Sublimation printing has reshaped how team uniforms are made, offering vibrant, durable designs that bond directly with fabric. Unlike older methods, this process embeds ink into polyester at a molecular level, ensuring long-lasting colors that won’t fade, crack, or peel. Teams across sports like basketball, soccer, and baseball now enjoy fully customizable options, including names, numbers, and logos, without added costs.

Key takeaways:

- Limitless designs: Smooth gradients, full-color artwork, and even photorealistic images.

- Durability: Graphics stay intact after countless washes.

- Comfort: Uniforms remain breathable and lightweight.

- Eco-friendly options: Water-based inks and recyclable materials reduce waste.

With advancements in printer speed and resolution, teams can get high-quality uniforms faster than ever. Sublimation combines performance, personalization, and quality, making it a top choice for athletes and organizations alike.

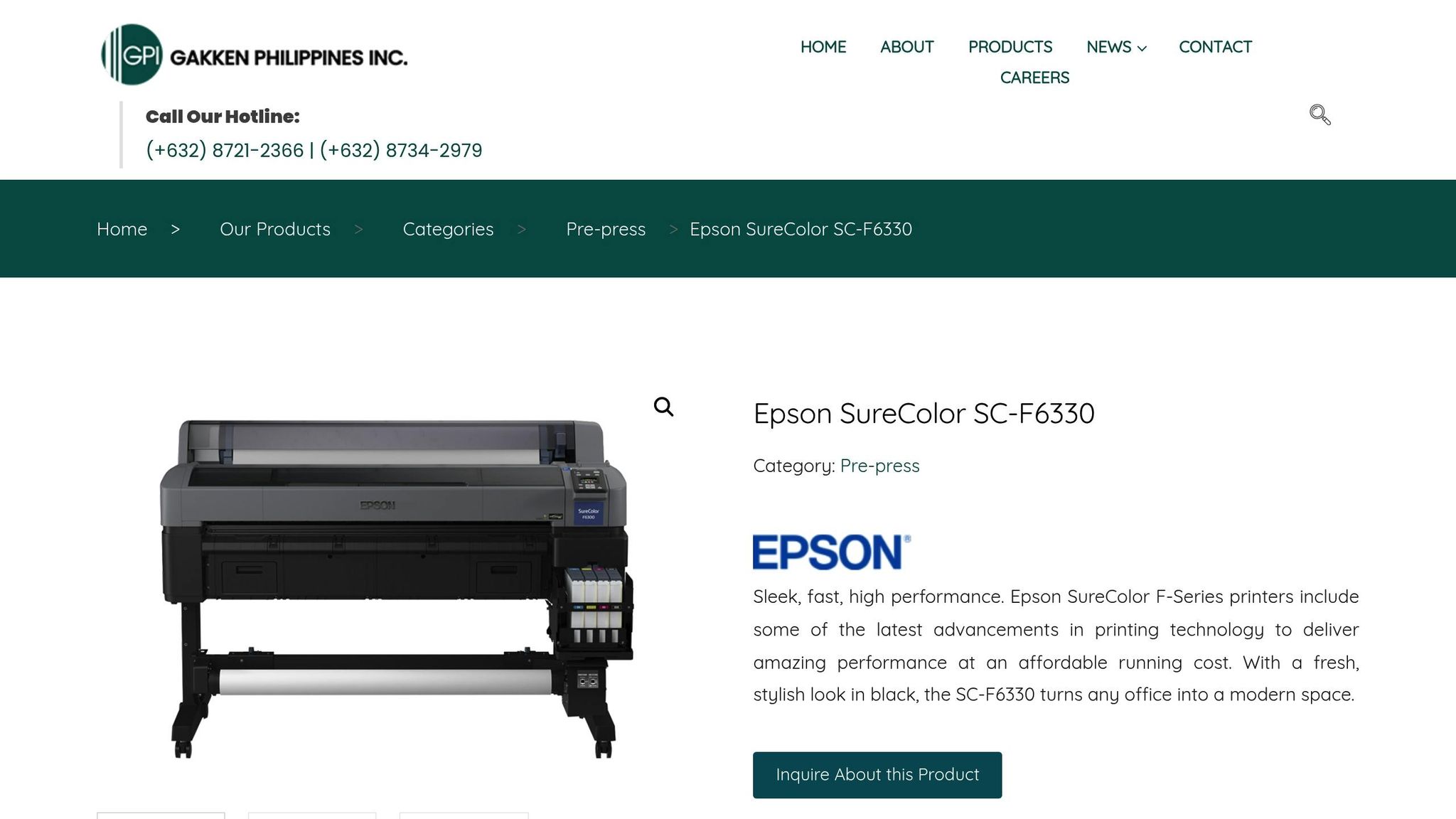

Sublimation Printing Jersey using Epson F6330 Dye Sublimation Printer

Key Advances in Sublimation Printer Technology

Recent developments in sublimation printing technology have taken the process to a whole new level, making it easier, faster, and more environmentally conscious to produce custom uniforms. These advancements not only enhance the quality of the final product but also cater to the growing demand for sustainable manufacturing practices.

Higher Resolution and Faster Printing

Today’s sublimation printers are designed to deliver stunning image quality and impressive speed. With resolutions reaching up to 1,440 dpi and the ability to print more than 1,000 square feet per hour, these printers ensure that custom uniforms can be produced in record time – often within days instead of weeks. This means teams can enjoy sharp, detailed designs, whether it’s for team names, numbers, or intricate mascots, even when working under tight deadlines. Such advancements pave the way for creating visually striking and high-performance uniforms.

Eco-Friendly Improvements

Sustainability has become a major focus in sublimation printing, with new technologies addressing environmental concerns without sacrificing quality. Modern printers now use water-based, non-toxic inks that significantly reduce harmful emissions while still delivering vibrant, long-lasting prints. These inks bond seamlessly with polyester fabrics, ensuring uniforms retain their color and durability even after numerous washes. Additionally, manufacturers have adopted recyclable and sustainably sourced transfer papers, cutting down on production waste.

Here’s a quick look at how eco-friendly sublimation methods compare to traditional ones:

| Feature | Traditional Sublimation | Advanced Eco-Friendly Sublimation |

|---|---|---|

| Ink Type | Chemical-based inks | Water-based, non-toxic inks |

| Environmental Impact | Higher emissions and waste | Reduced emissions, recyclable materials |

| Print Quality | High quality | Matches high quality |

| Durability | Fade-resistant | Equally fade-resistant |

| Production Speed | Standard speeds | Over 1,000 sq ft/hour |

These innovations have solidified sublimation printing as the go-to solution for teams looking for high-quality, sustainable, and quickly produced custom uniforms.

How Sublimation Improves Team Uniform Design

Sublimation printing has completely changed the game when it comes to designing team uniforms. It’s not just about sharper prints – it’s about opening up a world of creative possibilities, making customization easier, and ensuring uniforms stay durable over time. This technology has redefined how teams can represent themselves visually and practically.

Unlimited Design Options

One of the biggest advantages of sublimation printing is the freedom it offers. Unlike traditional screen printing, which limits you to basic designs and a handful of colors, sublimation allows for endless color combinations, smooth gradients, and intricate patterns that can cover the entire uniform. Teams can now include photographic images, detailed mascots, and complex designs that were once unimaginable.

Here’s how it works: sublimation embeds dye directly into polyester fabric, allowing for rich, vibrant colors without adding extra cost or complexity. This means teams can create standout designs like realistic flames, scenic backgrounds, or geometric patterns that simply aren’t possible with older methods.

"I came up with an idea of what I wanted and they made it happen." – Juan R.

This creative flexibility has led more sports teams, schools, and clubs across the United States to embrace sublimation over traditional printing. The ability to turn any design concept into reality has transformed how teams showcase their identity and build pride among players and fans alike.

Custom Names, Numbers, and Logos

Sublimation doesn’t just offer design freedom – it makes personalization effortless. Player names, numbers, and sponsor logos can all be added seamlessly at no extra cost once the design template is ready. Every uniform can be unique, yet the quality and consistency remain flawless across the entire order.

Traditional methods often involve separate steps for adding names and logos, which can drive up costs and lead to inconsistencies. With sublimation, everything – base design, names, numbers, and logos – is printed in a single, unified process. This ensures that every detail, no matter how small, is just as durable and vibrant as the rest of the uniform.

"Making them just how I wanted was easy, and the team did a great job paying attention to all the little details." – Olivia

This streamlined process is especially cost-effective for larger orders. Teams can finalize all customizations before production starts, making it easy to create professional-grade uniforms that fit both their vision and their budget.

Fade-Resistant Graphics for Long-Lasting Wear

Sublimation also stands out for its durability. The graphics don’t sit on top of the fabric – they’re infused into it. This means they won’t crack, peel, or fade, even after countless washes. The colors stay bold and vibrant, keeping uniforms looking sharp season after season.

Because the graphics are integrated into the fabric, there’s no added bulk or stiffness, and the material retains its natural stretch and comfort. Players can move freely and perform at their best, all while wearing uniforms that look as good as they feel.

"Our high quality sublimated uniforms are made to last so your players can look and feel their best." – Wooter Apparel

When compared to traditional printing methods, which often show wear and tear within a single season, sublimated uniforms are a clear winner. They maintain their appearance and performance over multiple seasons, making them a smart long-term investment for teams that value both quality and cost-efficiency.

To get the most out of sublimation, teams should start with high-resolution artwork and choose polyester-based fabrics. Partnering with experienced sublimation providers ensures that the final product not only looks great but also meets the demands of performance and durability. This combination of creativity, personalization, and longevity is why sublimation has become the go-to choice for serious athletic programs.

sbb-itb-4d95ad3

Practical Tips for High-Quality Sublimated Uniforms

Creating high-quality sublimated uniforms involves more than just printing designs on fabric. It requires careful attention to design preparation, fabric selection, and rigorous quality control. These steps ensure the final product stands out and meets the demands of both performance and aesthetics.

Design File Preparation

The foundation of great sublimated uniforms starts with properly prepared design files. Always use vector formats like .AI, .EPS, or .SVG for sharp, scalable designs. If you’re working with raster images, make sure they’re at least 300 DPI to prevent blurry or pixelated prints on the fabric.

Another often-overlooked detail is the color profile. Designs should use a CMYK color profile instead of RGB. Why? CMYK aligns with printing processes, ensuring the colors you see on your screen closely match the printed results. This is crucial for maintaining team colors or sponsor logos without unexpected shifts.

"The design team took my thoughts and created several perfect options for our swim team, using our logo created by one of our swimmers." – Tammy S., Customer

Organizing your design files is just as important. Keep elements on separate layers and provide both outlined and editable versions. This makes last-minute tweaks easier and ensures consistency across all pieces of the uniform. Once the design is ready, choosing the right fabric becomes the next key step.

Selecting the Right Fabrics

Fabric choice plays a huge role in the final quality of sublimated uniforms. Polyester or high-polyester blends work best, as they absorb dye effectively and produce vibrant, durable prints.

But it’s not just about looks – performance matters too. The ideal sublimation fabrics combine polyester’s print-friendly properties with moisture-wicking technology, keeping athletes dry and comfortable during games while maintaining bold colors and crisp graphics.

Breathability is another factor to consider. Modern polyester fabrics designed for sublimation allow for excellent airflow, ensuring athletes stay cool even during intense activity. This balance of function and appearance keeps uniforms looking sharp all season long.

"Great material." – Julie B., Verified Buyer

Fabric weight and stretch are also critical. Lightweight fabrics are perfect for sports requiring high mobility, while heavier materials provide structure for uniforms that need to hold their shape. Testing different options ensures you find the right balance for your team’s specific needs.

Quality Control Checks

After nailing the design and fabric selection, quality control ensures the uniforms meet expectations. Start by verifying color accuracy and design alignment. Compare printed samples to the approved design to confirm that every logo, number, and name is sharp, correctly positioned, and consistent across all uniforms.

Next, assess the construction quality. Check fabric integrity, seam strength, and the flexibility of sublimated graphics. Uniforms should not only look professional but also withstand the rigors of athletic performance.

"The uniforms are very well made and of great quality." – Jason P., Verified Buyer

Sizing consistency is equally important. Review each uniform against the approved sizing charts to prevent fit issues that could impact player performance or the team’s overall appearance. Prototype testing helps fine-tune the fit, design, and overall quality before full production begins.

Finally, proper care is essential to maintain quality after production. Washing uniforms in cold water, avoiding bleach and fabric softeners, and tumble-drying on low can help preserve both the fabric and color vibrancy throughout the season.

Spotlight: Wooter Apparel‘s Approach to Sublimated Team Uniforms

Wooter Apparel has embraced advanced printing technologies to redefine team uniform design. They specialize in fully sublimated uniforms that combine cutting-edge printing techniques with high-quality materials. With over 2,000 five-star reviews and an impressive 4.9-star rating from 1,238 reviews, Wooter Apparel showcases how sublimation can revolutionize team uniforms across various sports.

Custom Products and Services

Wooter Apparel provides a wide range of sublimated products for sports like basketball, football, baseball, softball, and soccer. Their offerings include jerseys starting at $16.99, shorts, warmup gear, and accessories. One standout feature is their free custom design service, which allows teams to craft uniforms that truly reflect their identity – without any additional design fees. This approach makes professional-grade custom uniforms accessible to organizations with different budget sizes.

Their product lineup ranges from individual items to all-inclusive packages, like the Custom Basketball Team Uniform Package – MVP ($199.99). This package includes jerseys, shorts, and warmups, offering a complete solution for teams looking for both style and functionality.

Blending Performance and Style

Wooter Apparel’s sublimation process ensures that their uniforms are as functional as they are visually striking. Unlike traditional printing methods that can result in bulky, heat-trapping designs, their sublimation technique embeds the graphics directly into the fabric. This preserves the material’s natural qualities, ensuring a lightweight, breathable fit while delivering vibrant, durable designs. The result? Uniforms that balance comfort, performance, and bold aesthetics, keeping athletes cool and unrestricted during high-intensity games.

Speedy Delivery and Customer Satisfaction

Beyond the quality of their products, Wooter Apparel has built a reputation for outstanding service and fast delivery. Many customers report receiving their orders ahead of schedule, a crucial factor for teams working with tight deadlines.

Customer reviews frequently highlight their efficient service. For example, Derrick M. shared how his jerseys arrived a week early, while Mark W. praised the company’s clear and consistent communication throughout the process.

Conclusion

Sublimation printing has revolutionized uniform design, offering teams the chance to bring their most creative ideas to life while meeting the high-performance demands of athletes. By infusing bold, fade-resistant graphics directly into the fabric, this method ensures designs that not only stand out but also endure.

With the ability to showcase intricate logos, gradients, and full-color artwork, sublimation goes far beyond the limits of traditional printing methods. And the best part? The finished uniforms remain lightweight and breathable, keeping athletes comfortable even during the most intense moments on the field or court. It’s a perfect blend of striking design and practical functionality.

Wooter Apparel exemplifies how advanced sublimation techniques can deliver real benefits. By combining cutting-edge printing methods with a focus on usability, they prove that premium sublimated uniforms can be both dependable and accessible.

Whether for youth leagues or elite competitive teams, sublimation printing offers a winning combination of durability, performance, and standout visuals. Teams no longer need to compromise – this technology ensures they get the best of both worlds in every uniform.

FAQs

How does sublimation printing make team uniforms more durable and long-lasting compared to other methods?

Sublimation printing takes team uniforms to the next level by embedding designs directly into the fabric. Unlike older methods where designs sit on the surface, this approach creates a lasting bond that won’t crack, peel, or fade over time.

With this method, colors remain vibrant, and designs stay sharp, even after countless washes and the wear-and-tear of intense gameplay. It’s an ideal choice for producing durable, high-performance uniforms that look as good as they perform.

What are the environmental advantages of using eco-friendly sublimation printing for team uniforms?

Eco-friendly sublimation printing stands out as a greener alternative for producing custom team uniforms. Unlike traditional printing methods, this technique relies on water-based inks that are free of harmful chemicals. Plus, it generates far less waste. Another key advantage? It skips the excessive use of water and energy, making it a cleaner and more efficient option.

With this approach, teams get bold, durable designs while making a conscious effort to minimize their impact on the planet. It’s a smart choice that benefits both performance and the environment.

What’s the best way to prepare design files for sublimation printing on team uniforms?

To get the best results with sublimation printing, it’s crucial to prepare your design files correctly. Start by ensuring your files are high resolution – at least 300 DPI – for sharp and detailed prints. For the cleanest designs, use vector formats like AI, EPS, or PDF. Also, make sure your colors are set to CMYK to align perfectly with the printing process.

If you’re working with Wooter Apparel, you’re in good hands. Their team provides free custom design services and expert support to help you create fully sublimated uniforms that blend performance with style. By properly prepping your files and teaming up with their designers, your uniforms will make a statement both on and off the field.