Sublimation printing has transformed college basketball uniforms by replacing older methods like screen printing and tackle twill. This process uses high heat to bond dye directly into polyester fabric, making designs lighter, more durable, and resistant to cracking or peeling. Sublimated uniforms weigh about 11.4 ounces compared to 26.8 ounces in the 1990s, reducing player fatigue over a season. They also allow for unlimited design options, including all-over prints and multi-color patterns, without extra costs. Additionally, sublimation enhances ventilation and moisture-wicking, improving player comfort during games. While it offers lasting quality and design flexibility, minor drawbacks like fabric snags revealing white underlayers exist. However, for teams prioritizing performance and style, sublimation is a standout choice.

How College Basketball Uniforms Changed Over Time

In the early days of college basketball, uniforms were made from wool and cotton – materials that were far from ideal for athletic performance. Wool, in particular, was a major issue. It was heavy, trapped heat, and soaked up sweat, making jerseys heavier and more uncomfortable as games went on. Eventually, synthetic fabrics like polyester, nylon, and dazzle (a shiny material often used for shorts) replaced these natural fibers, leading to lighter uniforms. However, these advancements didn’t solve everything, as decoration techniques remained outdated.

Team logos and player numbers were applied using methods like screen printing, heat transfer, embroidery, and tackle twill. Instead of being part of the fabric, these designs were layered on top, making them vulnerable to wear and tear. Over time, repeated washing caused graphics to crack, chip, or peel.

This ongoing issue led to calls for innovation within the industry. Wooter Apparel captured the sentiment perfectly:

"Yet when logos and emblems faded and jersey numbers began to crack over time, something had to give."

The turning point came when necessity drove innovation. In 1957, Samuel Simon invented sublimation printing in Manchester, England. While digital textile printing made strides from the 1970s to the 1990s, sublimation became the go-to method in the 2000s for creating integrated designs. Unlike older techniques, sublimation fused designs directly into the fabric, eliminating the added weight and texture of traditional methods. This transformation allowed for iconic patterns, like the North Carolina Tar Heels’ argyle side panels, to seamlessly blend with the uniform. The result? Lighter, more durable jerseys that enhanced performance on the court. Sublimation didn’t just change how uniforms looked – it redefined how they were made.

1. Old Uniform Production Methods

Before sublimation became the go-to method, sports uniforms were crafted using techniques like screen printing, heat transfer, embroidery, and tackle twill to add logos and numbers. While these methods got the job done, they came with a host of challenges that impacted performance and design flexibility.

Durability

When it came to durability, sewn-on tackle twill was tough to beat. However, screen-printed designs didn’t hold up nearly as well, often cracking or fading over time. As Cisco Athletic explained:

"Traditional basketball uniforms are heavy with thick fabric and sewn-on lettering. While that type of uniform might have exceptional durability, the truth is that it’s not ideal for athletic performance."

Customization Options

Customizing uniforms back then was a complicated and expensive affair. Screen printing, for example, required a unique setup for each color. This meant that even minor changes – like adding a logo or tweaking a color – would lead to extra costs and longer production times. Design placement was another major limitation. All-over prints or seamless patterns were nearly impossible to achieve with traditional cut-and-sew methods, making it difficult for teams to create personalized designs or accommodate small, unique orders.

Performance Features

The older methods also fell short in terms of performance. Thick fabrics, combined with layered decorations, made uniforms heavy and less breathable. Players often felt the rough textures of dried ink, stitching, or weaves against their skin, which could be distracting and uncomfortable during high-intensity games. While mesh fabrics with 6 to 16 holes per inch provided some ventilation, the added weight from embellishments largely canceled out those benefits.

These drawbacks highlighted the need for a better solution – one that sublimation technology would soon provide.

2. Sublimation Technology

Sublimation transforms ink into gas, which then bonds directly to polyester fibers at high temperatures ranging between 380°F and 420°F. This process has revolutionized athletic apparel, allowing for improved performance on the court and bold, intricate designs.

Durability

One of the standout features of sublimated uniforms is their durability. Unlike traditional printing methods where graphics sit on the fabric’s surface, sublimation embeds the designs into the fibers themselves. This means the graphics won’t crack, peel, or chip over time. As Wooter Apparel highlights:

"The best part is that the numbers, letters, and graphics do not peel, wear off, or come out in the wash!"

Sublimated designs also maintain their vibrancy even after numerous washes and are highly resistant to UV fading. This ensures that jerseys look sharp and retain their details throughout their lifespan.

Customization Options

Sublimation unlocks a world of design possibilities that were previously out of reach. Teams can create all-over prints featuring intricate patterns, gradients, or even photographic images. The process allows for unlimited color options and design placements without increasing costs. Cisco Athletic explains:

"Sublimation also offers unlimited decoration capabilities without raising costs. What does this mean to you? It means that your team can build a jersey with eight colors and 10 design locations without spending an extra cent on the garment!"

Additionally, individual player names and numbers can be easily integrated into the design, as each uniform is printed from its own digital file. Designs are also archived, so teams can replicate their exact look for years to come.

Performance Features

Sublimated uniforms don’t just look great – they also enhance athletic performance. Because the dye is embedded directly into the fabric, the material remains lightweight, with open pores that improve airflow and ventilation. This ensures athletes stay cooler and more comfortable during intense games. The soft texture of the material reduces irritation and chafing, while moisture-wicking properties help keep players dry. Rocky Higgins, Coach and Director of Urban Impact Hoops, shared his appreciation for sublimated jerseys:

"Every tournament we are in, multiple people are coming and talking to us about our jerseys… our kids deserved something special to put on each game."

Cost-Effectiveness

Sublimation also proves to be a smart choice financially, especially for designs with complex graphics. Unlike screen printing, which requires separate setups for each color, sublimation eliminates those additional costs, making it more affordable for smaller production runs. For instance, custom sublimated basketball jerseys at Wooter Apparel typically range from $16.99 to $24.99, with matching shorts starting at $16.99 [website]. The true value shines when teams need multi-colored designs, detailed logos, or all-over patterns – features that would significantly increase costs with traditional methods but are included at no extra charge with sublimation.

sbb-itb-4d95ad3

Pros and Cons

Traditional vs Sublimation Basketball Uniforms Comparison

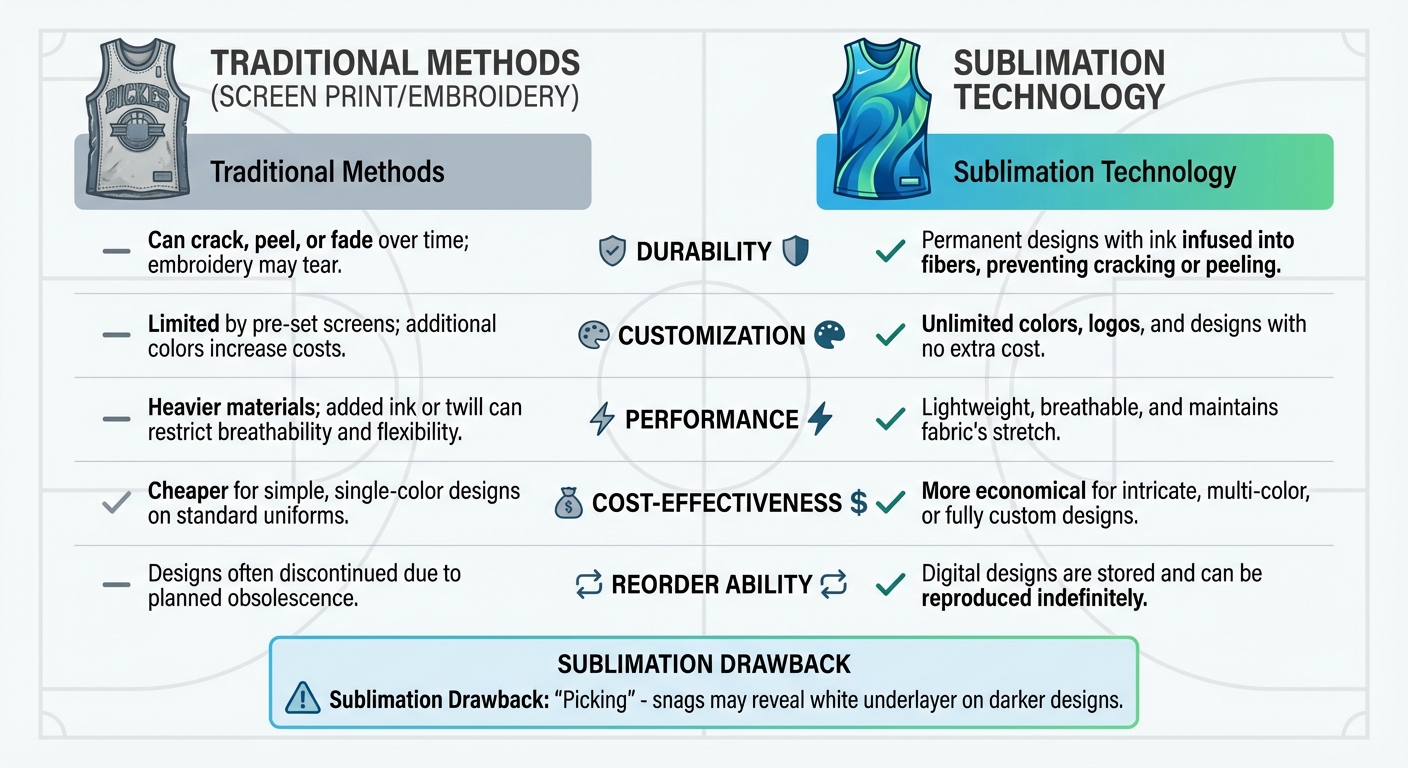

Here’s a comparison between traditional methods and sublimation technology to highlight their key differences:

| Feature | Traditional Methods (Screen Print/Embroidery) | Sublimation Technology |

|---|---|---|

| Durability | Can crack, peel, or fade over time; embroidery may tear | Permanent designs with ink infused into fibers, preventing cracking or peeling |

| Customization | Limited by pre-set screens; additional colors increase costs | Unlimited colors, logos, and designs with no extra cost |

| Performance | Heavier materials; added ink or twill can restrict breathability and flexibility | Lightweight, breathable, and maintains fabric’s stretch |

| Cost-Effectiveness | Cheaper for simple, single-color designs on standard uniforms | More economical for intricate, multi-color, or fully custom designs |

| Reorder Ability | Designs often discontinued due to planned obsolescence | Digital designs are stored and can be reproduced indefinitely |

This comparison underscores how sublimation enhances uniform quality and longevity. While traditional methods might be more economical for basic designs, sublimation offers vibrant, permanent graphics at a consistent cost, regardless of design complexity.

One potential drawback of sublimation is a phenomenon called "picking." If the polyester fabric snags during use, the underlying white base can show through darker designs. Traditional dyed-through fabrics tend to hide such snags more effectively.

However, sublimation eliminates many durability issues associated with traditional methods. As B2W Team Store explains:

"Sublimation literally bonds with the fabric so your design and logo is permanent. Alternate decorations such as silk screening or heat press are applied on top of fabric and will degrade significantly with time and washing."

Additionally, sublimation’s flat-rate pricing ensures costs remain steady, no matter how complex the design. This makes it a cost-effective option for teams looking to maintain vibrant graphics throughout a demanding season.

For teams that prioritize lasting performance and design, sublimation stands out as a modern, reliable solution. At Wooter Apparel, we specialize in fully sublimated, custom uniforms, ensuring teams enjoy unmatched durability and unlimited design possibilities without compromise.

Conclusion

Sublimation technology has reshaped college basketball uniforms by solving issues inherent in older manufacturing techniques. Traditional methods like screen printing and tackle twill often resulted in heavy jerseys that cracked and peeled over time. Sublimation, on the other hand, uses heat – ranging from 380 to 420°F – to bond dye directly with polyester fibers, making the design a permanent part of the fabric itself.

Beyond durability, sublimation also addresses performance concerns. Older methods added unnecessary weight and trapped heat, while sublimated uniforms remain lightweight, breathable, and moisture-wicking – perfect for athletes who need comfort and mobility on the court.

One of the standout features of sublimation is its design flexibility. Teams can create intricate patterns, gradients, and multiple logos without worrying about extra charges for additional colors or designs. Plus, there’s no need for minimum orders, and teams can easily reorder identical designs whenever needed.

Tony Leach, Founder of Prep Ball Stars, highlights this advantage:

"What I appreciate the most about Wooter is the design flexibility. They have brought my designs to life and have even added some flavor of their own."

This combination of durability, performance, and creative freedom makes sublimation the go-to choice for teams aiming to stand out on the court.

At Wooter Apparel, we specialize in fully sublimated custom uniforms that bring these benefits to life. With a 4.9/5 star rating from 1,238 reviews, we’ve helped programs across all levels embrace this game-changing technology.

FAQs

What makes sublimation better than traditional printing methods for basketball uniforms?

Sublimation printing works by embedding ink directly into the fabric, producing colors that are vivid, resistant to fading, and won’t peel over time. Unlike traditional methods like screen printing or vinyl, this technique ensures the colors stay vibrant while keeping the uniforms lightweight, breathable, and soft. This means players get both comfort and top-notch performance on the court.

One standout feature of sublimation is its ability to deliver fully customizable, all-over designs with no limits on color or intricate details. The combination of durability and design flexibility makes sublimation an excellent, budget-friendly choice for teams seeking high-quality uniforms that are built to last.

How does sublimation technology make basketball uniforms better for players?

Sublimation technology works by embedding dye directly into the fabric, resulting in uniforms that are lightweight, breathable, and have a smooth, natural feel. Unlike older printing methods, this approach avoids stiff patches or bulky layers, giving players the freedom to move comfortably on the court.

These uniforms are built to last. Because the colors and designs are bonded into the fabric fibers, they won’t crack, peel, or fade – even after intense gameplay and countless washes. This means athletes can count on their gear to remain flexible, vibrant, and moisture-wicking all season long.

Sublimation offers athletes the ideal mix of comfort, performance, and durability – everything they need to perform at their best in every game.

What are the potential downsides of using sublimation for college basketball uniforms?

While sublimation offers excellent design possibilities and long-lasting results, there are a few drawbacks worth noting. Cost is one of the main considerations – fully sublimated uniforms typically come with a higher initial price compared to options like screen printing or embroidery. Another challenge is that sublimation only works on polyester or polymer-coated fabrics, meaning it’s not suitable for cotton or cotton blends. When used on those materials, designs can appear dull or lack vibrancy.

There’s also the matter of color limitations. Sublimation doesn’t print white ink, so designs look their best on light-colored fabrics. For darker or medium-colored jerseys, a white base layer might be needed to achieve the desired effect. Additionally, the process demands precise heat-press settings. If the temperature or pressure is off, it can lead to problems like fading or color distortion over time. Despite these potential hurdles, Wooter Apparel excels at crafting fully sublimated basketball uniforms that combine performance, style, and durability – helping teams stand out and feel confident on the court.