Testing aerodynamics in sports apparel is all about reducing drag and improving performance. This involves analyzing how air flows around an athlete’s body and clothing using tools like wind tunnels, airflow sensors, and advanced measurement devices. The process focuses on fabric selection, fit, seam placement, and garment design to optimize airflow and minimize resistance. Here’s a quick breakdown:

- Fabric Matters: Smooth, synthetic materials reduce drag better than rough or natural fibers.

- Fit is Key: Tight but non-restrictive fits prevent air pockets that increase resistance.

- Seam Placement: Flat-lock or seamless designs minimize airflow disruption.

- Surface Treatments: Textures or coatings can enhance aerodynamic properties.

- Testing Tools: Wind tunnels, anemometers, and flow visualization techniques help refine designs.

The process begins with fabric analysis, progresses to prototype testing in controlled environments, and ends with real-world evaluations. By combining aerodynamic science with athlete feedback, designers create gear that balances performance, comfort, and durability. For teams, investing in aerodynamic testing can lead to measurable gains in speed and efficiency.

Custom Aerodynamics – Bioracer meets AirShaper

Tools and Methods for Aerodynamic Testing

Testing aerodynamic properties requires specialized tools and controlled environments to gather precise data. These tools help uncover how air flows around an athlete’s body and pinpoint areas where drag can be reduced. In professional sports apparel testing, traditional wind tunnel methods are often paired with modern sensor technology to provide a comprehensive view of aerodynamic performance. Let’s break down the key methods used to collect this data.

Wind Tunnels and Controlled Environments

Wind tunnels are the go-to choice for aerodynamic testing because they create consistent, repeatable conditions. By using fans to generate steady airflow, they eliminate variables like shifting wind directions, temperature changes, or atmospheric pressure – factors that can complicate outdoor testing.

Testing in a wind tunnel involves positioning athletes (or mannequins) in sport-specific postures. For example, a cyclist might be placed in an aerodynamic tuck, a runner in mid-stride, or a soccer player in a sprinting pose. This setup allows testers to collect accurate data on drag, lift, and side forces. While mannequins are sometimes used when human subjects aren’t available, they can’t replicate the subtle body movements that occur during real competition.

Wind tunnel balances are critical for measuring forces in these environments. Advanced six-axis force torque sensors can track drag, lift, and side forces in real time. For instance, systems like the Hypersen HPS-FT120 can measure forces with an accuracy of 1.5 N under loads as high as 4,000 N. However, wind tunnel testing isn’t without its challenges. Achieving the precision needed for small performance gains – like a 1% improvement – requires reducing drag by 5-10%, yet maintaining repeatability better than 1% in wind tunnels can be difficult. Despite these challenges, the data collected is crucial for refining designs in later stages.

Measurement Devices for Data Collection

Modern aerodynamic testing relies on an array of measurement tools, each playing a distinct role in understanding how air interacts with both the athlete and their apparel.

- Hotwire anemometers are ideal for measuring localized airflow speeds over textiles and specific garment areas. These are calibrated against tools like vane anemometers for accuracy.

- Flow visualization techniques, such as fluorescent dyes and smoke trails, offer a visual representation of airflow patterns. These methods highlight turbulence and areas where airflow separates around the uniform.

- Pressure taps and pressure rakes map pressure distribution around the subject, pinpointing areas where flow separation occurs.

For testing outside the lab, portable aerodynamic systems like Aerosensor provide real-time data during actual athletic activity. These systems combine inputs such as speed, power, altitude, and wind data to calculate the aerodynamic drag coefficient (CdA) on the fly, bridging the gap between controlled environments and real-world conditions.

Prototyping and Fabric Screening

The process often begins with fabric screening and prototype evaluation to identify the best materials and designs before full-scale wind tunnel testing.

Fabric screening involves testing individual materials under controlled airflow. Using tools like adapted linear tribometers, researchers can measure the aerodynamic drag of moving fabric samples in stationary air. This offers a cost-effective way to compare different materials early in the process.

Prototyping allows designers to test garment concepts before committing to full production. Early prototypes don’t need to be perfectly constructed – they just need to reflect the key design elements that affect aerodynamics. For example, basic versions can be sewn together quickly to test fit, seam placement, and overall garment shape.

At Wooter Apparel, this step-by-step approach ensures that custom uniform designs are both functional and aerodynamic. Initial fabric testing helps us choose the best materials for each sport, while prototype testing allows us to refine designs for maximum performance. Testing multiple variations – such as different sleeve lengths, collar styles, or hem treatments – can reveal how small adjustments affect airflow. By systematically fine-tuning these details, we create uniforms that not only perform well but also give teams a competitive edge. These refined prototypes then serve as the foundation for more detailed aerodynamic testing.

Step-by-Step Guide to Conducting Aerodynamic Tests

Here’s how to measure the aerodynamics of sports apparel effectively, starting from material selection and ending with full-scale wind tunnel testing.

Step 1: Initial Fabric Analysis

Start by analyzing individual fabric samples before testing entire garments. This early step helps identify the best materials, saving time and effort down the line.

Secure fabric samples on a standard frame within a controlled airflow system. Make sure all samples are the same size to maintain consistency in your data.

Test each fabric’s performance across different wind speeds, noting how airflow resistance changes. Pay close attention to how fabric weaves and textures react to these variations.

Additionally, test fabrics under both dry and lightly misted conditions. Since sweat can affect a fabric’s aerodynamic properties, this comparison highlights how performance shifts between dry and moist environments.

Step 2: Wind Tunnel Testing

Once you’ve pinpointed high-performing materials, move on to wind tunnel testing with complete garments. This stage requires precise setup and detailed data collection.

Position your test subject – whether it’s an athlete or a mannequin – in a sport-specific posture. For instance, a cyclist might adopt a tucked position, while a runner could be placed mid-stride.

Gradually increase wind speeds, allowing stabilization at each interval, and record aerodynamic forces like drag, lift, and side forces using calibrated sensors.

To better understand airflow patterns, use tools like smoke trails or fluorescent dyes. Focus on areas prone to turbulence, such as seams, fabric transitions, and spots where the garment doesn’t fit snugly.

Test multiple garment configurations by tweaking elements like sleeve lengths, collar designs, and overall fit. For example, Wooter Apparel evaluates several design variations in a single session, maximizing the insights gained from each test.

Step 3: Data Analysis and Iteration

With the wind tunnel data in hand, it’s time to analyze and refine your designs.

Calculate the drag coefficient (Cd = 2F/(ρAV²)) for each configuration. Plot these values across the range of tested speeds to identify trends and pinpoint optimal conditions.

Compare the aerodynamic performance of different design variations. In competitive sports, even small reductions in drag can translate to meaningful performance improvements. Identify which design elements contribute most to reducing drag.

Examine flow separation patterns revealed during testing to locate areas where airflow detaches and creates turbulence. Use this information to prioritize design changes. For instance, repositioning seams or altering fabric transitions can often yield significant aerodynamic benefits with minimal effort.

Plan additional testing cycles based on your findings. Refining aerodynamic performance typically requires multiple iterations. At Wooter Apparel, this approach ensures every design not only improves performance but also maintains durability and comfort.

Finally, document all test results and design changes – successful or not. A detailed record helps avoid repeating ineffective methods and supports ongoing improvements.

sbb-itb-4d95ad3

Reading Results and Making Design Changes

Turn aerodynamic test data into actionable design improvements by interpreting measurements and weighing performance trade-offs.

Understanding Drag Coefficient Data

Using wind tunnel data, evaluate drag coefficient (Cd) values to inform design adjustments. The drag coefficient is a numerical measure of how much resistance an object encounters as it moves through air. Lower Cd values mean less air resistance and better aerodynamic performance. For instance, a streamlined uniform will have a lower Cd compared to one with bulky or protruding features. To illustrate, a teardrop-shaped object can achieve a Cd as low as 0.05, highlighting the potential for optimization.

Pinpoint design elements that contribute to drag by analyzing factors like skin friction and form drag. Understanding which factor plays a larger role helps prioritize design tweaks effectively.

Look for consistent Cd patterns across varying wind speeds. If Cd values fluctuate at higher speeds, it could indicate flow separation, signaling areas for improvement.

Additionally, comparing fabric types and garment configurations can uncover small but meaningful performance gains. Take cycling as an example: at speeds of around 31 mph, aerodynamic resistance accounts for nearly 90% of the total power output.

Once Cd values are understood, the focus shifts to balancing aerodynamic improvements with other performance needs.

Balancing Aerodynamics with Other Factors

Enhancing aerodynamics is essential, but it shouldn’t come at the expense of overall athletic performance. Uniforms need to reduce air resistance while maintaining comfort and mobility. For example, a snug fit might lower drag, but it’s equally important to ensure it doesn’t restrict the range of motion required for specific sports.

These design adjustments should align with the rigorous prototyping and testing phases already covered. At Wooter Apparel, we incorporate these considerations into every step of our process to ensure our uniforms excel in both aerodynamics and the practical needs of athletes.

The next step is presenting these findings in a way that’s clear and actionable.

Presenting Test Results

Effectively displaying aerodynamic test data helps stakeholders understand performance improvements and make informed decisions. Use summary tables to capture key details like test configurations, drag coefficients, wind speeds, and percentage improvements. For example:

| Test Configuration | Drag Coefficient (Cd) | Wind Speed (mph) | Improvement vs. Baseline | Notes |

|---|---|---|---|---|

| Baseline Design | 0.65 | 25 | – | Standard team uniform |

| Modified Seams | 0.58 | 25 | 10.8% | Relocated shoulder seams |

| Fabric Upgrade | 0.52 | 25 | 20.0% | Smooth-surface material used |

| Combined Changes | 0.48 | 25 | 26.2% | All modifications applied |

Documenting test conditions – such as wind tunnel settings, equipment calibration, and subject positioning – ensures the data is reliable and comparisons are valid.

Translate these aerodynamic improvements into practical benefits. For example, reduced drag coefficients can mean energy savings and better performance. In downhill skiing, switching to a more streamlined posture can result in speed gains of nearly 12% over just a 2-second interval.

Visual aids, like smoke trail photos or flow visualization images, can further clarify why certain design changes work. Finally, prioritize recommendations based on their impact versus the effort required, ensuring the most effective changes deliver the greatest performance advantages.

Best Practices for Custom Team Uniforms

Building on aerodynamic testing insights, refined uniform practices can significantly boost athletic performance. The best uniforms combine scientific research with sport-specific design, leading to measurable improvements.

Importance of Fit and Customization

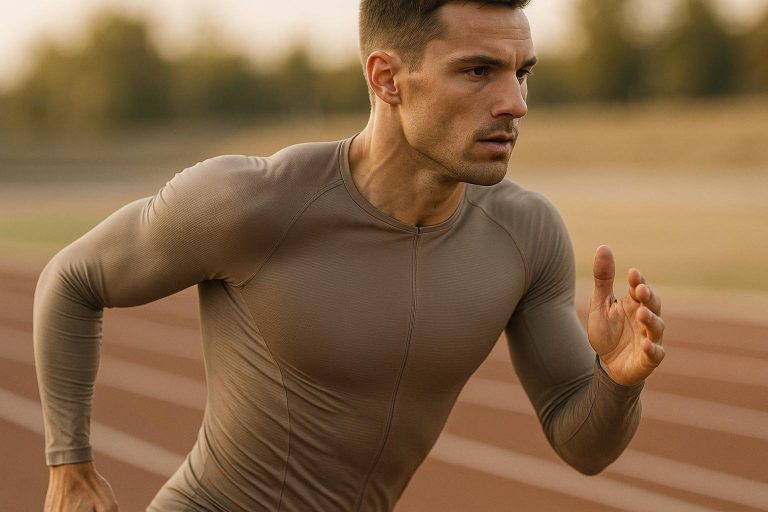

When it comes to custom team uniforms, a precise fit is more than just a matter of appearance – it’s a performance game-changer. A well-fitted uniform reduces drag, a critical factor in high-speed sports where air resistance can heavily impact results. By improving aerodynamic efficiency, these optimized uniforms can save valuable time during competition.

The secret lies in tailoring uniforms to fit snugly against the body while eliminating loose or flapping fabric. This requires considering each athlete’s unique posture and movement patterns during their sport. For instance, designs that account for an athlete’s racing stance can minimize wrinkles and air pockets, which could otherwise disrupt airflow. A uniform that fits perfectly while standing may fail to perform when the athlete is in motion, so sport-specific tailoring is key.

Strategic fabric placement further enhances performance. Textured materials on limbs and smooth fabrics on the torso can guide airflow more effectively, as different body parts interact with air in distinct ways.

However, performance shouldn’t come at the expense of comfort and mobility. Ill-fitting or uncomfortable uniforms can restrict movement and negatively impact an athlete’s performance. The most effective designs strike a balance, using breathable, stretchable, and lightweight materials that support an athlete’s range of motion while maintaining aerodynamic properties. Each design iteration should undergo rigorous testing to ensure it meets the demands of the sport.

Reliable Testing Protocols

Reliable testing is the backbone of effective uniform design. Combining wind tunnel testing with real-world athlete feedback ensures the final product performs as intended. Wind tunnel testing, often considered the gold standard, provides precise data on drag reduction. However, these tests must follow strict protocols, including consistent conditions, calibrated equipment, and standardized athlete positioning for accurate results.

In-Home Usage Tests (IHUTs) complement lab testing by evaluating how uniforms perform during actual athletic activities. These real-world tests often uncover issues that controlled environments miss. To get the most accurate feedback, it’s essential to involve athletes who closely match the demographic profile of the intended users.

Testing should address both objective data, like drag coefficients, and subjective athlete feedback on comfort, mobility, and durability. This dual approach ensures a comprehensive understanding of the uniform’s performance. For example, while wind tunnel data might highlight aerodynamic efficiency, athlete feedback can reveal whether the uniform feels restrictive or uncomfortable during specific movements.

A structured testing framework is crucial. It should include clear objectives, such as evaluating comfort during various activities, durability over time, or fit preferences. Athlete feedback can be collected through detailed questionnaires that cover key areas like initial impressions, comfort, moisture-wicking performance, stretchability, durability, and even style preferences.

Working with Expert Solutions

Once testing validates the design, collaborating with experienced manufacturers is the next step in bringing these advancements to life. Expert manufacturers combine aerodynamic principles with precise production techniques to create high-performance uniforms.

At Wooter Apparel, aerodynamic science is embedded in every stage of the design process. Fully sublimated designs allow for precise fabric placement and seamless construction, ensuring that performance-enhancing features don’t compromise durability or appearance over time.

Advanced manufacturing methods make it possible to include features that traditional techniques can’t achieve. For example, laser-cut sleeves and minimal seams reduce air turbulence, while seamless fabric transitions avoid the bulkiness of conventional sewing. This precision allows for the integration of multiple fabric types and textures in specific areas, optimizing airflow management.

Customization options also go far beyond basic personalization. Player names, numbers, sleeve lengths, and collar styles can all be tailored to individual preferences without sacrificing aerodynamic performance. This ensures that each athlete gets a uniform designed for their unique needs, while still meeting the team’s overall performance goals.

Partnering with expert manufacturers also provides access to cutting-edge fabric technologies and testing capabilities. Through iterative testing and refinement, teams can achieve the perfect balance of performance, comfort, durability, and style. This collaborative approach ensures that the final uniforms not only meet practical requirements but also deliver measurable advantages on the field or track.

Conclusion

Aerodynamic testing brings science and performance together, proving that even small tweaks in fabric and fit can translate into measurable advantages. These seemingly minor changes often make the critical difference between winning and losing.

Key Takeaways

Aerodynamic testing starts with analyzing fabric and extends to wind tunnel experiments, ensuring every design choice enhances airflow. The most effective protocols combine controlled lab conditions with feedback from athletes in action. This ensures that theoretical gains actually deliver results on the field or track.

Customization sets exceptional uniforms apart from average ones. Standard sizes and generic fits simply can’t match the aerodynamic efficiency of designs tailored to specific sports and individual athletes. Testing repeatedly shows that a uniform’s performance hinges on how it moves with the athlete, not just how it looks when stationary.

While the tools for aerodynamic testing have advanced over time, the core idea remains the same: measuring leads to improving. Wind tunnels provide the precision needed for drag coefficient calculations, while advanced sensors detect subtle differences that separate winning designs from the rest.

However, performance isn’t the only factor. Comfort, durability, and team identity also matter. The best testing protocols evaluate how aerodynamic tweaks impact moisture control, flexibility, and long-term wear. These insights guide smarter designs that boost both performance and overall athlete satisfaction.

Next Steps for Teams

To maximize performance, teams should integrate aerodynamic testing into the uniform selection process from the start – not as an afterthought. This involves collaborating with manufacturers who understand both the science of aerodynamics and the practical demands of competitive sports.

Each sport has unique aerodynamic challenges. For example, cycling and speed skating deal with entirely different airflow patterns than swimming or track and field. By tailoring testing efforts to these specific needs, teams can focus on changes that deliver the most impact.

Partnering with manufacturers who provide full testing capabilities and custom solutions is another smart move. Companies like Wooter Apparel blend aerodynamic principles with advanced production techniques, offering fully sublimated uniforms that balance performance, durability, and visual appeal. Their process highlights how modern designs can elevate both team identity and athletic performance.

Investing in aerodynamic testing pays off in more ways than just faster race times or improved stats. Athletes often feel more confident and perform more consistently when they know their gear is optimized to give them every possible edge.

The future of sports apparel lies in merging scientific precision with practical design. Teams that embrace aerodynamic testing today position themselves as leaders in athletic performance, where even the smallest gains can crown champions.

FAQs

How does fabric choice affect the aerodynamics of sports uniforms?

The fabric in sports uniforms isn’t just about style – it’s a game-changer for performance. Smooth, tightly woven materials are key to improving aerodynamics, as they reduce surface friction and allow air to flow more smoothly over the body. This can make a noticeable difference in speed and efficiency, especially in high-intensity sports where every fraction of a second counts.

On top of that, fabrics with advanced features like moisture-wicking or quick-drying properties not only keep athletes comfortable but can also reduce drag, helping them stay focused on their game. Simply put, the right fabric can be the difference between good performance and peak performance.

How are wind tunnels used to test the aerodynamics of sports uniforms, and how reliable are the results?

Wind tunnels play a key role in assessing the aerodynamics of sports uniforms. By simulating controlled airflow around an athlete or their gear, they help analyze elements like fabric behavior, drag reduction, and body positioning – all crucial for improving athletic performance.

These tests provide accurate measurements of aerodynamic forces, making them a dependable tool in sports science. However, factors like the size of the test model and specific environmental conditions can affect results. Even with these challenges, wind tunnel testing continues to be one of the most reliable methods for designing high-performance sportswear.

How can teams test the aerodynamics of their uniforms to boost performance?

Teams have a couple of powerful tools at their disposal when it comes to testing the aerodynamics of their uniforms: wind tunnels and computational fluid dynamics (CFD) simulations. These methods let them study how various fabrics, cuts, and designs interact with airflow and impact drag around the athlete.

By experimenting with prototype uniforms, teams can collect detailed data on how well each design performs aerodynamically. This helps them choose options that cut down on air resistance, boost speed, and ultimately improve an athlete’s performance on the field or track.