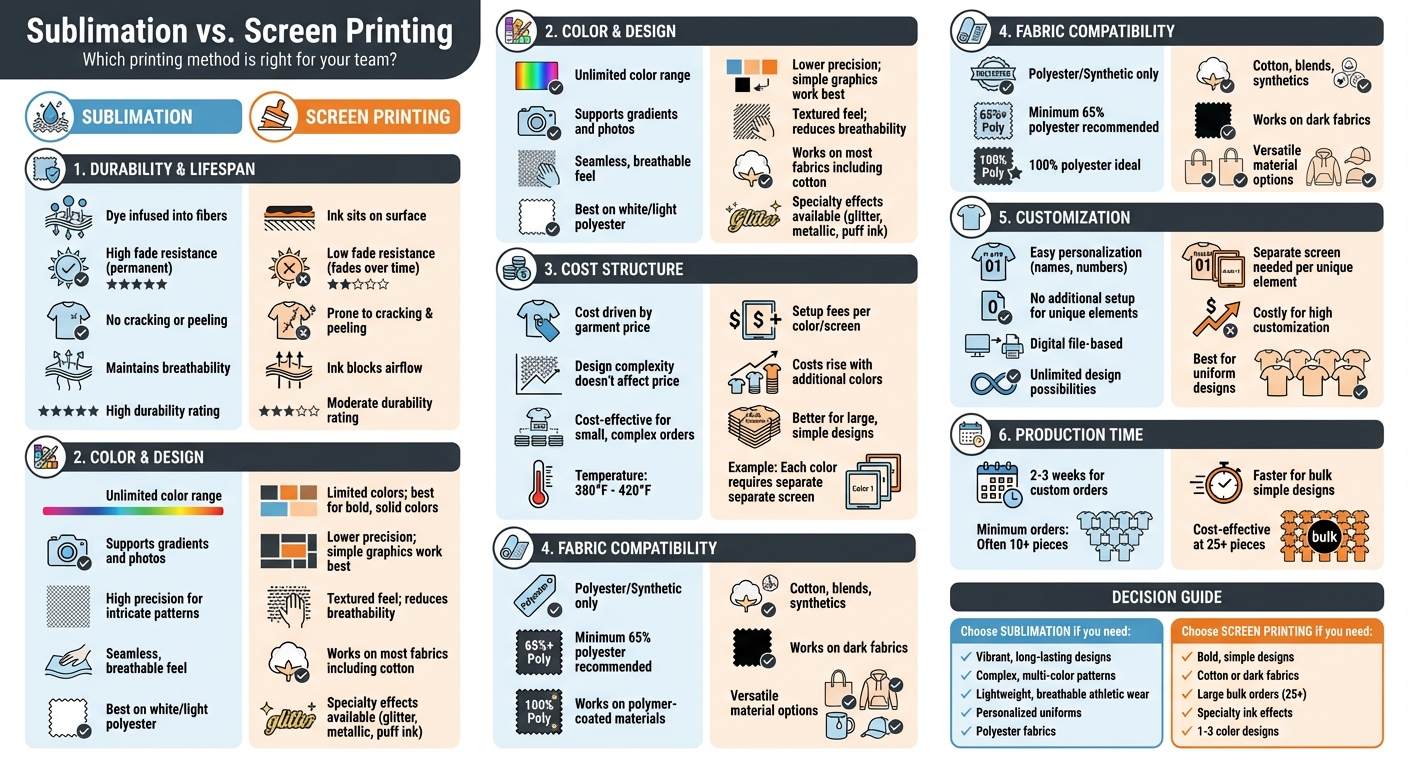

Sublimation and screen printing are two popular methods for applying designs to apparel, each with distinct strengths and limitations. Here’s a quick breakdown:

- Sublimation: Bonds dye directly into polyester fabric fibers, ensuring long-lasting, fade-resistant designs. Best for detailed, multi-color designs. Works only on polyester or light-colored synthetic fabrics.

- Screen Printing: Applies ink on fabric surfaces, ideal for bold, simple designs on various materials like cotton. Costs rise with additional colors or details.

Quick Overview:

- Durability: Sublimation designs last longer without cracking or peeling. Screen printing may wear over time.

- Fabric Compatibility: Sublimation works only on polyester; screen printing is versatile across fabrics.

- Cost: Sublimation is cost-effective for small, complex orders. Screen printing is better for large, simple designs.

- Customization: Sublimation easily handles intricate, personalized designs. Screen printing is less efficient for customization.

Which to Choose? For vibrant, lightweight, and long-lasting designs on polyester, go with sublimation. For simpler, bold designs on cotton or darker fabrics, screen printing is a solid choice.

Sublimation vs Screen Printing: Complete Comparison Guide

Sublimation Printing vs Screen Printing: Discover with Colour Vistas

What Is Sublimation?

Sublimation is a process that transforms solid ink into gas under heat and pressure, bonding dye permanently to polyester fibers through a specialized transfer method. This technique embeds the design directly into the fabric, creating a smooth, integrated finish rather than a surface-level print.

The process only works on polyester or polymer-coated materials, as the dye chemically bonds with synthetic fibers. As CustomJersey.com explains:

The dye particles are designed to bond with polyester, and ignore everything else.

While sublimation is incompatible with 100% cotton fabrics, it produces outstanding results on polyester-based materials, making it a go-to choice for athletic wear.

The finished garment feels smooth and untextured because the dye becomes part of the fabric itself. This lightweight, breathable quality is critical for performance apparel, ensuring athletes stay comfortable during intense activities.

How the Sublimation Process Works

The process starts with a digital design printed onto special transfer paper using sublimation dyes. This paper is then placed on white or light-colored polyester fabric and exposed to high temperatures – ranging between 380°F and 420°F – under significant pressure.

At these temperatures, the polyester fibers’ pores open, and the solid ink transitions into a gas. The gaseous dye penetrates the open fibers, and as the material cools, the pores close, permanently locking the dye into the fabric’s molecular structure. This creates a design that becomes inseparable from the material.

For optimal results, the fabric should contain at least 65% polyester. Higher polyester content enhances the quality, which is why 100% polyester is often used for athletic uniforms. Additionally, sublimation works best on white or very light-colored materials since the transparent dyes cannot produce white ink.

Benefits of Sublimation

Sublimation offers exceptional durability because the dye bonds directly with the fabric. Designs resist fading, cracking, and peeling, maintaining their appearance even after repeated washing or prolonged exposure to sunlight. Unlike traditional printing methods that layer ink on the fabric, sublimated patterns stay vibrant throughout the garment’s life.

Another advantage is the broad range of color possibilities. The digital printing process (CMYK) enables detailed photographic images, complex gradients, and intricate patterns – all at a flat cost. Unlike screen printing, which charges more for additional colors, sublimation handles full-color designs without extra fees.

The absence of a thick ink layer preserves the fabric’s natural breathability and moisture-wicking properties. This makes sublimation particularly well-suited for athletic uniforms where performance and comfort are priorities. Additionally, the process is eco-friendlier, producing no wastewater and utilizing water-based inks.

Drawbacks of Sublimation

One limitation of sublimation is its reliance on polyester materials. Natural fibers like cotton lack the pore structure required for the dye to bond effectively, limiting fabric choices for those who prefer cotton-based clothing.

Cost can also be a factor, especially for smaller orders. While some providers accommodate single-unit requests, many require minimum orders of 10 or more for custom team apparel. For instance, custom cycling jerseys might cost around $23.77 per unit for orders of 5 but drop to approximately $15.68 per unit for orders of 500. Additionally, some manufacturers charge a one-time setup fee of about $47.50.

Lastly, sublimation can involve longer production times. Custom orders typically take 2 to 3 weeks to complete, which may pose challenges for teams needing quick turnarounds.

What Is Screen Printing?

Screen printing, often called silk screening, is a hands-on stencil technique where ink is pressed through a mesh screen onto a fabric surface. This method has been a staple for creating custom apparel, particularly on cotton garments, due to its effectiveness and reliability.

What makes screen printing stand out is its flexibility. While it’s commonly used on fabric, it can also be applied to materials like wood, metal, plastic, glass, and paper when paired with specialty inks. This adaptability has cemented its role as a popular choice for custom team apparel.

Screen printing shines when it comes to bold, simple designs with a limited color range. It’s ideal for team logos, graphic T-shirts, and text-based designs that need vibrant and clear results.

How the Screen Printing Process Works

The screen printing process involves several distinct steps. First, a separate stencil screen is created for each color in the design. The design is then transferred onto a mesh screen. Using a squeegee, ink is pushed through the mesh, applying each color one layer at a time. Once all the colors are added, the garment is heated to cure the ink and ensure durability.

However, the process becomes increasingly complex as the number of colors in a design grows. Since each color requires its own screen, setup can be time-consuming and costly, making this technique most practical for designs with one to three colors.

Benefits of Screen Printing

Screen printing offers a clear advantage when it comes to bulk orders. While the initial setup requires creating individual screens for each color, the cost per unit drops significantly as the order size increases. This makes it a cost-effective option for orders of 25 pieces or more.

Durability is another strong point, especially when plastisol inks are used. These inks produce vibrant, opaque colors that stand out even on dark fabrics – something sublimation printing often struggles to achieve. Screen printing has been a trusted method for custom apparel for decades, thanks to its ability to deliver bold and long-lasting designs.

What sets screen printing apart is the option to use specialty inks. These allow for effects that digital methods can’t replicate, such as puff ink for raised textures, metallic finishes, glitter, and glow-in-the-dark elements. This creative flexibility provides designers with tools to make their work stand out.

Drawbacks of Screen Printing

Despite its advantages, screen printing has its limitations. One common issue is durability. Since the ink sits on the surface of the fabric rather than bonding with the fibers, it’s more prone to cracking, peeling, and fading over time. This is particularly problematic for athletic uniforms that see heavy use.

Jana Magonova, Senior Content Writer at Printful, explains:

"The more colors you print on the garment, the thicker the print will be. Since the ink sits on top of the garment, screen printing can be less durable over time than sublimation printing."

Another challenge is reproducing complex designs. Photorealistic images, intricate details, and smooth gradients are difficult – and expensive – to achieve with stencils. Each additional color increases setup time and costs, making this method less suitable for highly detailed artwork.

Environmental concerns also come into play. Screen printing often relies on plastisol inks, which are non-biodegradable and can be toxic. The process also uses large amounts of water and harsh chemicals to clean the screens, raising sustainability questions.

sbb-itb-4d95ad3

Sublimation vs. Screen Printing: Direct Comparison

Now that we’ve broken down each printing method, let’s directly compare their key traits, especially when it comes to team uniforms.

Durability and Lifespan

The way ink interacts with fabric is a game-changer for durability. Sublimation works by embedding dye directly into the fabric fibers at high temperatures (between 380°F and 420°F), essentially making the ink part of the material. On the other hand, screen printing applies plastisol ink to the surface of the fabric, creating a layer that sits on top instead of bonding with the fibers.

This difference becomes obvious over time. Sublimation ensures the design won’t chip, peel, or crack – even after countless washes – because the dye is locked into the fabric. In contrast, screen printing is more prone to wear and tear, with surface ink that can deteriorate over time.

| Feature | Sublimation | Screen Printing |

|---|---|---|

| Application | Infused into fibers | Sits on surface |

| Fade Resistance | High (Permanent) | Low (Fades over time) |

| Cracking & Peeling | No | Yes |

| Breathability | Maintains fabric pores | Ink blocks airflow |

| Durability | High | Moderate |

Another aspect to consider is the fabric’s breathability. Sublimation preserves the material’s natural airflow and moisture-wicking qualities, making it ideal for sportswear. In contrast, screen printing adds weight and can restrict airflow, which may not be ideal for high-performance activities like soccer or baseball.

These durability factors naturally lead us to consider how each method performs in terms of color and design.

Color Quality and Design Options

Sublimation offers endless color possibilities, excelling with gradients, photographic images, and intricate designs. The digital process allows for seamless, edge-to-edge patterns that can cover every inch of a garment – even across seams, sleeves, and collars.

Screen printing, however, shines with bold, vibrant colors, especially on darker fabrics – something sublimation struggles to achieve effectively. That said, screen printing is better suited for simpler designs because each color requires a separate screen, making it less practical for detailed or gradient-heavy graphics.

| Feature | Sublimation | Screen Printing |

|---|---|---|

| Color Range | Unlimited; supports gradients and photos | Limited; best for solid, bold colors |

| Design Detail | High precision; intricate patterns | Lower precision; best for simple graphics |

| Feel (Hand) | Seamless and breathable | Textured; can reduce breathability |

| Fabric Compatibility | Best on white/light 100% polyester | Works on most fabrics, including cotton |

Screen printing also has unique capabilities for adding special effects like glitter, metallic finishes, puff ink, and glow-in-the-dark elements – features that sublimation cannot replicate.

Customization Capabilities

When it comes to team uniforms, customization is a big deal. Sublimation is a standout here, as it directly uses digital files, making it easy and cost-effective to personalize each piece. Adding player names, numbers, or unique graphics doesn’t require additional setup, keeping costs consistent.

Screen printing, by contrast, requires a separate screen for each unique element, which can make customization costly and time-consuming. While secondary methods like heat-press vinyl can help, they add another layer of complexity.

Daniel Shultz, General Manager at Sphere Sport, sums it up well:

Sublimation printing allows for unlimited design possibilities. You can create full-color, photorealistic prints with intricate details. There are no limits to the colors, patterns, or images that you can use.

For teams looking for fully personalized uniforms, sublimation is the go-to choice. However, for straightforward, bold logos on bulk orders, screen printing remains a budget-friendly option.

At Wooter Apparel, we use sublimation to deliver vibrant, long-lasting designs with unparalleled customization options.

Cost and Fabric Requirements

After evaluating design performance, the next step is to consider cost and fabric compatibility, which play a key role in selecting the right printing method.

Cost Breakdown by Order Size

Sublimation and screen printing differ quite a bit when it comes to pricing. Sublimation has no setup fees, no matter how complex the design or how many colors are involved. On the other hand, screen printing requires a separate screen for each color, which can drive up initial costs significantly. As Travis Woodham from 323 Sports puts it:

"If you’re wanting a fancy uniform full of intricate designs and fine details, you will pay a fortune in fees for screen printing. With sublimation, there are no screen fees regardless of the design!"

For smaller orders, sublimation tends to be more budget-friendly because it avoids setup fees entirely. However, for larger orders with simple designs – think bold graphics with only one or two colors – screen printing can be a cost-effective choice. That said, screen printing costs rise quickly with each additional color or print location. Sublimation, by contrast, keeps pricing steady, regardless of how intricate or colorful the design is.

These cost considerations tie directly into fabric compatibility, as outlined below.

Compatible Fabric Types

Fabric choice is another area where these two methods differ significantly. Sublimation works exclusively with polyester-based or polymer-coated fabrics, as these materials allow the ink to bond effectively. Screen printing, however, is more versatile and can be applied to cotton, blends, and synthetics. But remember, each added color increases the cost of screen printing.

| Method | Compatible Fabrics | Cost Driver |

|---|---|---|

| Sublimation | Polyester / Synthetic | Driven by garment cost; design complexity doesn’t affect price |

| Screen Printing | Cotton, Blends, Synthetics | Costs rise with additional colors and print locations |

Sublimation’s fabric limitations make it an ideal option for performance sportswear, where polyester’s moisture-wicking and breathability are key. While screen printing offers more flexibility in fabric choices, it may not deliver the same durability or airflow benefits as sublimation.

For teams looking for affordable, high-performance uniforms, fully sublimated designs – like those provided by Wooter Apparel – offer a smart and practical solution, combining cost efficiency with premium functionality.

Conclusion: Choosing the Right Method for Your Team

When it comes to selecting the best printing method for your team, factors like fabric type, design intricacy, and budget play a crucial role. If your team opts for polyester uniforms and requires bold, multi-color designs with personalized names and numbers, sublimation is the go-to option. This method embeds dye directly into the fabric, ensuring designs won’t crack, peel, or incur hefty setup fees. On the other hand, for those who prefer 100% cotton or need simpler, one-color designs, screen printing remains a practical and effective choice since the ink sits on the fabric’s surface.

Sublimation stands out for its durability, lightweight feel, and ability to handle complex designs. As Wooter Apparel puts it:

The prints are never heavy or thick… sublimated uniforms are much lighter to play in.

With a 4.9/5-star rating from 1,239 reviews, Wooter Apparel’s sublimated uniforms are praised for vibrant colors and high-quality materials.

For orders of 10 or more pieces, sublimation offers unlimited color options without additional fees, making it a cost-effective choice for teams seeking fully customized, professional-grade uniforms. In the end, your decision boils down to the fabric type, design needs, and order size that best align with your team’s goals for performance and style.

FAQs

What is the difference between sublimation and screen printing?

When it comes to durability, color vibrancy, and design flexibility, sublimation and screen printing take different approaches. Sublimation embeds dye directly into polyester fabric, resulting in vibrant, long-lasting designs that resist cracking, peeling, or fading. This method is ideal for intricate, multi-colored, or all-over designs, making it a popular choice for team uniforms.

On the flip side, screen printing involves applying ink onto the surface of the fabric. It’s great for bold, simple designs but tends to wear down more quickly, especially on stretchy materials.

Cost is another factor to consider. Screen printing is often the more affordable option for large orders with basic designs. However, sublimation excels when you need detailed, high-quality artwork that can withstand heavy use. For teams wanting uniforms that truly stand out and last, sublimation is hard to beat.

Can sublimation printing be done on cotton fabrics?

Sublimation printing doesn’t work well on cotton fabrics because it relies on bonding dye to synthetic fibers like polyester. Cotton lacks the molecular structure needed for this bonding process, making it incompatible with sublimation.

For bold, long-lasting designs, fabrics with a high polyester content are the way to go. If you’re thinking about creating custom team uniforms or apparel, fully sublimated designs deliver exceptional color brilliance and durability when applied to suitable materials.

What makes sublimation ideal for athletic uniforms?

Sublimation is a fantastic choice for athletic uniforms because it produces bright, durable designs that stay intact even after countless washes. Unlike older printing methods, sublimation embeds the design directly into the fabric, making it resistant to fading, cracking, or peeling while keeping the surface smooth.

This technique pairs perfectly with polyester fabrics, known for being lightweight and breathable – ideal for activewear. With sublimated uniforms, athletes get the best of both worlds: standout designs and the comfort needed to perform their best, whether on the field or off.