Recycled fabrics are transforming how team uniforms are made. They reduce waste, use materials like plastic bottles, and deliver durability comparable to virgin polyester. Here’s what you need to know:

- Why Recycled Fabrics? They cut down on waste, lower carbon emissions, and create long-lasting uniforms.

- Key Fabric Types: Recycled polyester (rPET) offers high durability and moisture-wicking, while cotton blends are softer but less effective for active sports.

- Design Process: Start with clear goals, use certified materials like OEKO-TEX, and rely on sublimation printing for sharp, lasting designs.

- Cost Efficiency: custom uniforms made from recycled materials can start as low as Custom uniforms made from recycled materials can start as low as $16.996.99, with full packages available for $199.99.

Recycled fabrics provide a way to combine performance and eco-conscious choices. This guide explains how to design and produce effective team gear using these materials.

Designer Makes Clothes From Recycled Materials

sbb-itb-4d95ad3

Benefits of Using Recycled Fabrics for Team Uniforms

Understanding these benefits can shape every aspect of creating sustainable team uniforms.

Environmental Impact

Choosing recycled fabrics helps reduce material waste and promotes eco-friendly practices. Sublimated uniforms are built to last, which means fewer replacements and less gear ending up in landfills over time. This approach not only supports sustainability but also ensures teams get reliable, high-performing uniforms.

Performance and Durability

Recycled polyester delivers the same performance as virgin polyester, making it perfect for athletic wear. Sublimation printing keeps player details sharp and intact, avoiding issues like peeling or fading. Combined with expert stitching and rigorous quality checks, these uniforms offer both comfort and durability. Plus, they’re designed to fit true-to-size, giving athletes the mobility they need to perform at their best.

Cost-Effectiveness

Durable designs mean fewer replacements, saving teams money in the long run. Recycled fabric uniforms provide excellent value while allowing for full customization. Thanks to advanced sublimation printing, teams can achieve intricate and precise designs without breaking the bank. For instance, custom basketball uniforms start at $30.58, while soccer jerseys are priced at $29.99. Uniform packages like the Pro Package ($99.99) and MVP Package ($199.99) offer comprehensive options for teams. Accurate sizing minimizes ordering mistakes, and with a standard production turnaround of 16 business days, teams can stay on schedule.

Choosing the Right Recycled Fabrics for Sports Uniforms

The type of recycled fabric you choose plays a major role in how sports uniforms perform. It impacts everything from moisture control and durability to how well players can move on the field.

Recycled Polyester (rPET)

Recycled polyester, or rPET, is a go-to choice for sports uniforms because it’s breathable and wicks away moisture effectively. It’s also built to last, making it ideal for high-performance gear like pro football jerseys or baseball jerseys. For instance, a 220gsm Swiss Pique made from 100% polyester offers a premium feel and stands up to wear and tear.

What’s more, rPET works seamlessly with sublimation printing, so logos, names, and numbers stay sharp and vibrant. If you’re aiming for bold, vivid colors, 100% recycled polyester is your best bet. On the other hand, a 65/35 polyester-cotton mix creates a more muted, retro vibe.

Recycled Cotton Blends

Recycled cotton blends shine when it comes to off-field apparel, where softness and comfort matter most. While these blends feel great, they don’t have the moisture-wicking power needed for active sports.

If you’re using sublimation printing, it’s worth noting that the ink adheres only to synthetic fibers. For example, a 65% polyester and 35% recycled cotton blend will result in about 65% of the ink bonding to the fabric. This creates a soft, vintage look that becomes even more pronounced after washing.

Comparison Table: Recycled Fabric Types

| Fabric Type | Durability | Breathability | Moisture-Wicking | Environmental Impact | Sublimation Compatibility |

|---|---|---|---|---|---|

| Recycled Polyester (rPET) | High | High | High | Reduces plastic waste | Excellent (Best at 100%) |

| Recycled Cotton Blends | Moderate | High | Low | Very low impact | Moderate (Vintage look) |

| Hemp Blends | Very High | High | Moderate | Lowest (Carbon negative) | Low (Requires treatment) |

Now that you’ve got a clear picture of the fabric options, the next step is to incorporate these materials into your uniform designs. Up next, we’ll break down how to design uniforms that balance sustainability and performance.

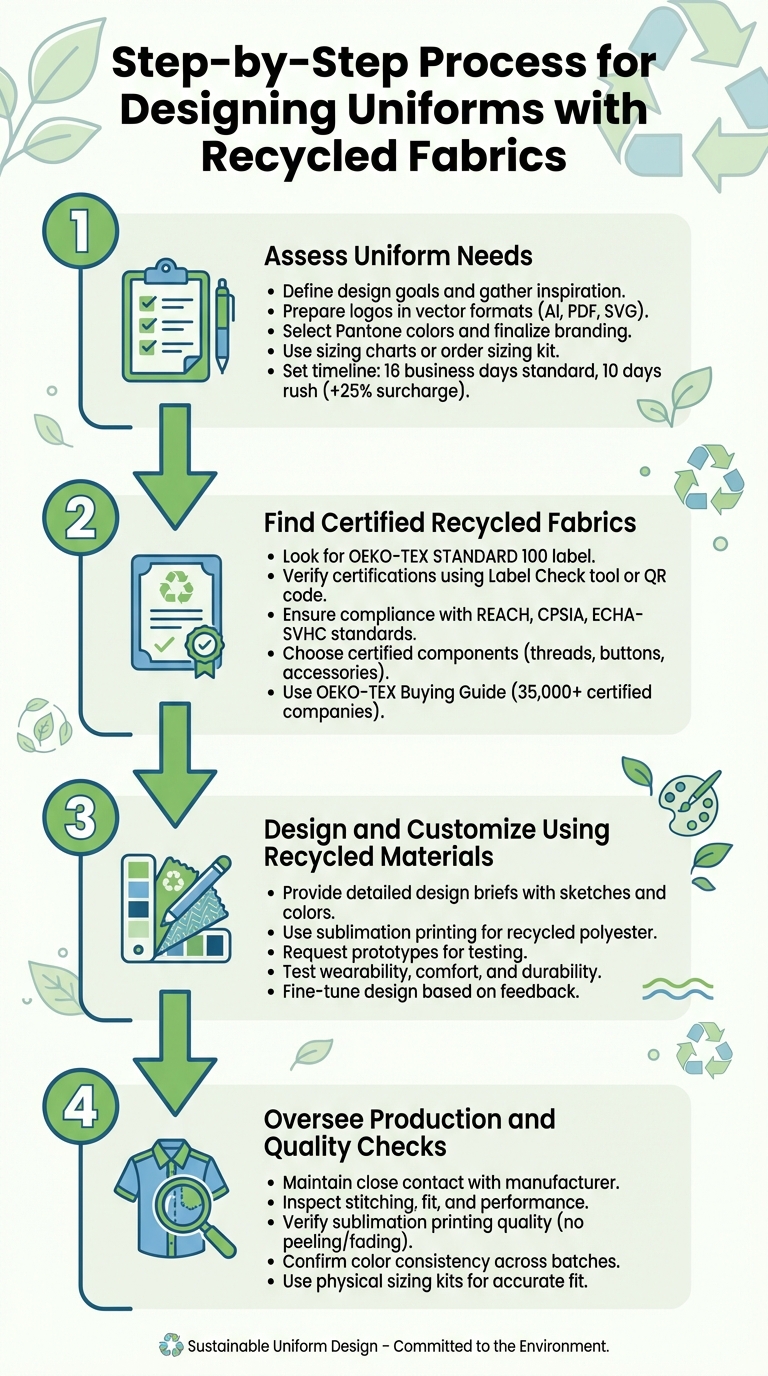

Step-by-Step Process for Designing Uniforms with Recycled Fabrics

4-Step Process for Designing Uniforms with Recycled Fabrics

Creating uniforms from recycled materials requires a careful balance of sustainability and functionality. Here’s a clear roadmap to take your idea from concept to completion.

Step 1: Assess Uniform Needs

Start by outlining your design goals. Gather inspiration from custom collegiate football jerseys, professional teams, social media, or your previous designs. Once you have a vision, dive into the specifics. Ensure all logos are in high-quality vector formats like AI, PDF, or SVG for crisp printing.

Next, pick exact colors using the Pantone system and finalize branding elements such as team names, city abbreviations, and outlined fonts for clarity. Use standardized sizing charts or order a sizing kit, typically available with a refundable deposit.

Set your timeline early. Standard production takes 16 business days, while rush orders can be completed in 10 days with a 25% surcharge. With these details in place, you’re ready to source eco-friendly fabrics.

Step 2: Find Certified Recycled Fabrics

Ensure the materials you choose meet rigorous safety and environmental standards. Look for fabrics with the OEKO-TEX STANDARD 100 label, which guarantees they’ve been tested for over 1,000 harmful substances. You can verify certifications using the OEKO-TEX Label Check tool or by scanning the QR code on the fabric label. The OEKO-TEX Buying Guide is a helpful resource, listing over 35,000 certified companies.

"Every item bearing the STANDARD 100 label is certified as having passed safety tests for the presence of harmful substances." – OEKO-TEX

Double-check that the fabrics comply with global standards like REACH, CPSIA, and the ECHA-SVHC candidate list. For components like threads, buttons, and accessories, opt for items that are already certified. If every element of the garment is certified, testing for the final product might not be required.

Once you’ve secured verified materials, you can begin designing.

Step 3: Design and Customize Using Recycled Materials

Work closely with your team to create a design that reflects your identity. Provide detailed briefs that include graphic sketches, reference colors, and even elements of team history to guide the creative process. Sublimation printing is ideal for recycled polyester, as it embeds designs directly into the fabric fibers.

Before moving forward, request a prototype. This allows you to test the uniform’s wearability, comfort, and durability in real-life conditions. As one customer noted:

"I ordered some prototypes so I could gauge their wear and make some tweaks. What they sent were above expectation." – Duane R.

This trial run gives you the chance to fine-tune the design and fit based on performance feedback.

Step 4: Oversee Production and Quality Checks

Stay in close contact with your manufacturer throughout production to ensure consistency in color and design. Sublimation printing ensures designs won’t peel, crack, or fade, which is especially important for maintaining the polished look of recycled fabrics.

Implement a thorough Quality Assurance process to inspect stitching, fit, and overall performance before the uniforms are shipped. Proper sizing is critical – not only does it reduce wear and tear on seams, but it also extends the garment’s lifespan. Physical sizing kits are especially useful, as recycled fabrics may have unique stretch properties that digital charts can’t account for.

Lastly, confirm that colors remain consistent across all material batches to uphold your brand’s visual identity.

Recycled Fabric Integration at Wooter Apparel

Wooter Apparel has embraced eco-friendly practices by incorporating recycled fabrics into its production process. Using sublimation printing, they seamlessly blend recycled materials into their designs. This approach reflects their commitment to sustainability and has earned them an impressive 4.9/5 star rating from 1,238 reviews.

How Recycled Fabrics Work with Sublimation Printing

Recycled polyester (rPET) is an ideal match for sublimation printing. The ink bonds directly to the fabric, creating long-lasting designs. To ensure consistent results, Wooter Apparel relies on the Pantone Matching System, guaranteeing uniform colors across fabric batches.

Before shipping, every product goes through a thorough Quality Assurance process. This includes checks for stitching strength, color precision, and overall performance, ensuring every item meets their high standards.

Popular Products with Recycled Materials

Wooter Apparel uses top-tier 220gsm Swiss Pique recycled polyester in its products. From Custom V-Neck Basketball Jerseys starting at $16.99 to Complete Team Uniform Packages priced at $199.99, the entire catalog can be made with recycled materials – without sacrificing performance or durability.

Each uniform is designed to fit true to size, making the transition to recycled fabrics effortless for teams. Whether you’re gearing up for basketball, football, baseball, softball, or soccer, these recycled polyester options deliver reliable durability and performance your team can count on.

Conclusion

Creating uniforms with recycled fabrics combines functionality, durability, and a polished team identity. Blends of recycled polyester (rPET) and cotton offer a sustainable option that rises to the challenges of competitive sports.

Thanks to advanced sublimation printing, teams can achieve sharp, customized designs – whether it’s matching precise Pantone colors or adding unique logos – that help establish a unified and eco-conscious brand.

"Stand out with personalized designs that not only look great but also enhance your performance." – Wooter Apparel

Every product reflects this commitment to quality. With custom basketball jerseys starting at $16.99, Wooter Apparel makes upgrading your team’s look easy and affordable. Whether you’re gearing up a basketball squad, football team, or soccer club, recycled polyester provides the comfort and resilience athletes need.

Take the step toward sustainability and redefine your team’s identity. Request a free custom design at https://wooter.com and see how recycled fabrics can elevate your team’s style, performance, and environmental commitment.

FAQs

What are the benefits of choosing recycled fabrics for team uniforms?

Using recycled fabrics, like polyester made from post-consumer plastic bottles (rPET), brings both practical and environmental advantages. For starters, producing rPET uses about 59% less energy and cuts CO₂ emissions by roughly 32% compared to creating new polyester. Plus, each uniform crafted with rPET helps keep dozens of plastic bottles out of landfills and oceans, transforming waste into durable, functional sportswear.

What’s even better? Recycled polyester matches the high-performance qualities athletes count on. It offers moisture-wicking and quick-drying properties, vibrant colors that hold up over time, and impressive durability. This means uniforms maintain their quality longer, reducing how often they need to be replaced – saving money in the long run. Choosing recycled fabrics allows teams to support eco-friendly practices without compromising on performance or reliability.

What makes sublimation printing ideal for creating durable uniforms with recycled fabrics?

Sublimation printing embeds dye directly into the polyester fibers of recycled fabrics. Instead of sitting on the surface, the design becomes part of the material, ensuring it resists fading, cracking, or peeling – even with frequent washing or heavy use.

This method delivers bold, enduring colors and patterns that stand the test of time, making it a top pick for eco-conscious, durable uniforms.

What factors should I consider when choosing between recycled polyester and cotton blends for sports uniforms?

When choosing between recycled polyester (rPET) and cotton blends for sports uniforms, it’s essential to weigh factors like performance, durability, and environmental impact. Recycled polyester stands out for its moisture-wicking and quick-drying properties, making it a great choice for high-intensity activities. It also holds its shape and color over time, offering better resistance to fading and wear compared to cotton blends. Cotton, while soft, tends to feel heavier and absorbs moisture, which can lead to discomfort during games.

On the sustainability front, rPET is produced from recycled plastic bottles, helping to cut energy use and carbon emissions compared to virgin polyester. Plus, it keeps plastic waste out of landfills. Cotton blends, however, typically require more water to produce and don’t offer the same eco-friendly benefits. While rPET uniforms might come with a slightly higher initial price tag, their durability and reduced need for frequent replacements often make them a more cost-effective choice for teams in the long run.