significantly reducing its environmental footprint. Additionally, the dye’s direct bond with the fabric ensures that designs stay vibrant and intact over time, extending the life of the apparel and minimizing textile waste.

"Sublimation printing is the most environmentally friendly and sustainable process possible for sports apparel, garment printing and production. It produces no wastage and water is not required for the sublimation process." – Wooter Apparel

sbb-itb-4d95ad3

How Wooter Apparel Uses Water-Saving Dyeing

Wooter Apparel has embraced water-saving dyeing techniques to redefine custom sportswear. By using sublimation printing – a process that doesn’t require water – they create custom uniforms with bold designs while significantly reducing environmental strain.

Sublimation Printing for Team Uniforms

Sublimation printing is Wooter Apparel’s go-to method for crafting custom sports uniforms, covering everything from basketball and football to baseball, softball, and soccer. The process involves heating solid dye to temperatures between 380–420°F, turning it into gas that fuses directly with polyester fibers. This results in permanent, vibrant designs that include unlimited colors, intricate gradients, and personalized details like player names and numbers. Whether you need a few pieces or a bulk order, sublimation printing delivers consistent quality. For example, custom V-Neck Basketball Jerseys start at $16.99 each, while reversible jerseys are priced at $24.99. Orders are typically completed and shipped within 2–3 weeks, offering a balance of quality and efficiency.

Commitment to Reduced Environmental Impact

By eliminating water from the dyeing process, Wooter Apparel addresses one of the textile industry’s biggest environmental challenges. Traditional dyeing methods can consume up to 200 tons of water to produce just 1 ton of fabric, contributing to 17–20% of global industrial water pollution. Sublimation printing, on the other hand, generates zero liquid waste and avoids water use entirely, even during cleaning. This not only supports eco-friendly practices but also ensures the designs are long-lasting, resisting fading, cracking, or peeling. The durability reduces the need for frequent replacements, further lowering the environmental footprint. Wooter Apparel’s approach highlights a shift toward more sustainable practices in textile production, aligning with broader efforts to minimize environmental impact while delivering high-quality sportswear.

Conclusion

Water-saving dyeing methods are reshaping how sports apparel is produced. Techniques like sublimation printing, supercritical CO₂ dyeing, and solution dyeing tackle some of the textile industry’s toughest environmental challenges while maintaining top-tier performance for athletic wear.

These approaches aren’t just about conserving resources – they also boost the quality and longevity of garments. For instance, solution dyeing embeds pigment directly into fibers, making fabrics resistant to fading and capable of withstanding heavy use. Similarly, sublimation printing fuses ink at the molecular level, ensuring designs don’t crack or peel, which extends the lifespan of apparel.

Another major advantage is the creative flexibility these methods offer. Digital textile printing and sublimation allow for endless color options, intricate gradients, and detailed patterns – all without chemical runoff or water waste. This means teams can create fully personalized designs – complete with graphics, names, numbers, and logos – while staying eco-conscious. The blend of sustainability with artistic freedom is redefining modern sportswear.

On the environmental front, the impact is substantial. Supercritical CO₂ dyeing slashes water use by up to 100% and cuts CO₂ emissions by roughly 40%. Solution dyeing reduces water usage by up to 60% and minimizes chemical reliance by as much as 90%, significantly decreasing toxic wastewater.

Consumer preferences also underline the importance of these sustainable practices. About 61% of shoppers say environmental certifications influence their buying decisions. This makes water-saving dyeing methods not just an ecological imperative but also a smart business strategy. These innovations deliver high-performance, vibrant, and customizable sportswear that meets the demands of athletes while aligning with global sustainability goals.

FAQs

What is supercritical CO₂ dyeing, and how does it save water?

Supercritical CO₂ dyeing is a process that uses carbon dioxide in a supercritical state – where it behaves like both a liquid and a gas – to dye fabrics. In this method, the dye dissolves into the CO₂, which then penetrates the fabric fibers and bonds the dye evenly, all without using water.

After the dyeing process is finished, the CO₂ is depressurized, reverting to its gaseous form and leaving behind beautifully dyed fabric. This approach not only eliminates water usage but also cuts down on energy consumption and waste, offering a more environmentally friendly alternative to traditional dyeing techniques.

What are the environmental advantages of dope dyeing?

Dope dyeing, often referred to as solution dyeing, is a process that integrates pigments directly into the polymer before the fibers are even formed. By doing this, it skips the need for traditional dye baths, dramatically cutting down on water usage and avoiding the release of polluted wastewater. Plus, it uses far fewer chemicals, making it a cleaner and more environmentally conscious option.

Because it eliminates the repeated soaking, rinsing, and drying stages of conventional dyeing, dope dyeing not only saves energy but also speeds up production. This streamlined approach helps lower the carbon footprint of textile manufacturing, making it an ideal choice for producing high-performance garments like custom sportswear.

What makes sublimation printing a great choice for custom sports apparel?

Sublimation printing stands out as a top choice for custom sports apparel because it embeds dye directly into polyester fabrics. This process creates vivid, full-color designs that are not only soft and breathable but also built to last. Unlike traditional printing methods, the dye becomes part of the fabric itself, meaning the designs won’t peel, fade, or wash out – even after heavy use.

What’s more, sublimation printing is incredibly efficient when it comes to water usage. Unlike conventional dyeing methods that require significant amounts of water, this process uses almost none, making it a more environmentally friendly option. It’s a win-win for creating durable, high-performance sportswear that looks sharp and can handle the demands of intense activity.