Designing jerseys that highlight motion involves blending style, functionality, and technology. Here’s a quick guide:

- Define Team Identity: Build the design around your team’s personality, values, and sport-specific needs. Logos, colors, and patterns should reflect this identity.

- Create Motion Patterns: Use elements like gradients, speed lines, and geometric shapes to convey energy. Test scalability and placement to ensure designs fit all jersey sections.

- Select Performance Fabrics: Opt for moisture-wicking, stretchable materials like polyester blends. These fabrics maintain comfort and durability during intense gameplay.

- Add Typography & Logos: Choose bold, legible fonts and place logos strategically to complement the design while ensuring readability.

- Prototype and Test: Produce samples to check fit, durability, and color accuracy. Gather player feedback to refine the final product.

- Finalize and Produce: Ensure compliance with league standards for numbers, fonts, and placements. Use sublimation printing for vibrant, long-lasting designs.

Step 1: Define Your Team’s Identity and Motion Concept

Before diving into design, you need to establish your team’s identity. A jersey should do more than just look good – it should embody your team’s personality, values, and the unique demands of the sport. For instance, a basketball team known for fast-paced play and aggressive defense might lean toward a bold, dynamic visual style, while a soccer team celebrated for precision and teamwork might opt for something more refined and cohesive. This groundwork is essential for guiding every design choice that follows.

Understand the Team’s Style

The starting point of any jersey design is your team’s core identity, with the logo serving as the centerpiece. Beyond that, selecting official colors is crucial. Specify Pantone codes to ensure the colors remain consistent across all production stages.

The design should also account for the sport’s specific movements. Basketball involves explosive jumps and rapid direction changes, while baseball emphasizes throwing and sliding. Sublimation printing is key here – it wraps patterns around the body seamlessly. As Wooter Apparel explains, "Designing sublimation sportswear is the process of… understanding how every flat design will later contour around the various shapes of a body". This ensures the design flows naturally with the athlete’s movements.

Research Dynamic Pattern Ideas

Once your team’s identity is clear, it’s time to explore patterns that visually represent motion. Speed lines, wave patterns, and gradient transitions can bring a sense of energy and movement to the jersey, even when players are standing still. These design elements not only add depth but also reinforce the idea of motion and dynamism.

For inspiration, consider the BRICK League Pro-Am in Columbus, Ohio. Between 2018 and 2021, they collaborated with Wooter Apparel to create basketball jerseys that perfectly aligned with their brand image. Using sublimation printing, they customized every inch of the uniform to ensure the designs moved seamlessly with the players. This example highlights how integrating motion-inspired designs with a team’s identity can elevate both style and functionality in sportswear.

Step 2: Develop and Test Dynamic Patterns

With your team’s identity established, it’s time to bring your motion concept to life by creating dynamic patterns that adapt smoothly to all jersey sizes and sections.

Create Initial Sketches and Mood Boards

Start by exploring visuals that naturally evoke motion. Geometric shapes – like stripes, chevrons, and angular designs – are excellent for conveying a sense of energy and cohesion. Layer these with gradients or color blocks to add dimension, using bold, high-contrast color combinations such as navy/white, black/red, or royal blue/gold for better visibility during gameplay. Refine your sketches to ensure the design works cohesively across every part of the jersey.

Test Pattern Scalability and Placement

After finalizing your initial sketches, the next step is to ensure your patterns look sharp and functional across all jersey sizes and sections. Tools like Adobe Illustrator or CorelDraw are ideal for this since they use vector graphics, which maintain quality regardless of scaling. As Wooter Apparel puts it, "By working with vector files, you can ensure that your designs are scalable without any loss of quality. This ensures crisp and sharp prints on your custom sports apparel".

Use sport-specific templates to test how the patterns flow across different jersey sections. Pay special attention to how the design adapts to garment contours, seams, and sleeve styles – whether raglan or inset. This ensures the pattern maintains its visual appeal even when stretched or compressed during gameplay. Proper placement and adaptability are key to keeping the design impactful on the field.

Step 3: Choose Performance Fabrics for Motion

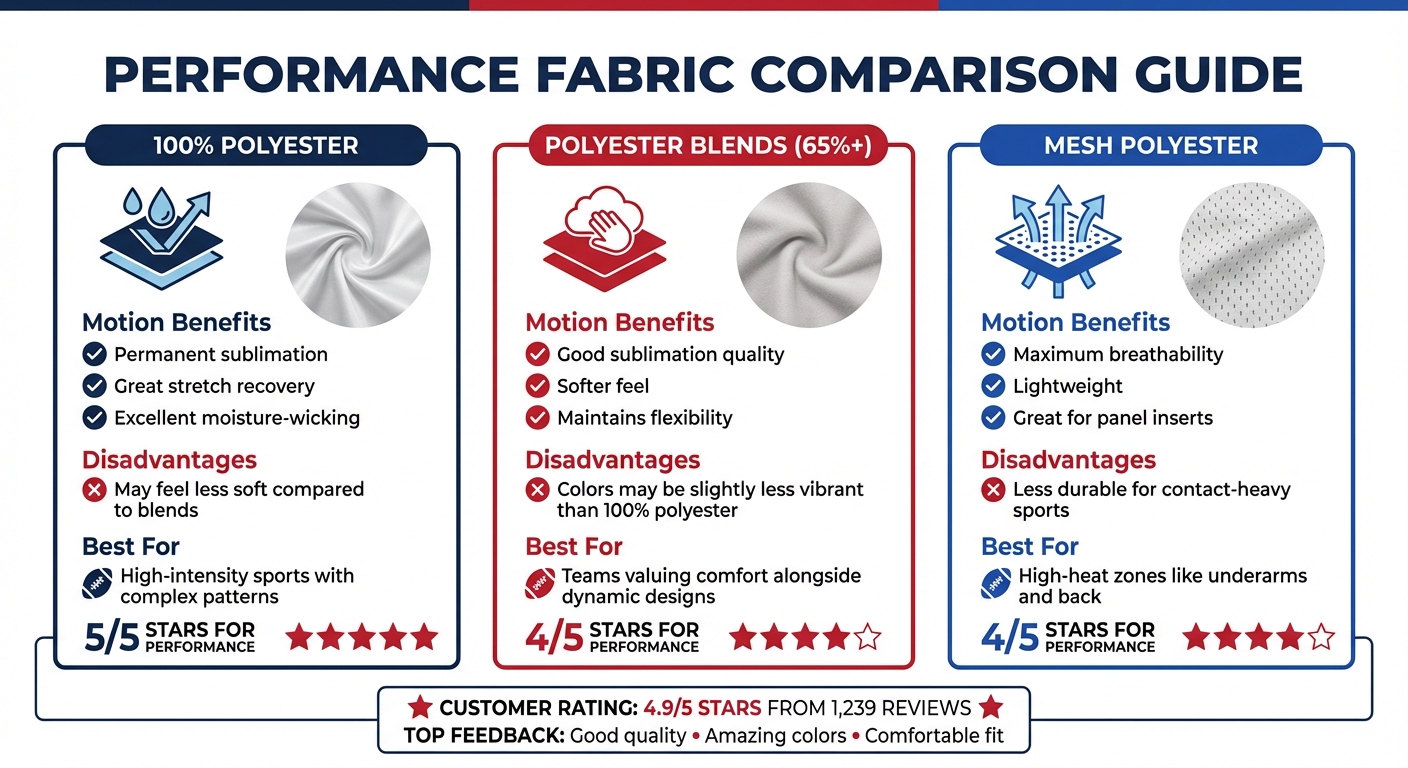

Performance Fabric Comparison for Motion-Inspired Jerseys

After testing your patterns, the next big step is picking fabrics that not only enhance performance but also keep your design intact.

Focus on Moisture-Wicking and Stretchable Materials

For the best results with dye sublimation and durability, opt for polyester blends with at least 65% polyester content. If your jerseys need to flex and move with the athlete, fabrics with 4-way stretch properties are a must. These materials stretch in all directions, reducing the chance of pattern distortion during intense gameplay.

To keep athletes cool, consider adding breathable mesh panels in areas prone to heat buildup, like the underarms and back. These panels improve airflow without compromising your design. Check fabric details on garment tags, and as Wooter Apparel suggests, always review your design on a 3D model or a tensioned sample to ensure proper pattern placement.

Compare Fabric Options

Each fabric type brings its own set of strengths, so it’s important to match the material to your team’s needs. Here’s a quick breakdown:

| Material/Method | Motion Benefits | Disadvantages | Suitability |

|---|---|---|---|

| 100% Polyester | Permanent sublimation, great stretch recovery, and excellent moisture-wicking | May feel less soft compared to blends | Best for high-intensity sports with complex patterns |

| Polyester Blends (65%+) | Good sublimation quality, softer feel, maintains flexibility | Colors may be slightly less vibrant than 100% polyester | Ideal for teams that value comfort alongside dynamic designs |

| Mesh Polyester | Maximum breathability, lightweight, great for panel inserts | Less durable for contact-heavy sports | Perfect for high-heat zones like underarms and back |

Wooter Apparel’s performance fabrics are highly rated, earning a 4.9/5 score from 1,239 reviews. Customers frequently praise their "good quality", "amazing colors", and "comfortable fit". One reviewer, Alex A., shared: "Most comfortable uniforms my players had".

Once you’ve chosen the right fabric, it’s time to seamlessly incorporate it into your jersey design.

Step 4: Integrate Typography and Logos Into the Design

Bring your team’s identity to life by incorporating text and logos into your jersey design. The key here is to balance style with functionality – your design should stand out without sacrificing readability during the game. By combining your fabric choice and dynamic patterns with thoughtful typography and logo placement, you’ll finalize a cohesive visual identity.

Use Bold, Easy-to-Read Fonts

Typography should work in harmony with the jersey’s motion patterns. For jerseys featuring sharp, angular designs, heavy block fonts can enhance the boldness and energy. On the other hand, if your design features smooth, flowing lines, modern sans-serif fonts with clean curves can complement that aesthetic perfectly.

To maintain visibility, follow these size guidelines:

- Adult jerseys: Back numbers should be 6–8 inches tall, with names sized at 2–3 inches.

- Youth jerseys: Scale back numbers to 4–6 inches and names to 1.5–2.5 inches.

For multicolored or busy designs, consider adding a 1- or 2-color outline around the text. This creates contrast, making the text pop against the background.

Position Logos Thoughtfully

Logos should not only represent your team but also enhance the overall design. Experiment with off-center or angled placements that follow the natural flow of the jersey’s contours. This approach can amplify the sense of motion and energy in your design.

To maintain consistent branding, use Pantone colors for your logos and text. This ensures that your colors remain uniform across different production runs and printing methods. As Wooter Apparel explains:

"Pantone is a global standard that ensures we’re all speaking the same language when we talk about color, allowing us to do a better job of producing the colors that you ordered".

sbb-itb-4d95ad3

Step 5: Prototype, Test, and Refine the Design

Building a physical prototype is a critical step in turning your design concept into reality. It allows you to test the design under real-life conditions, helping you identify potential issues with color accuracy, fit, and durability before committing to full production.

Test Dye Sublimation for Color Accuracy

To ensure your design looks exactly as intended, start with vector-based files (formats like AI, EPS, or CDR) and make sure all fonts are outlined. When it comes to colors, precision is key – especially for motion-inspired patterns. The Pantone Matching System is a trusted tool for standardizing colors. With over 200 shades for a single hue, like orange, Pantone codes ensure your colors remain consistent across different printers.

Once your prototype is printed using dye sublimation, conduct a thorough Quality Assurance (QA) test. This step ensures that the colors are reproduced accurately and that the construction quality meets your expectations.

After confirming the technical details, it’s time to gather real-world insights from the end users.

Gather Player Feedback

To test the fit and feel of your jerseys, consider ordering sizing kits. These kits, often available with a refundable deposit, let players try on the uniforms physically. Keep in mind that slight sizing variations can happen. As Patrick K., a Verified Buyer, shared:

"The uniforms were awesome, we could have got the sizes a little better, but no fault of Wooter overall we were impressed".

Have players wear the prototypes during practice to evaluate comfort, flexibility, and how well the design holds up in motion. Pay close attention to moisture-wicking performance and ensure the design remains visually striking under different lighting conditions. If any issues arise, inspect the prototypes immediately and report them within 30 days of delivery. This gives you enough time to make adjustments before moving forward with final production.

Step 6: Finalize and Produce Jerseys

Once you’ve fine-tuned your prototype based on player feedback, it’s time to move into full-scale production. This step ensures your motion-inspired jerseys meet all required standards and are manufactured with top-notch quality.

Verify Compliance With Sports Standards

Before placing your production order, double-check your league’s rulebook for specific requirements. Sports leagues often have strict guidelines for details like font styles, number sizes, and their placement. For instance, back numbers are typically positioned 2–3 inches below the collar seam, while player names are placed 1–2 inches above the number. Always measure from the collar seam, as it provides a consistent reference point across different jersey styles.

Readability is key for both officials and spectators. High-contrast color combinations – such as white text on dark jerseys – help ensure names and numbers are visible from a distance and under varying lighting conditions. To avoid surprises, test your design on a stretched sample of performance fabric to confirm proportions remain accurate during gameplay. Printing a single test jersey is also a smart move to verify placement, color accuracy, and measurements before committing to full production. These checks make for a smoother production process.

Leverage Wooter Apparel‘s Services

Wooter Apparel simplifies the production process with their free custom design services and advanced sublimation techniques. Their collaborative process is straightforward: submit a design brief through their request form, work with their in-house graphics team to refine the design (usually within 1–3 business days), and finalize your order for production. As Wooter explains:

"Pantone is a global standard that ensures we’re all speaking the same language when we talk about color, allowing us to do a better job of producing the colors that you ordered".

Custom uniforms typically take about 16 business days to produce, with rush options available in as little as 10 business days for an additional 25% fee. Every order undergoes a final Quality Assurance check, where uniforms are inspected before being labeled, packaged, and shipped. Customers frequently praise Wooter’s vibrant colors and high-quality sublimation, which ensures designs won’t peel, crack, or fade. Their systematic approach ensures your jerseys reflect the motion-inspired vision you’ve worked so hard to create.

For the best results, provide vector logos in formats like SVG, AI, EPS, PDF, or CDR, along with your primary colorways and specific Pantone values. This ensures your patterns retain their sharpness and visual impact throughout the production run.

Conclusion

Creating motion-inspired jerseys requires thoughtful planning and precise execution. Start with a strong team identity and a clear motion concept. From there, use vector-based tools like Adobe Illustrator or CorelDraw to design dynamic patterns that stay sharp at any size. These technical foundations pave the way for high-quality production.

The choice of materials and production methods plays a key role in crafting standout jerseys. Performance fabrics – moisture-wicking and stretchable – ensure comfort during intense gameplay while maintaining durability. Sublimation printing guarantees designs that won’t peel, crack, or fade over time. For precise color matching, always use Pantone reference colors.

Before finalizing your designs, make sure they comply with league standards for elements like number placement, font styles, and color contrast. Ordering sizing kits, which are often refundable upon return, ensures every player gets the right fit. Production typically takes about 16 business days, though rush options are available in 10 business days with a 25% surcharge. Testing prototypes and gathering player feedback can help fine-tune the final product before full-scale production.

Investing in quality design and production pays off both on and off the field. Teams with professional, eye-catching uniforms often attract attention and praise. As Feazel L., a Verified Buyer, shared:

"The players loved the uniforms. Everywhere we play people talk about our uniforms. We love them".

With a 4.9-star rating from 1,239 reviews, Wooter Apparel ensures your motion-inspired vision becomes a reality, delivering jerseys that excel in quality, performance, and style.

FAQs

How can I design a jersey that truly represents my team?

To design a jersey that truly represents your team, start by focusing on the essentials: your team’s name, mascot, logo, and official colors. Opt for bold, high-contrast color combinations to create a design that pops while staying true to your team’s identity. Adding custom symbols or patterns that reflect your team’s story or legacy can give the jersey a more personal and meaningful touch.

Working with professional designers, like those at Wooter Apparel, can help turn your ideas into a polished, custom design. Before making the final call, get input from your players to make sure the design feels right for everyone. This way, your jerseys won’t just look amazing – they’ll also inspire team pride and a sense of togetherness.

What materials are best for designing motion-inspired sports jerseys?

The best sports jerseys designed for dynamic movement use lightweight and breathable fabrics that balance moisture control, flexibility, and durability. Polyester mesh stands out as a go-to material because it keeps players cool, dries quickly, and retains vibrant sublimated designs without fading. To enhance stretch and maintain the jersey’s shape during intense activity, incorporating 5–10% spandex is a smart choice.

For added airflow during high-energy games, polyester blends with mesh-knit patterns are ideal. Teams looking for all-weather performance can explore advanced options like water-resistant laminates that still provide breathability and stretch. If sustainability is a priority, recycled polyester offers an eco-conscious alternative without sacrificing performance or quality.

Wooter Apparel specializes in premium fabrics tailored for custom sports jerseys. Their materials are designed to keep athletes comfortable while delivering bold, motion-inspired designs that move effortlessly with the action.

How can I ensure the jersey design is durable and fits well before production?

To make sure your motion-inspired jersey is both long-lasting and fits like a glove, start by creating a physical prototype using your finalized design and chosen fabric. Put its durability to the test by focusing on high-stress areas, running it through multiple wash cycles, and ensuring the graphics hold up against heat. For fit, compare the prototype’s measurements with your size chart and have athletes wear it while performing sport-specific movements. Take note of any durability or fit issues, make the necessary tweaks, and repeat the process if needed. Once everything checks out, give the green light for full production.