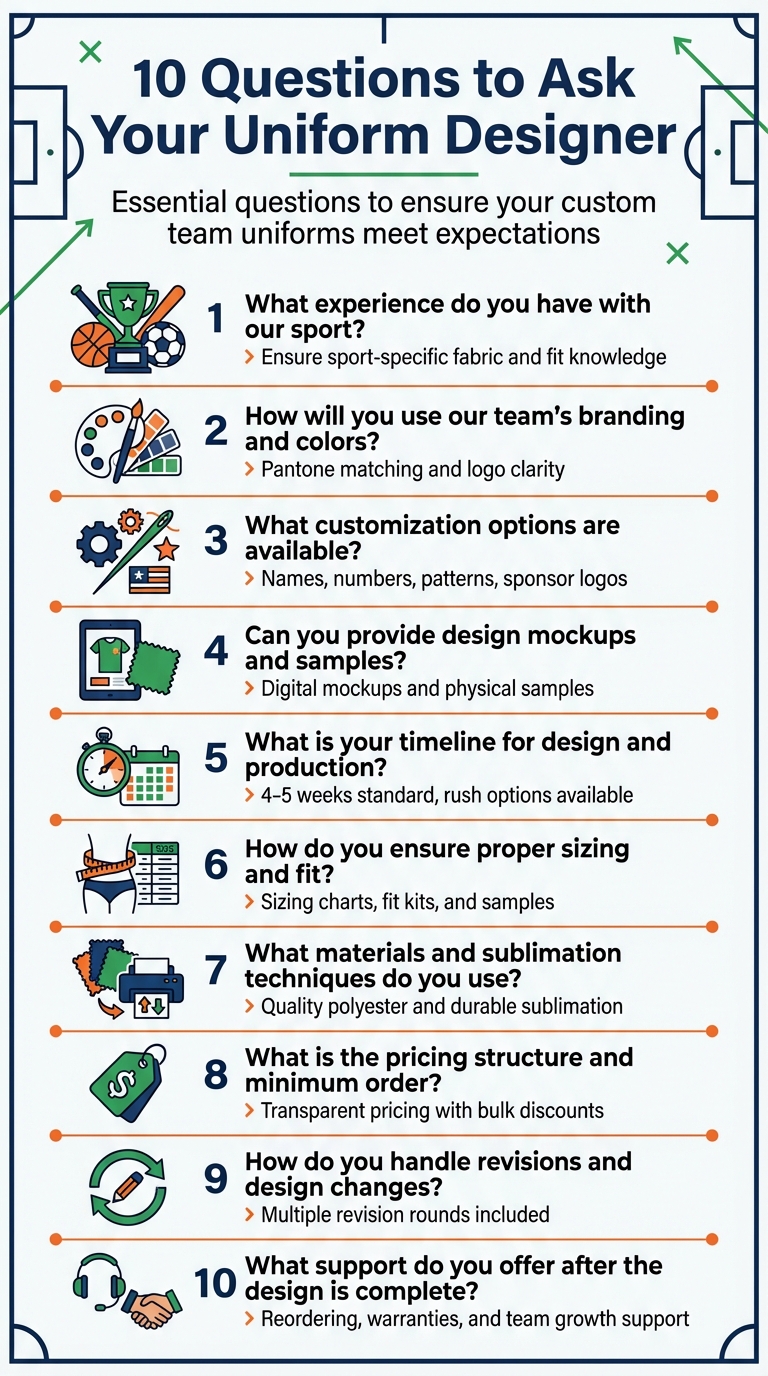

Creating custom team uniforms is more than just picking colors and adding logos. To ensure the final product meets your expectations, you need to ask the right questions upfront. This helps avoid delays, sizing issues, or design mistakes. Here’s a quick overview of the 10 key questions to guide your discussions with a uniform designer:

- What experience do you have with our sport?

Designers with sport-specific knowledge understand fabric needs, fit, and performance requirements. - How will you use our team’s branding and colors?

Ask about Pantone color matching and ensuring logos are clear and accurate. - What customization options are available?

Explore options like player names, numbers, patterns, and sponsor logos. - Can you provide design mockups and samples?

Request digital mockups and physical samples to confirm quality and accuracy. - What is your timeline for design and production?

Understand how long each stage takes and if rush production is an option. - How do you ensure proper sizing and fit?

Use sizing charts, fit kits, and samples to avoid errors. - What materials and sublimation techniques do you use?

Look for high-quality polyester fabrics and durable sublimation printing. - What is the pricing structure and minimum order?

Clarify costs, including design fees, shipping, and minimum order quantities. - How do you handle revisions and design changes?

Confirm the number of revisions allowed and how feedback is incorporated. - What support do you offer after the design is complete?

Ask about reordering, warranties, and adding new team members.

10 Essential Questions to Ask Your Custom Uniform Designer

Different Types of Materials , Styles , and Methods used to Customize Jerseys

1. What Experience Do You Have with Our Sport?

When designing sports uniforms, understanding the unique needs of each sport is crucial. For example, basketball jerseys must allow for unrestricted overhead movement, while football uniforms have to withstand constant physical contact. A designer with experience in your specific sport will already be familiar with these demands. They’ll know which fabrics perform best, how the fit should adapt to intense activity, and how to balance functionality with compliance to regulations. This knowledge helps ensure every design decision is purposeful and effective.

Sport-Specific Requirements

Each sport comes with its own set of performance needs. Basketball uniforms often use interlock mesh fabric for durability, paired with lycra around the neck and shoulders to provide flexibility for shooting and defensive maneuvers. Baseball and softball uniforms, on the other hand, must endure sliding and heavy wear, requiring reinforced stitching and fabric weights ranging from 140 to 280 GSM depending on the level of play. Soccer kits focus on being lightweight and moisture-wicking, helping players stay comfortable and agile throughout a 90-minute match.

At Wooter Apparel, the design team has years of experience creating uniforms for basketball, football, volleyball, soccer, and baseball. They apply the same professional standards to local teams as they do to elite organizations. By staying up to date with current sportswear trends and using advanced sublimation techniques, they ensure graphics remain vibrant and intact – even after numerous washes.

Request Examples of Past Work

To confirm a designer’s skill, ask for a portfolio that highlights their experience with your specific sport. For instance, Alex A. successfully delivered custom uniforms to 120 basketball players within a 3-week timeframe in October 2017, earning praise for the uniforms’ comfort. Similarly, Calix C. ordered volleyball uniforms in October 2018 and commended the outstanding color accuracy and fast delivery.

"Our designers are experienced professionals who are always working to create unique designs for sports teams all over the world." – Wooter Apparel

When reviewing past projects, focus on details like logo placement for visibility during gameplay, the vibrancy of colors in action shots, and whether player numbers are integrated seamlessly into the overall design. These elements reflect both technical expertise and attention to detail.

2. How Will You Use Our Team’s Branding and Colors?

Your team’s identity shines through every small detail, from the colors on your jerseys to the placement of your logo. A skilled designer treats these elements with the same attention to detail you’ve invested in building your team’s reputation. This means using reliable systems to ensure the design you approve on a mockup translates perfectly to the final product. It’s all about nailing the essentials like accurate color matching and logo clarity.

Color Matching and Logo Placement

Getting colors right isn’t as simple as picking a shade from a palette. Professional designers rely on the Pantone Matching System (PMS), a globally recognized standard for precise color reproduction. With over 200 shades of orange alone, saying “orange” isn’t enough – you need the exact Pantone code to guarantee consistency. By sharing your team’s specific Pantone values, you ensure that your colors stay uniform across all materials, whether it’s jerseys, banners, or merchandise.

"Pantone is a global standard that ensures we’re all speaking the same language when we talk about color, allowing us to do a better job of producing the colors that you ordered." – Wooter Apparel

When it comes to logos, vector files like .ai or .pdf are the gold standard. These files use mathematical formulas to keep your logo crisp and clear, no matter the size. If your logo exists only as a low-resolution image, consider asking about logo redrawing services. At Wooter Apparel, for example, sublimation printing is used to create vibrant, long-lasting colors that won’t fade or peel, ensuring your team looks sharp season after season.

Custom Design Elements

Personalized touches like patterns, mascots, or slogans help solidify your team’s visual identity. A good designer will also focus on practical details, such as ensuring names and numbers are easy to read during fast-paced action. You’ll also have the opportunity to specify the placement of sponsor logos, team emblems, and other branding features using mockup templates. This collaborative process ensures that the final design not only looks great but also reflects your team’s values and style.

3. What Customization Options Are Available?

When it comes to creating a unified team identity, understanding your customization options is key. The right approach allows you to fine-tune every detail – from fonts to patterns and graphics – so your uniforms truly represent your team. This level of personalization ensures a cohesive look across all apparel.

Design Features and Options

Thanks to modern sublimation printing, the possibilities for customization are almost endless. This method allows for seamless designs that can include everything from team slogans and sponsor logos to custom player names and numbers. Unlike older printing techniques that charge extra for each color or placement, sublimation fuses ink directly into polyester fabric, resulting in durable, crack-free designs.

"Every inch of the uniforms is fully customizable, exactly how you want." – Wooter Apparel

Player names and numbers are often included in the base pricing. For those wanting a different texture or style, premium options like tackle twill, embroidery, and sublimated patches are available. Reversible jerseys, which offer two designs in one, start at $24.99.

Matching Apparel and Accessories

Customization doesn’t stop with jerseys. You can extend your design to warmup sets, tracksuits, hoodies, and other team gear. By using consistent design files with identical Pantone colors and logos, you can ensure a flawless match across all items, avoiding any color discrepancies. Warmup sets typically start at $54.99, while custom tracksuit packages begin at $56.99 for bulk orders.

Most of this gear is made using the same sublimation process as the jerseys, guaranteeing perfect color coordination. The exception is items like socks, which are usually knitted for comfort and performance. Plus, with design files kept on record, you can easily reorder for new team members or expand your collection in future seasons.

4. Can You Provide Design Mockups and Samples?

Once you’ve nailed down the details of your sport-specific needs and customizations, it’s time to confirm the final design. This is where mockups and samples come into play. They help ensure your vision translates perfectly into the finished product. A reliable designer will provide digital mockups and physical samples to double-check design specifics, spot any errors, and verify color accuracy before production begins.

Free Design Mockup Services

Wooter Apparel offers a free custom uniform design service. Their in-house graphics team takes your ideas, sketches, or design briefs and turns them into professional mockups. Typically, these mockups are ready within 1 to 3 business days, depending on the complexity of the design.

"Our in-house graphics department will be at your disposal to create something never seen before! There is no fee for our custom uniform design service." – Wooter Apparel

To ensure the best print quality, submit your logos in vector formats like SVG, AI, EPS, PDF, or CDR at 300dpi. This avoids additional fees for redrawing artwork. Prefer to handle the design yourself? You can download vector-based templates (AI, EPS, or CDR formats), customize them, and send the finalized files for production.

Once the mockups are approved, the process moves smoothly into the next stage: ordering and reviewing physical samples.

Sample Ordering and Revision Process

Physical samples are a must for checking how your design looks in real life, including colors, materials, and overall quality. For large orders, Wooter Apparel includes free custom samples and sizing sets as part of their quality assurance process. This ensures everything meets your expectations before mass production begins. For smaller orders, custom samples are available for purchase.

"We encourage our clients to order a custom sample of their designed uniform to inspect the overall look and that it is to their expectation." – Wooter Apparel

This step is especially important because custom orders become non-refundable once production starts. Colors can sometimes appear slightly different on fabric compared to a screen due to factors like fabric weight. Ordering a physical sample helps you avoid costly mistakes. Plus, Wooter’s free design service includes revisions and color adjustments upon request, giving you the flexibility to perfect your design before moving forward.

5. What Is Your Timeline for Design and Production?

Timing is everything when it comes to getting your team outfitted. Knowing exactly when your uniforms will arrive makes it easier to hit your deadlines and avoid those last-minute headaches. A clear timeline helps you map out every stage of the process – from design to delivery – so your gear gets to you right when you need it.

Expected Timeline for Each Stage

Creating custom uniforms involves several distinct steps, each with its own timeframe. At Wooter Apparel, the design collaboration phase usually takes 1 to 3 business days, depending on the complexity of your design brief. Once the design is approved, sizes are confirmed, and payment is made, production takes around 20 to 25 business days. After production, shipping typically takes about 3 business days.

"Our turnaround is 2-4 weeks, and we are proud to make some of the highest quality uniforms, using only the most innovative fabrics in the market." – Wooter Apparel

From start to finish, the entire process – from order confirmation to delivery – averages 4 to 5 weeks. It’s important to note that the clock starts ticking only after your design, sizes, and payment are finalized. Handling all three simultaneously can help you avoid unnecessary delays.

Meeting Tight Deadlines

Need your uniforms sooner than the standard timeline? Wooter Apparel offers a rush production option, cutting the timeline down to 15 to 18 business days for an additional fee of $350 or 20% of the total order value, whichever is greater. If you have an urgent deadline, be sure to mention it in your design brief so your order gets prioritized. Wooter Apparel also backs its delivery commitments with a guarantee: if your order isn’t delivered within one month, you’ll receive a partial refund. For rush orders, if delivery takes longer than 15 business days, the rush fee will be refunded.

Here’s an example of how Wooter Apparel delivers under pressure: In December 2025, customer Derrick M. worked with Wooter representative Olga to get jerseys ready for a January 20th game. Despite starting the process on December 12th – right in the middle of the holiday season – the jerseys arrived a full week ahead of schedule. Similarly, in October 2017, Kenny C. received team reversibles for a tournament within the same week of placing his order.

sbb-itb-4d95ad3

6. How Do You Ensure Proper Sizing and Fit?

Getting the right fit is essential for both comfort and performance. Since custom uniforms can’t be returned or exchanged once they’re made, it’s smart to clarify sizing tools and processes with your designer from the start. This can help you avoid costly mistakes.

Sizing Charts and Fit Kits

To minimize fit issues, rely on accurate sizing tools and practices. Designers typically provide charts based on finished garment measurements, not body measurements. This approach ensures a more predictable fit compared to simply guessing based on existing gear. For example, Wooter Apparel offers detailed sizing charts tailored for youth, men’s, and women’s cuts across various sports.

Another effective solution is requesting physical sizing kits. These kits allow team members to try on samples before placing the final order. Wooter Apparel provides sport-specific sizing kits for baseball, football, volleyball, and more. For larger orders, they even send both sizing sets and physical samples to confirm color, size, and design accuracy before moving into full production. While modern performance fabrics can accommodate athletes who fall between sizes, keep in mind that finished garments might vary by up to +/-5% from the listed measurements.

"For bigger orders we follow a very strict cycle because we send out sizing sets AND custom samples to ensure the color, size, and design is 100% correct." – Wooter Apparel

When using sizing charts, measure a similar garment that fits well on a flat surface instead of directly measuring the player’s body. Also, decide whether your team prefers a looser, relaxed fit or a snug, compression-style look when selecting sizes.

Size Exchange Policies

Understanding exchange policies is just as important as getting the sizing right. Custom uniforms are non-returnable and non-exchangeable, so it’s crucial to communicate sizing policies clearly upfront. Uniforms also come with a manufacturing tolerance of +/-10%, and refunds or exchanges for sizing errors are not typically offered.

Wooter Apparel emphasizes this in their policy: "We can’t offer exchanges or returns for products made for your team so please ensure you select your sizing carefully."

However, designers should address manufacturing defects. Wooter Apparel, for instance, offers a 30-day warranty for manufacturing issues. If you report a problem within 7 days and provide visual proof, they’ll replace the defective item within roughly 15 business days.

To safeguard against sizing problems, always order sizing kits or physical samples before committing to a full team order. Skipping this step could leave you stuck with uniforms that don’t fit as expected, and designers typically won’t take responsibility for dissatisfaction related to fit or appearance.

7. What Materials and Sublimation Techniques Do You Use?

The materials and printing methods play a huge role in determining the performance and durability of uniforms. Knowing these technical aspects can help you make smarter choices about quality and how long your uniforms will last.

Performance Fabrics

When it comes to on-field performance, the quality of the material is everything. Most high-performance uniforms are made from 100% polyester with features like dry-fit, moisture-wicking, and breathable properties. This fabric is designed to pull sweat away from the body, keeping athletes dry and comfortable even during the most intense moments. Depending on the sport, fabric weights usually range from 140 to 280 GSM. Lighter fabrics work well for high-cardio activities, while heavier fabrics add durability for contact-heavy sports. Many uniforms also combine interlock mesh for strength with Lycra for flexibility, ensuring they meet the specific needs of different sports.

"Our material is a dry-fit, moisture-wicking, breathable 100% Polyester fabric. Generally, the body of the uniform is interlock mesh fabric for durability, and there is a Lycra fabric around the neck and shoulders for flexibility." – Wooter Apparel

But fabric is just one part of the equation. The printing method is just as important when it comes to quality.

Sublimation Quality and Durability

Sublimation printing is a game-changer. By heating ink to 380–420°F, this method bonds the design directly to the polyester fibers. Unlike screen printing or heat transfers, sublimation makes the design part of the fabric itself. The result? Vibrant colors that don’t crack, peel, or fade over time. Plus, the fabric stays soft and breathable, with no stiff or heavy texture. Many athletes even say sublimated uniforms feel lighter compared to traditionally printed ones.

Here’s a quick comparison of sublimation versus other printing methods:

| Feature | Sublimation Printing | Screen Printing / Heat Transfer |

|---|---|---|

| Fabric Feel | Soft, breathable; ink integrated into fabric | Heavier, with a plastic-like texture |

| Durability | Permanent; colors won’t crack, peel, or fade | Prone to cracking and peeling over time |

| Weight | Lightweight; no extra ink layers | Heavier due to added ink or film layers |

| Customization | Unlimited colors and all-over designs | Limited colors and specific print areas |

For the best results, ensure your uniforms are made from 100% polyester or blends with a high polyester content, as sublimation doesn’t work on cotton. Also, confirm that your designer uses the Pantone Matching System to get precise color accuracy. These details are key to creating professional, long-lasting uniforms.

8. What Is the Pricing Structure and Minimum Order?

When ordering custom apparel, it’s crucial to get a full breakdown of costs upfront. This includes everything from design and shipping to any potential add-on fees. Transparent pricing ensures smooth collaboration, and Wooter Apparel exemplifies this approach.

Detailed Pricing Breakdown

Once you’ve finalized your design and timeline, it’s time to clarify the costs to avoid surprises. At Wooter Apparel, the price of uniforms typically includes both design services and artwork, meaning you won’t be hit with unexpected charges for creating your custom look. Personalization, like player names and numbers, is also included. However, additional fees may apply for specific needs. For example, if you need your order faster than the standard 3–4 week production time, there’s a 25% rush fee to deliver in as little as 10 business days.

Shipping costs depend on weight and delivery method. Plan to spend about $2–$3 per jersey or $4–$5 per set, with heavier items incurring higher fees. To avoid extra graphic fees, submit your logos in vector format. Always ask about any additional charges beyond the base price to ensure you’re fully informed.

"We have price discounts on higher quantities because production costs go down. We are very upfront with our pricing." – Wooter Apparel

Minimum Order Requirements

Understanding order minimums is just as important as knowing the pricing details. Wooter Apparel offers bulk pricing starting at 10–25 units, with even greater discounts for larger orders. For individual purchases, their Apparel Platform has no minimum order requirement.

To save more, consider bundling items. Packages like the All-Star or MVP options combine home and away uniforms with extras like backpacks and warmup gear, offering better value than buying each item separately. For smaller teams or one-off purchases, the "Name Your Own Price" feature allows you to submit your budget or a competing quote. The designer may work with you to match or beat it.

9. How Do You Handle Revisions and Design Changes?

Creating a uniform design is rarely a one-and-done process – it’s all about refining the details through feedback. Knowing how revisions are handled can help you manage your timeline and communicate your ideas more effectively.

Number of Allowed Revisions

At Wooter Apparel, you’re allowed three revisions on your initial concepts and three additional revisions after selecting your favorite design. The team typically responds to feedback within 1–3 business days.

When providing feedback, clarity is key. Instead of vague comments like "fix the fit", aim for specifics such as, "lengthen the sleeve by 2 inches." Including updated measurements or annotated photos can make a big difference in how well the design team addresses your concerns.

"Communicating your designs isn’t a one-shot thing, it’s an iterative process. There will be multiple rounds of revision." – Sewport Support Team

Wooter Apparel simplifies the revision process by using tools that make collaboration easy and efficient.

Design Collaboration Tools

Smooth communication is essential for effective revisions, and Wooter Apparel’s platform is built with this in mind. Their online apparel builder allows you to customize colors, add logos, and personalize player names and numbers using a simple drag-and-drop interface. Thanks to 3D visualization, you can preview lifelike mockups before production even starts. Plus, their 24/7 live chat and email support ensure you’re always connected to the in-house graphics team.

10. What Support Do You Offer After the Design Is Complete?

Once your design is finalized and delivered, the journey doesn’t end there. Long-term support is essential to meet your team’s evolving needs. Whether it’s adding new players mid-season, replacing worn-out gear, or managing unexpected issues, Wooter Apparel ensures you’re covered.

Reordering and Repair Options

Wooter Apparel keeps your designs on file, making it simple to reorder matching uniforms whenever needed. Whether you’re replacing a damaged jersey or outfitting a new team member, there’s no need to start the design process all over again.

They also offer a 30-day warranty for rips or defects. If you encounter an issue, just provide photo documentation within 7 days to qualify for a free replacement.

"Wooter Apparel has a guaranteed warranty of 30 days for all custom uniforms and apparel upon delivery. This means if your item rips or has defects, we can replace it free of charge if proper documentation including photos is sent to us." – Wooter Apparel

Once verified, replacement items typically arrive within 15 business days. For reorders, most items require a minimum of 5 pieces, but some self-serve platform options allow for smaller quantities with no minimums.

Supporting Team Growth

As your team expands, Wooter makes it easy to add new uniforms without disrupting consistency. Small add-on orders are available, though they come with a surcharge: 25% for initial orders of 10+ pieces and 40% for orders under 10. These additional items are delivered within the standard 3–4 week timeframe.

Thanks to Wooter’s sublimation printing, your uniforms maintain consistent colors and designs over time. This process ensures the colors are embedded into the fabric, preventing peeling, cracking, or fading – even after years of use. To keep everything uniform, it’s important to document your original specifications, including measurements, font sizes, and exact Pantone color codes. This attention to detail ensures that uniforms ordered in future seasons will match seamlessly with the originals.

Conclusion

Starting with the right questions can make the entire design process much smoother. By tackling key topics like sport-specific requirements, branding, customization, timelines, sizing, materials, pricing, revisions, and support early on, you ensure that everyone is on the same page. This proactive approach helps avoid costly mistakes and delays, keeping your project on track.

Wooter Apparel’s reputation speaks volumes, with a 4.9-star rating from 1,239 reviews and uniforms delivered to teams in 25 countries. Their expertise in full sublimation printing means your designs won’t fade or peel, and their free professional design services take the hassle out of creating your ideal look. Operating out of their New York City headquarters, their team of over 40 professionals handles everything from tech to design and customer support. This means you’re not just getting uniforms – you’re getting a dedicated partner invested in your team’s success. Plus, with a standard turnaround time of 16 business days (or as quick as 10 days for rush orders), you can count on having your gear ready when you need it.

FAQs

How can I make sure the colors and logos on my uniforms look perfect and stay consistent?

To guarantee your uniforms feature precise and consistent colors and logos, make sure to provide your designer with vector files such as .ai or .pdf for your logos. Additionally, share your brand guidelines, including any specific Pantone color codes, to ensure everything stays uniform. Before production begins, ask for mockups or physical samples to verify that the colors, logo placement, and scaling align with your vision. These steps will ensure your team looks polished and professional, both on and off the field.

How can I ensure custom uniforms fit my team perfectly?

When it comes to getting the right fit for custom uniforms, start by measuring each player carefully with a flexible measuring tape. Use the manufacturer’s size chart as your guide, and double-check every measurement to ensure accuracy. Don’t forget to factor in personal fit preferences – some players might prefer a snug fit, while others might like a bit more room. Also, keep in mind how the fabric may stretch or move during play. These steps will help ensure the uniforms are both comfortable and confidence-boosting for everyone.

What makes sublimation printing a great choice for sports uniforms?

Sublimation printing stands out as a fantastic choice for sports uniforms because it delivers bold, full-color designs that become a permanent part of the fabric. This means no peeling, cracking, or fading – even after countless washes.

Beyond durability, the process ensures the fabric remains soft and breathable, which is essential for keeping athletes comfortable and performing at their best. Plus, sublimation opens the door to fully customizable, all-over designs, helping teams achieve a distinctive and polished appearance on the field or court.