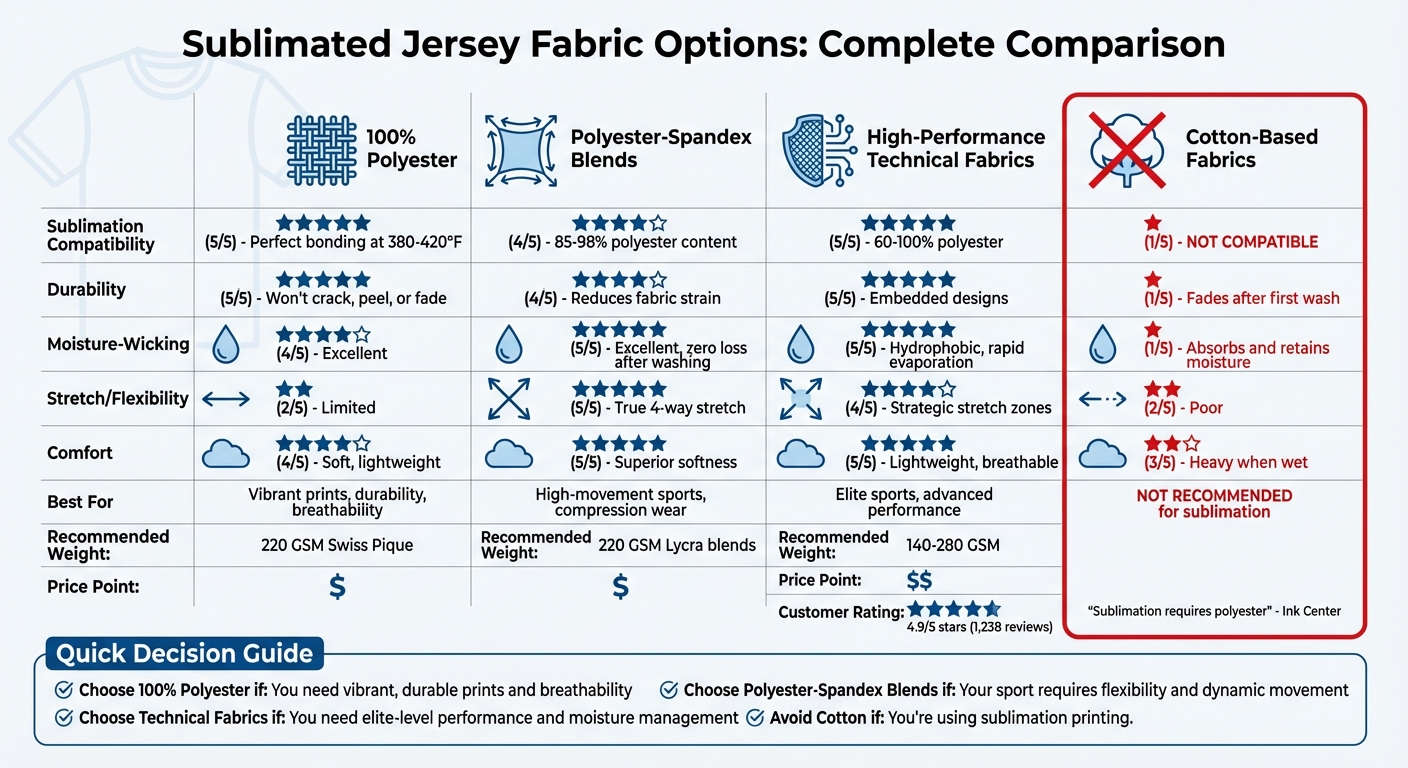

Sublimated jerseys are a game-changer for sportswear, offering vibrant, long-lasting designs that become part of the fabric itself. The process works best with polyester-based materials, as they bond effectively with sublimation dyes. Here’s a quick breakdown of fabric options:

- 100% Polyester: Ideal for sharp, durable prints. Lightweight, moisture-wicking, and soft, but with limited stretch.

- Polyester-Spandex Blends: Adds stretch and flexibility for high-movement sports. Slightly less vibrant prints but great for comfort and performance.

- High-Performance Technical Fabrics: Designed for elite sports, these fabrics balance durability, moisture-wicking, and breathability.

- Cotton-Based Fabrics: Not suitable for sublimation. Prints fade quickly, and the material lacks moisture management.

Choose based on your team’s needs – polyester for durability, blends for flexibility, or technical fabrics for advanced performance.

Sublimated Jersey Fabric Comparison: Polyester vs Blends vs Technical Fabrics

Best & Worst Shirts for Sublimation | Comparison & Washing Tests!

1. Polyester

When it comes to sublimated jerseys, 100% polyester is the go-to material. Why? Because polyester reacts perfectly to the sublimation process. When heated to temperatures between 380–420°F, the fabric’s pores open up, allowing gaseous dye to seep in and permanently settle as the material cools down.

Sublimation Compatibility

Polyester is a must for sublimation printing. As Ink Center puts it:

Sublimation requires polyester.

Natural fibers like cotton, wool, or silk simply don’t work for sublimation because they can’t bond with sublimation ink. For the best results, stick to white or light-colored polyester. Since sublimation dyes are transparent, they won’t show up well on darker fabrics. Also, smooth-face polyester gives the sharpest print quality, while textured or brushed fabrics might blur the design. These unique bonding traits also make polyester a durable choice for long-lasting performance.

Durability

Sublimated designs on polyester are built to last. Because the dye embeds directly into the fibers, the designs won’t crack, peel, or fade – not even after countless washes or extended exposure to sunlight. Polyester’s natural strength and flexibility also help it resist sagging or losing shape, unlike natural fibers. For sports like baseball and softball, 220 GSM Swiss Pique polyester strikes the perfect balance of weight and durability, while Polyester Doubleknit (PDK) offers the toughness needed for pants. Beyond its toughness, polyester is also excellent at managing moisture.

Moisture-Wicking Capability

Unlike cotton, polyester doesn’t hold onto sweat. Instead, it pulls moisture away from the skin and moves it to the fabric’s surface, where it evaporates quickly. And because sublimation embeds the dye directly into the fibers – without adding extra layers – the fabric’s natural moisture-wicking ability stays intact. This means jerseys remain lightweight and breathable, even during intense games.

Comfort and Flexibility

One of the best things about the sublimation process is how it leaves polyester jerseys feeling soft and smooth. There’s no heavy ink or plastic layer sitting on the surface. This keeps the fabric breathable and comfortable to wear. Plus, the lightweight feel doesn’t restrict movement – critical for high-energy sports like baseball and softball. While 100% polyester offers some natural stretch, blending it with materials like spandex can add extra flexibility for even more dynamic play.

At Wooter Apparel, these qualities make polyester the material of choice for sublimated jerseys. The result? Vibrant designs, unbeatable durability, and top-notch comfort that players can count on game after game.

2. Polyester Blends with Spandex and Lycra

When it comes to active sports, polyester blends with spandex or Lycra bring a level of stretch that pure polyester simply can’t offer. These blends marry polyester’s sublimation-friendly nature with the flexibility athletes need for intense movements like sliding, diving, or stretching.

Sublimation Compatibility

One of the standout features of these blends is their compatibility with sublimation printing. With a polyester content ranging from 85% to 98%, the fabric retains its ability to bond effectively with sublimation dyes during the heat process. The addition of spandex or Lycra doesn’t interfere with this process but instead enhances the fabric’s versatility.

"These fabrics are a combination of polyester with Spandex or Elastane woven into the fabric to provide superior stretch and elasticity."

Because the dye is infused directly into the fibers, designs like team logos and numbers stay sharp and intact, even when the fabric is stretched. This allows for high-resolution prints and intricate graphics while maintaining durability under intense use.

Durability

These blends are built to handle the demands of dynamic movement. While 100% polyester can sometimes feel rigid under stress, polyester-spandex blends provide a level of flexibility that reduces fabric strain. This stretchability helps absorb the impact of sudden or repetitive movements, lowering the risk of tears or seam failures. Fabrics like Suplex and Neoprene (98% polyester, 2% elastane/spandex) are excellent examples, offering lasting color vibrancy and resistance to pilling.

Moisture-Wicking Capability

Another major advantage of these blends is their ability to manage moisture effectively. They wick sweat away from the skin, moving it to the fabric’s outer surface where it evaporates quickly. This keeps jerseys lightweight and comfortable, even during the most intense moments of a game.

"The technology is in the material itself, not a coating applied later. Washing these fabrics creates zero loss in moisture management performance."

Comfort and Flexibility

The stretch provided by these blends makes them a top choice for sports that demand dynamic movement. Strategic use of Lycra and interlock mesh construction enhances flexibility, making these fabrics ideal for form-fitting gear like compression wear, wrestling singlets (often around 220 GSM Lycra blends), or cycling jerseys. These blends offer true 4-way stretch, allowing unrestricted movement in all directions. Plus, since sublimation printing doesn’t add any weight or texture, the fabric retains its natural softness.

At Wooter Apparel, polyester-spandex blends are a favorite for teams looking for jerseys that bring together flexibility, comfort, and vibrant, long-lasting designs. These fabrics are paving the way for the next generation of high-performance sportswear.

3. High-Performance Technical Fabrics

High-performance technical fabrics are at the forefront of sublimated jersey technology. These materials take things a step further than standard polyester by incorporating features tailored to meet the challenges of elite-level sports. Typically weighing between 140 and 280 GSM, these fabrics strike a balance between durability and performance, catering to the specific needs of various sports.

Sublimation Compatibility

These fabrics are specifically designed for sublimation printing, requiring at least 60% polyester content, though 100% polyester remains the gold standard for achieving the best results. This compatibility ensures that the sublimation process works seamlessly while delivering exceptional visual quality.

Durability

One standout feature of these fabrics is how the sublimation process embeds designs directly into the material. This ensures that logos, numbers, and graphics won’t crack, peel, or fade, no matter how hard the jersey is pushed during its lifespan. They’re also ideal for handling intricate, multi-color designs without sacrificing durability. For instance, in 2019, the Tampa Bay Lightning of the NHL used technical fabrics to create jerseys with detailed, long-lasting designs.

Moisture-Wicking Capability

Beyond their durability, these fabrics excel at moisture management. Engineered to be hydrophobic, technical polyester fabrics don’t absorb sweat like cotton does. Instead, they actively wick moisture away from the skin to the fabric’s outer surface, where it evaporates quickly. This keeps the jerseys lightweight and ensures athletes stay dry and comfortable, even during intense play.

Comfort and Flexibility

Another advantage of these fabrics is that they don’t add any extra weight or bulk to the garment. Jerseys maintain their soft, lightweight, and breathable qualities, providing athletes with comfort throughout their performance.

"The nature of sublimation means that the prints are never heavy or thick. The garment is unchanged by the process, save for the addition of your art." – Wooter Apparel

For added flexibility, technical fabrics like interlock mesh offer a sturdy base, while materials such as Lycra or spandex are incorporated into high-movement areas like the neck and shoulders. This enhances mobility without compromising the integrity of the sublimated design. Wooter Apparel’s high-performance fabrics have earned a stellar 4.9/5 star rating from 1,238 reviews, with customers frequently highlighting the vibrant colors, soft texture, and the lightweight feel of the jerseys as game-changers for performance.

sbb-itb-4d95ad3

4. Cotton-Based Sublimation Fabrics

Cotton fabrics simply don’t work for sublimated jerseys. Sublimation ink bonds chemically with polyester, which means cotton can’t hold the ink effectively.

Sublimation Compatibility

Here’s the science: sublimation works because polyester fibers open up under heat, allowing the ink – turned into gas – to seep in and bond. Cotton, on the other hand, doesn’t have this ability. On 100% cotton, designs might look fine initially but will fade after the first wash.

"You cannot do sublimation on 100% cotton. Sublimation must be done on 100% polyester for the best results. You can print on cotton shirts but it is not the same process as sublimation." – Wooter Apparel

Even polycotton blends fall short. While they might hold some ink, the prints often appear dull and faded compared to the vibrant results you get with 100% polyester. For those looking for a softer, more natural feel without compromising print quality, fabrics like Suplex (85% polyester/15% spandex) are a solid option. Suplex offers a cotton-like texture with 4-way stretch and remains fully compatible with sublimation. Choosing cotton or blends not only affects print quality but also reduces the fabric’s durability.

Durability

Durability is another issue with cotton-based fabrics. Since sublimation ink doesn’t bond well to cotton, designs won’t last long. Even in polycotton blends, the ink adheres only to the polyester fibers, leaving the cotton strands untouched. Over time, this results in a faded, vintage look that worsens with repeated washes.

Moisture-Wicking Capability

Cotton also struggles with moisture management. It absorbs and retains moisture, making jerseys feel heavy and clingy during intense activity. This lack of breathability can hinder performance, especially in sports. Polycotton blends offer slight improvements, but they still don’t match the moisture-wicking efficiency of 100% polyester fabrics. For athletes who need lightweight, durable jerseys that can handle frequent washing, polyester remains the go-to choice. Cotton-based fabrics simply can’t compete when it comes to performance and longevity.

Pros and Cons

Here’s a quick rundown of the strengths and weaknesses of various fabric types to help with your selection process.

100% Polyester

This fabric delivers bold, long-lasting prints and offers excellent breathability. However, it has limited stretch, and snags can expose the fibers underneath .

Polyester-Spandex Blends

Known for their superior stretch and snug fit, these blends are ideal for sports involving high levels of movement. They’re softer and more comfortable than pure polyester, especially when the polyester content is above 80% . The downsides? Slightly less vibrant colors and a higher price point . Still, they strike a great balance between flexibility and print quality, making them a solid choice for teams needing both performance and style.

High-Performance Technical Fabrics

Fabrics like stretch mesh or aerofiber excel in moisture-wicking and ventilation, keeping athletes dry and comfortable . On the flip side, technical meshes with visible holes can be less resistant to snags compared to interlock weaves. These advanced materials cater to the rigorous demands of elite-level sports.

Cotton-Based Fabrics

Cotton doesn’t work with sublimation printing since the ink doesn’t bond well with its fibers, leading to designs that fade or wash out quickly . Additionally, cotton absorbs moisture rather than wicking it away, which can make jerseys feel heavy and clingy during games.

Each fabric type comes with its own trade-offs, allowing teams to select materials that align with their specific performance and design needs.

Conclusion

The fabric you choose plays a critical role in both the quality of your design and the performance of your team. The right material depends entirely on your team’s specific demands and priorities.

For sublimation, 100% polyester stands out as the top choice. Its molecular structure ensures designs stay intact – no cracking, peeling, or fading over time. If your team values vibrant colors and long-lasting durability, pure polyester is a reliable option.

When flexibility is key – such as for sports like basketball or soccer – polyester blends with spandex or lycra are ideal. These materials provide the stretch and snug fit necessary for explosive movements. While they may cost a bit more, the added comfort and improved range of motion make them a worthwhile investment. On top of that, technical fabrics with advanced moisture-wicking abilities excel at keeping athletes dry and comfortable, even during the most intense games, thanks to their breathability and temperature control.

A great example of this approach is Wooter Apparel, which uses 220gsm Swiss Pique interlock mesh polyester for the main body of jerseys, paired with polyester-lycra blends in high-movement areas like the neck and shoulders. This thoughtful combination ensures durability where it’s needed while providing flexibility in key zones, delivering a professional-grade uniform that meets the demands of competitive sports.

FAQs

Why is polyester the best fabric for sublimated jerseys?

Polyester stands out as the go-to material for sublimated jerseys thanks to its ability to bond chemically with sublimation ink. This results in bright, durable designs that hold up against fading, even after countless washes and wears.

Beyond its visual advantages, polyester offers practical benefits. It’s lightweight, tough, and moisture-wicking, making it ideal for athletes. By keeping players cool and comfortable, it allows them to stay focused on their performance without any distractions.

What makes polyester-spandex blends a great choice for sportswear?

Polyester-spandex blends bring together the toughness and moisture-wicking properties of polyester with the flexibility and stretchiness of spandex. This combination results in a fabric that’s breathable, dries quickly, and moves effortlessly with the wearer – making it a top choice for high-performance sportswear.

The stretch in this blend ensures a snug yet comfortable fit, boosting mobility and reducing muscle fatigue while holding its shape through repeated wear. These features make it an excellent option for sublimated jerseys and other activewear, offering both comfort and vibrant, long-lasting designs. Wooter Apparel incorporates this blend into their custom team uniforms, delivering performance and style in every piece.

Why isn’t cotton a good choice for sublimation printing?

Cotton fabrics fall short when it comes to sublimation printing. The reason? Their natural fibers lack the polymer structure necessary for the sublimation dye to bond effectively. Without this connection, the ink merely rests on the fabric’s surface, leading to designs that fade quickly or disappear entirely after washing.

For bold, durable designs that truly last, polyester-based fabrics are the go-to choice. The dye forms a chemical bond with the polyester, resulting in a finish that’s both long-lasting and visually striking.