Team uniforms are more than just clothing – they represent identity, unity, and professionalism. But poor design choices can ruin their impact. Here are the most frequent mistakes teams make when designing uniforms and how to avoid them:

- Improper Fit: Uniforms that are too tight or loose hinder performance and look unprofessional. Always take accurate measurements and test samples before ordering.

- Skipping Team Input: Excluding players from the design process can lead to uninspired uniforms that don’t resonate. Gather feedback through surveys or brainstorming sessions.

- Overcomplicated Designs: Too many logos, patterns, or colors create a cluttered look. Stick to 2–3 colors and focus on one standout design element.

- Poor Color and Fabric Choices: Low-quality materials and clashing colors hurt both performance and appearance. Use durable, moisture-wicking fabrics and balanced color schemes.

- Lack of Proofreading: Typos, blurry images, and alignment issues can ruin an entire batch. Review mock-ups and order physical samples to catch errors early.

- Cheap Materials or Printing Methods: Subpar fabrics and printing lead to fading, cracking, and discomfort. Opt for sublimation printing and high-performance materials for long-lasting quality.

- Ignoring Scalability: Designs that don’t scale well across sizes or are poorly placed can look inconsistent. Test designs on various sizes and ensure proper placement.

7 Common Uniform Design Mistakes Teams Make and How to Avoid Them

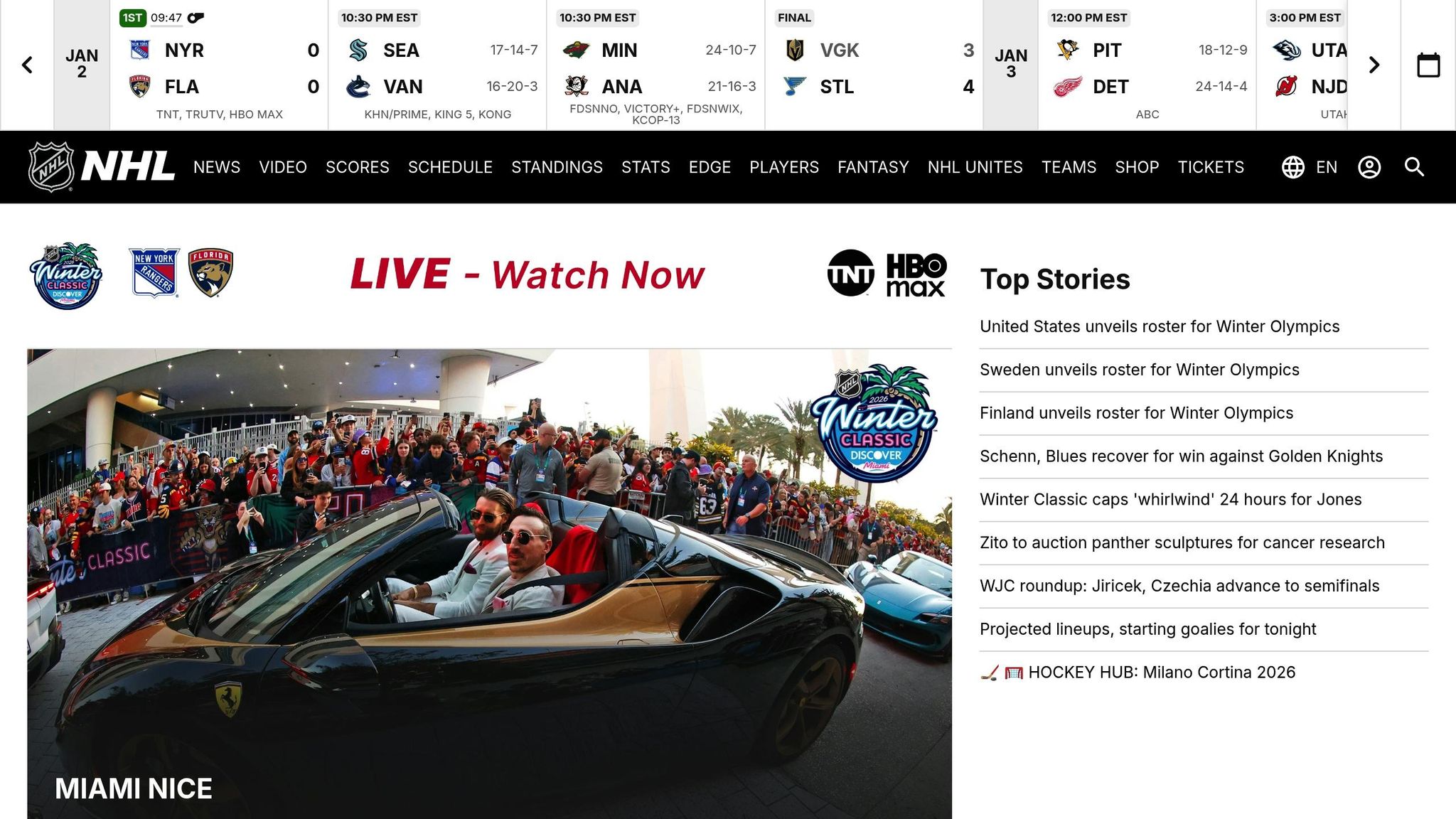

TOP 10: NHL Brand Blunders

Mistake 1: Ignoring Proper Sizing and Fit

Assuming that one-size-fits-all uniforms will work for every athlete is a big mistake. Athletes come in all shapes and sizes, and forcing everyone into the same fit leads to discomfort, impacts performance, and gives the team an unpolished look. As Colourup Uniforms puts it:

An ill-will fitting T-shirt not only sounds unprofessional but may also affect the efficiency of the players.

Skipping proper measurements and opting for bulk orders without checking sizes results in uniforms that restrict movement and look unprofessional. This issue doesn’t just affect appearance – it directly impacts how athletes perform.

How Poor Fit Affects Performance

Ill-fitting uniforms can create major challenges during games. Tight uniforms limit an athlete’s ability to move freely, making actions like running, jumping, or swinging more difficult. On the other hand, loose uniforms can create drag or even get caught in equipment, which can be dangerous. Areli Sportswear highlights this issue perfectly:

A uniform that looks great but fits poorly is a disaster waiting to happen. Too tight, and players can’t move. Too loose, and it looks sloppy.

Beyond the physical issues, poorly fitted uniforms can be distracting. Athletes may lose focus or confidence if they’re constantly adjusting their clothing. In contrast, a well-fitted uniform boosts team morale and helps players feel more professional and prepared.

Solution: Take Accurate Measurements and Order Samples

The solution is straightforward: prioritize accurate measurements. Use a flexible measuring tape and have someone assist to ensure precision. Keep in mind that different sports require specific measurements. For example, basketball and baseball uniforms need chest, waist, hip, and inseam measurements, while football uniforms should also account for shoulder width and areas where padding will be worn.

Another key step is to request sample uniforms or fit kits before committing to a bulk order. These samples let players test the fit and see how the design works with the actual fabric. Confirm sizing with players and families to ensure everyone gets a uniform that fits well. Offering multiple size options ensures comfort, enhances performance, and keeps the team looking sharp. At Wooter Apparel, precise measurements are a cornerstone of our approach, helping teams perform at their best while looking unified and professional.

Mistake 2: Rushing the Design Process Without Team Input

When one person takes sole control of designing uniforms, the outcome often misses the mark in reflecting the team’s identity and values. Beyond just how the uniforms look, leaving the team out of the process can hurt their sense of ownership. As GetBold points out:

If you don’t ask the team what they think, they may not buy into the uniform idea at all. The only way this works is through compliance and showing that you respect their ideas.

This lack of involvement can lead to morale issues and weaken team unity. It’s not just about aesthetics – excluding the team can dilute what makes them unique and open the door to more design challenges down the road.

What Happens When Teams Are Left Out

Skipping team input creates a ripple effect of problems. Decisions often end up reflecting personal preferences rather than practical needs, leading to designs that might be uncomfortable or just plain uninspiring. Areli Sportswear sums it up perfectly:

A generic design without any personal touches won’t inspire pride or excitement.

Without key elements like team colors or mascots, the uniforms lose their significance. They become just another outfit, rather than a unifying symbol that players can rally around. Including the team in the process ensures the final design feels meaningful and energizes everyone who wears it.

Solution: Surveys and Feedback Sessions

To avoid these pitfalls, start by gathering input from the team. Use surveys, polls, or brainstorming sessions to get their thoughts on colors, design features, and functionality. This not only shows that their opinions matter but also makes them more likely to embrace the final product. Tools like email surveys or social media polls can make collecting feedback quick and easy.

Once you’ve gathered ideas, collaborate with a custom design service to create digital mock-ups. These previews allow the team to see how their input translates into the actual uniform before it goes into production. At Wooter Apparel, for example, our free custom design services make it simple to turn team feedback into polished mock-ups. Hosting feedback sessions where players can review and suggest changes ensures the final design reflects the team’s vision and values.

Mistake 3: Overcomplicating Uniform Designs

When teams try to cram every idea into their uniforms – think excessive logos, patterns, and mottos – it often results in a cluttered, chaotic look. This kind of design not only dilutes the uniform’s visual appeal but also weakens the brand’s identity. As Real Thread puts it:

A clean, simple design not only looks professional but makes a stronger impact.

Overly complex designs can also confuse your message. When too many elements compete for attention, nothing stands out. This muddles the story your uniform is trying to tell, making it harder for fans, opponents, and even your own players to connect with its meaning.

Why Simple Designs Work Better

Clean, minimal designs consistently shine over cluttered ones. The most iconic sports uniforms rely on bold, recognizable elements rather than overwhelming graphics. A single, strong design feature makes a bigger impact than a mix of competing ideas. Erik Mickelson, Founder of Apparel Graphic Academy, sums it up:

One bold element often says more than a messy mash-up of ideas. Less really is more.

Simplicity also ensures better scalability. A clean basketball jersey with sharp, high-contrast lines looks great whether you’re sitting courtside or way up in the bleachers. In contrast, uniforms overloaded with decorative fonts and intricate graphics can blur together even at a short distance.

A professional appearance goes beyond aesthetics – it affects team morale. Poorly designed uniforms can feel cheap, impacting player pride and satisfaction, and ultimately influencing performance and public perception. Prioritizing simplicity not only enhances the visual impact but also sets a solid foundation for choosing the right colors and materials later on.

Solution: Limit Colors and Graphics

Stick to a palette of 2–3 colors for your uniform. A limited color scheme forces thoughtful choices and avoids the muddy, confusing appearance that can weaken your brand’s recognition.

Focus on one standout design element, like a bold team name, a striking mascot, or a clean geometric pattern. Let this primary feature take center stage, with the rest of the design playing a supporting role.

Typography matters, too. Use bold, sans-serif fonts or clean scripts with good spacing. Avoid decorative fonts that become unreadable from a distance. A quick trick: test your design in grayscale to ensure strong contrast under different lighting conditions.

Finally, always request prototypes to see how the design translates to fabric. What looks great on a screen might not work as well in real life. For instance, screen printing works best for bold, simple designs but struggles with fine details, while embroidery can distort small text or intricate graphics. Reviewing samples helps you catch these issues before production.

At Wooter Apparel, we prioritize clean, bold designs that highlight your team’s identity while ensuring top-notch performance on the court.

Mistake 4: Poor Color and Fabric Choices

Even the most well-thought-out uniform designs can fall apart with bad color choices or subpar fabrics. Clashing color combinations – like lime green paired with red – can create a jarring visual effect that detracts from your team’s professional image. Similarly, unappealing palettes, such as yellow and brown, can leave a negative impression.

Low-quality fabrics only make matters worse. Materials that fade, crack, or peel not only appear cheap but can also hinder performance by restricting movement. Stiff or scratchy fabrics can ruin even the most polished designs. Erik Mickelson, Founder of the Apparel Graphic Academy, sums it up perfectly:

You can have the slickest design out there, but if it’s printed on a stiff, scratchy shirt – it’s a flop.

Another common issue is poor color placement. Flesh-colored or light-pink fabrics in the wrong areas can create awkward visual effects, making athletes appear partially nude. Misplaced color blocks or asymmetrical designs can also create optical illusions, leaving players looking off-balance. Using color theory can help prevent these design missteps.

How Color Theory Applies to Uniform Design

Colors aren’t just visual – they carry meaning. Blue suggests trust, red conveys boldness, and green hints at eco-consciousness. Ignoring these associations can lead to what Real Thread describes as a "clown college" aesthetic instead of a cohesive team identity. Contrast is just as important. High-contrast combinations ensure team numbers and logos are easy to read, but the colors still need to work together harmoniously. For example, while countries like Jamaica and Brazil successfully use bold green-and-gold palettes, poor shade selection can lead to uniforms that some might label as "awe-inspiringly bad." Similarly, muddy or generic color combinations can make uniforms look like a "muddy picnic blanket", diminishing team recognition.

Solution: Choose High-Quality Fabrics and Colors

Start with sublimation printing, a technique that embeds colors directly into the fabric. This ensures designs stay vibrant and don’t fade, crack, or peel over time. At Wooter Apparel, fully sublimated uniforms maintain their professional look season after season.

Select fabrics tailored to your sport. For athletic wear, moisture-wicking polyester blends are ideal – they keep sweat at bay and allow for full mobility. For contact sports like football, prioritize durable materials, while sports like baseball or basketball benefit from lightweight, high-mobility fabrics.

Use a color wheel to find balanced, complementary combinations. Test your palette in grayscale to ensure visibility in various lighting conditions. Sticking to two or three colors can improve clarity and make the design more impactful.

Finally, always order physical samples before committing to production. Samples let you see how colors look on the actual fabric, check the material’s weight and stretch, and confirm that the design translates well from screen to reality. What looks great digitally might not hold up in person. By making these thoughtful choices, you can create uniforms that not only perform well but also reflect your team’s identity with professionalism and style.

sbb-itb-4d95ad3

Mistake 5: Skipping Proofreading and Test Prints

Imagine this: a single typo sneaks into your design, and suddenly, an entire batch of uniforms is unusable. What looks fine on screen can turn into a glaring mistake on fabric. Spelling errors, for instance, often go unnoticed until after mass production – when it’s too late to fix.

But the issue isn’t just about spelling. Fonts that look sharp on a monitor might become unreadable when printed. Low-resolution images can turn into blurry messes, and vibrant colors on a screen might lose their punch on fabric. Without a test print, you might even find your logo awkwardly placed – like sliding into the armpit – or sized incorrectly for different garment sizes.

"Typing errors can be disastrous. Even a single typing error on all sports jerseys can turn the whole batch of uniforms useless."

- Colourup Uniforms

Common Printing Errors to Watch For

Here are some common pitfalls to keep in mind:

- Typographical errors: A misspelled team name or incorrect player number can instantly make a batch of uniforms look unprofessional.

- Font legibility issues: Fonts that are too small, overly decorative, or poorly spaced can become unreadable, especially from a distance.

- Image quality problems: Designs created with low-resolution files often appear blurry or pixelated when printed.

- Color discrepancies: Digital designs don’t always translate perfectly to fabric, with some colors losing their intended contrast.

- Alignment flaws: Without a physical test, logos or designs can end up crooked or awkwardly placed on the garment.

These mistakes highlight why a thorough review process is so crucial before hitting "print" on a large order.

Solution: Review Mock-Ups and Order Samples

Start with digital mock-ups to catch obvious errors like misspellings or poor layouts. Have at least two people review the design – preferably someone who wasn’t involved in its creation. A fresh set of eyes can spot mistakes that others might miss.

Next, print the design at full size on regular paper and hold it up to a shirt or even a person. Step back and see if the text is readable from a distance. This simple step can uncover scaling issues that aren’t obvious on a computer screen.

"Ordering a batch without a test run is as risky as buying shoes without checking the size guide."

- Real Thread

Finally, order a physical sample before committing to bulk production. A full custom sample lets you evaluate how colors appear on fabric, how the material feels, and whether the design placement works across different sizes. If time allows, wash and wear the sample to ensure the design holds up – no cracking, peeling, or fading. At Wooter Apparel, for instance, fully sublimated printing embeds colors directly into the fabric, ensuring long-lasting and vibrant results.

Mistake 6: Choosing Low-Quality Materials or Printing Methods

Cutting corners with cheap materials might save a few bucks upfront, but it can lead to higher costs down the road. Just like other aspects of uniform design, the quality of materials plays a big role in how well the uniforms hold up over time. A low-cost purchase often turns into a recurring expense when replacements are needed season after season.

But it’s not just about the budget – low-quality uniforms can also hurt team morale and image. Players notice when their jerseys lose shape or when logos start peeling off mid-game. As GetBold explains:

Cheap clothing affects not only employee performance but job satisfaction as well. It reveals a lack of sophistication and knowledge… after just a few wearing’s and washings, the garment loses its shape.

When a team’s uniforms look unprofessional, it impacts their confidence and how they’re perceived by others.

Problems with Low-Quality Materials

What might seem like a cost-saving decision quickly becomes a problem when the uniforms start to degrade. Poor-quality materials lead to issues like blurry or faded designs, cracked and peeling logos, colors that bleed or wash out, and seams that fail, leaving the garments unfit for wear.

Performance also takes a hit. Fabrics that are heavy or lack breathability can make physical activity uncomfortable, leaving players overheated, distracted, and less effective on the field.

As Areli Sportswear points out:

Designs that fade, crack, or peel after a few uses aren’t just disappointing; they’re a waste of money.

Solution: Use Fully Sublimated, Durable Fabrics

Sublimation printing is a game-changer for team uniforms. Instead of the design sitting on top of the fabric, sublimation embeds the ink directly into the material. This ensures that designs won’t fade, crack, or peel over time. It’s also perfect for creating the bold, colorful designs that teams love, delivering a vibrant look that lasts.

For the best results, pair sublimation with high-performance fabrics like 100% polyester or polyester-spandex blends. These materials are designed for durability, moisture-wicking, and comfort. For example, fabrics like 220gsm Swiss Pique offer a balance of softness and structural integrity, keeping their shape and appearance even after repeated use. Always request samples to check fabric weight, seam strength, and print quality before committing.

At Wooter Apparel, you can get fully sublimated uniforms starting at just $16.99 per item. This gives you professional-grade quality without stretching your budget. Investing in durable, high-quality uniforms means they’ll last for multiple seasons, saving you money in the long run while boosting your team’s performance and image.

Mistake 7: Failing to Plan for Scalability and Print Placement

Even the most eye-catching designs can fall flat if they aren’t scaled correctly or placed thoughtfully. A logo that looks fantastic on a medium jersey might seem out of place on an extra-large one, or it could dominate a small youth uniform. These missteps can lead to an inconsistent and unpolished look, which can hurt your team’s overall image.

Problems with Poor Scaling and Misaligned Placement

When scalability isn’t considered, the issues are hard to miss. Logos that feel too small on large jerseys or overly large on smaller ones, combined with awkward placements – like being positioned too low or near the armpit – can make uniforms look unprofessional and inconsistent. Even text can lose its clarity when reduced in size. As Erik Mickelson, Founder of Apparel Graphic Academy, explains:

Size and placement are make-or-break details. Go too small, and it looks lost. Too big, and it overwhelms the shirt.

It’s not just about aesthetics. Poor scaling can also impact functionality. Uniforms designed with a one-size-fits-all approach may restrict movement, making it harder for players to perform at their best. To avoid these pitfalls, careful planning is essential before production begins.

Solution: Plan Design Proportions and Placement

The best way to catch scaling issues early is to request physical samples before placing a large order. This allows you to see how the design looks on actual fabric across various sizes. Professional printers often provide placement guides and templates to help you determine the ideal spots for logos on the chest, back, or sleeves.

Printing mock-ups at full scale and reviewing them from a distance ensures that all text and graphics remain clear and visually appealing. Avoid a one-size-fits-all approach by offering at least three size variations to keep designs proportional and functional for every team member. Collaborate with designers to choose printing techniques like sublimation, which embeds ink directly into the fabric. This method ensures vibrant, long-lasting designs that won’t crack or peel, regardless of size or placement.

At Wooter Apparel, the design team can help you preview how your graphics will look across different uniform sizes and styles before production. With fully sublimated uniforms starting at $16.99 per piece, you can achieve professional-quality designs that scale beautifully and maintain their impact across your entire team roster.

Conclusion

Designing team uniforms involves much more than picking colors and slapping on a logo. The pitfalls outlined here – ignoring proper sizing, rushing the process without team input, overcomplicating designs, choosing unsuitable fabrics or colors, skipping proofreading, using subpar materials, and failing to plan for scalability – can negatively impact your team’s comfort, performance, and overall image. As Real Thread aptly states, "Investing in high-quality materials is essential for durability and comfort, which means people will actually want to wear your designs".

These mistakes highlight the importance of a careful and deliberate design process. Keep in mind that most custom apparel vendors don’t allow returns or refunds once production starts, and cancellation fees can reach up to 100% of the order cost. Even a small typo or a sizing misstep can render an entire batch unusable, leading to wasted time and money. With average production times of 20–25 business days, catching errors late can delay delivery by another 3–5 weeks.

To steer clear of these costly setbacks, fine-tune your approach. Order samples, get input from your team, and carefully proofread mock-ups to ensure the final product is polished, fits well, and lasts through the season. Using quality materials and techniques like sublimation ensures designs resist fading, cracking, and peeling.

At Wooter Apparel, we offer free custom design services and fully sublimated uniforms starting at $16.99 per piece. With a 4.9/5 star rating from 1,238 reviews, we’re committed to providing uniforms that enhance both team identity and performance. By addressing these common mistakes with a thoughtful, team-oriented process, your uniforms can go beyond aesthetics – they’ll foster durability, satisfaction, and unity for your players.

FAQs

What’s the best way to ensure team uniforms fit perfectly?

To get the best fit for your team uniforms, start by taking precise measurements for each player. Focus on key areas like chest, waist, sleeve length, and shoulder width. Use a flexible tape measure and make sure players wear light clothing while measuring. Once you have the numbers, double-check them and compare them against the size chart provided by the uniform supplier.

If you want to be extra thorough, organize a team fitting session. This gives players the chance to try on sample sizes, consider their personal preferences, and check for comfort – especially with fabrics that may stretch or fit differently. These steps go a long way in making sure everyone feels comfortable and confident in their uniform.

Why is it important to involve the team in the uniform design process?

Getting the team involved in the uniform design process ensures it meets their priorities for performance, comfort, and identity. Plus, it builds a sense of ownership and pride. By collaborating, you can sidestep design missteps and create a uniform that fits properly and feels right for everyone. The result? A uniform that not only strengthens team spirit but also balances style and practicality, whether on the field or off.

What makes sublimation printing a great choice for team uniforms?

Sublimation printing is known for delivering bright, durable colors that stand the test of time. Unlike other methods, the designs won’t fade, crack, or peel, as they become part of the fabric itself. This creates a smooth, lightweight finish that feels natural and doesn’t add any extra weight.

Another advantage is its ability to produce full-coverage, seamless designs, ensuring every uniform piece looks polished and cohesive. From bold team logos to intricate patterns or personalized names and numbers, sublimation guarantees sharp, high-quality results that make an impression both on and off the field.