Sublimation printing has transformed hockey jerseys by offering durable, lightweight, and breathable designs that withstand intense gameplay and repeated washing. Unlike screen printing or embroidery, sublimation embeds dye directly into polyester fabric, ensuring long-lasting graphics that won’t crack, peel, or fade. This process also allows for unlimited colors and full-coverage designs, making it easier for teams to create bold, customized jerseys without adding extra weight or cost.

Key Benefits:

- Durability: Graphics become part of the fabric, resisting wear and tear.

- Lightweight & Breathable: No added bulk, keeping players comfortable.

- Unlimited Customization: Full-color, seamless designs covering every inch.

Wooter Apparel stands out with high-quality polyester jerseys, free design consultations, and transparent pricing starting at $59.99 for small orders, dropping to $34.99 for bulk purchases. Their jerseys combine performance with style, making them a top choice for hockey teams of all levels.

IW Custom Sublimated Hockey Jersey Review

What Is Sublimation Printing

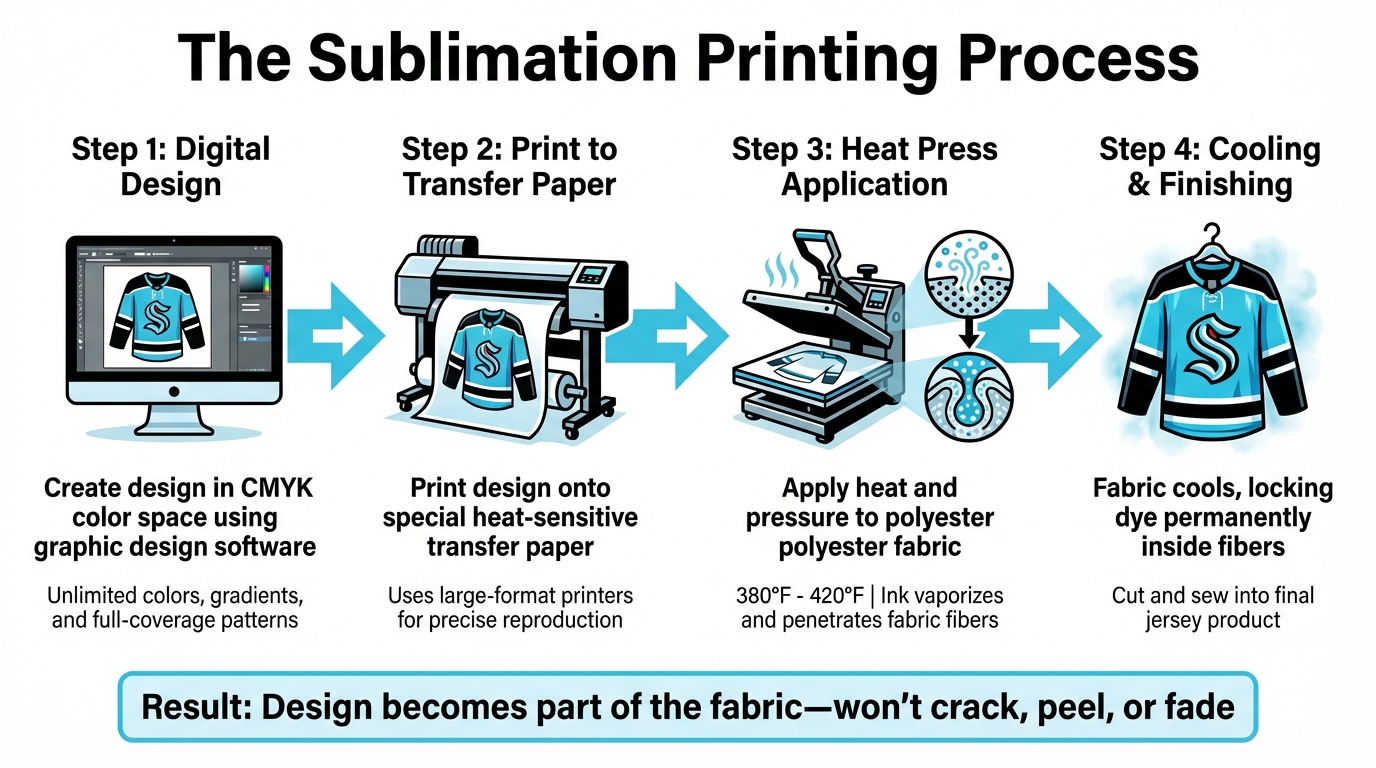

Sublimation Printing Process: 4 Steps from Design to Finished Hockey Jersey

Sublimation printing is a process that uses heat and pressure to infuse dye directly into fabric fibers. This method transforms solid ink into gas – bypassing the liquid phase entirely – at temperatures ranging from 380°F to 420°F. When heated, the pores of polyester fabric open, allowing the dye to penetrate deeply. As the fabric cools, the pores close, permanently locking the dye inside. This results in a design that feels soft and natural, as it becomes part of the fabric itself rather than sitting on the surface like screen printing or embroidery. As The Jersey Generator puts it:

It’s like a tattoo for your jersey – it’s there for good!

Here’s a closer look at how the process works.

The Sublimation Process Step by Step

The sublimation process begins with creating a digital design using graphic design software, typically in the CMYK color space to ensure accurate color reproduction. This method allows designers to use unlimited colors, intricate gradients, and full-coverage patterns without adding extra costs. Once the design is ready, it is printed onto special heat-sensitive transfer paper using large-format printers.

Next, the printed transfer paper is placed on polyester fabric panels and positioned in a heat press set between 380°F and 420°F. Under the heat and pressure, the solid ink vaporizes, and the polyester fibers open up to absorb the dye completely. As the fabric cools, the fibers close, permanently embedding the design. The final step involves cutting and sewing the fabric into the desired product, such as a jersey.

Why Polyester Fabric Works Best

Sublimation printing works only with materials that can absorb the vaporized dye, making polyester the ideal choice. Natural fibers like 100% cotton lack the molecular structure needed to bond with the dye. According to Wooter Apparel:

Sublimation only works on garments made of polyester, or on specialty objects made of polyester or given a polyester coating

Polyester also has moisture-wicking properties that enhance the sublimation process. When heated, its synthetic fibers open up to absorb the dye efficiently. This makes polyester particularly suitable for sportswear, including hockey jerseys, which are manufactured in various polyester weights to meet different needs. For example:

- Pro weight (230 g/m²): Designed for professional, high-impact games.

- Roller Light (160 g/m²): Perfect for recreational hockey.

- Featherweight (120 g/m²): Offers maximum breathability for practice sessions.

This combination of durability, flexibility, and design versatility is why polyester remains the top choice for sublimation printing.

Benefits of Sublimation for Hockey Jerseys

Sublimation offers a range of advantages for hockey teams looking for jerseys that can handle the demands of intense gameplay while maintaining a polished, professional look. These benefits highlight how sublimation elevates traditional hockey jerseys into high-performance gear.

Durability for Game Play

One standout feature of sublimation is its resilience under the physical demands of hockey. Since the dye penetrates the fabric at a molecular level, the graphics are essentially part of the material itself. This means they won’t crack, peel, or flake – even after body checks or regular contact with equipment. As customhockeyuniforms.com puts it:

"Since the dye now permanently resides inside the fibers of the jersey fabric and is not a screen printed ink, vinyl transfer, or sewn appliqué that sits on top, the printing on your jerseys will never fade, crack, peel, or fray."

Once the sublimation process is complete, the dye is locked into the fabric fibers, ensuring the jersey maintains its sharp appearance even after multiple seasons.

| Feature | Sublimation | Screen Printing | Embroidery / Sewn Twill |

|---|---|---|---|

| Durability | Permanent; won’t crack or peel | Prone to cracking and fading | Can fray or pull away from fabric |

| Texture | Soft-hand feel; print not detectable | Thick, rubbery texture on surface | Heavy, bulky, and rigid |

| Breathability | High; fabric pores remain open | Low; ink blocks fabric pores | Low; heavy patches block airflow |

| Weight | Lightweight; no added bulk | Heavier due to ink layers | Heaviest due to thread and patches |

Bright, Long-Lasting Colors

Sublimation delivers vibrant, high-resolution designs that stay bold and colorful, even after repeated washes. The dye deeply embeds into the polyester fibers, ensuring the colors remain bright season after season. Unlike screen printing, which tends to fade over time, sublimation locks the color within the fabric, preserving the jersey’s original vibrancy. This durability ensures the team’s identity remains visually striking throughout the season.

Custom Designs for Team Identity

Sublimation offers unmatched flexibility for creating custom designs without increasing weight or cost. Teams can incorporate intricate striping, logos, names, and numbers in unlimited colors – all seamlessly integrated into the fabric. Tony Leach, founder of Prep Ball Stars, emphasizes this creative freedom:

"What I appreciate the most about Wooter is the design flexibility. They have brought my designs to life and have even added some flavor of their own."

Because the designs are part of the fabric itself, sublimated jerseys avoid the stiff, heavy feel often associated with embroidered patches or screen-printed layers. As noted by the Jersey Generator, sublimated jerseys are "typically lighter and more breathable than traditional jerseys, which can be bulky and heavy from embroidery or screen printing". This added comfort can make a real difference during high-energy games.

sbb-itb-4d95ad3

How Sublimation Improves Team Branding

A strong visual identity is what sets a team apart on the ice. With sublimation, teams can achieve a polished, cohesive look that strengthens their identity. This process digitally embeds designs directly into the fabric, ensuring every jersey perfectly represents the team’s brand. The result? A consistent and professional appearance that also benefits from the durability and vibrant colors mentioned earlier.

Uniformity Across All Jerseys

Sublimation doesn’t just make jerseys durable and colorful – it also ensures that every jersey in the lineup looks identical. By using digital templates, teams can achieve precise color matching and consistent placement of design elements, creating a unified brand image. Plus, with on-demand digital printing, it’s easy to order replacement jerseys or create new ones for additional players that perfectly match the originals.

Endless Design Possibilities

Sublimation offers teams a creative edge. The process supports an unlimited range of colors, including bold neons, striking gradients, and electric accents that maintain their vibrancy wash after wash. Every inch of the jersey – from the front and back to the sleeves – can be customized. Teams can incorporate photorealistic images, detailed logos, sponsor patches, and player names directly into the fabric, delivering a seamless design.

Beyond the graphics, customization extends to trims, necklines, and shoulder designs, allowing teams to craft jerseys that truly reflect their personality. For an extra touch, specialty finishes such as rhinestones or foil can be added through heat transfer, giving jerseys a standout look on and off the ice.

Why Choose Fully Sublimated Jerseys from Wooter Apparel

Wooter Apparel takes the advantages of sublimation technology and combines them with expert craftsmanship to create high-performance hockey jerseys that shine both on and off the ice. With a stellar 4.9/5 rating from over 1,238 reviews, Wooter stands out by offering top-notch materials, advanced customization, and excellent customer service.

Premium Materials and Custom Design Services

Wooter uses 100% polyester fabrics designed to bond seamlessly with sublimation dyes, ensuring durability and vibrant colors that last. These jerseys are built for performance, featuring dry-fit, moisture-wicking, and breathable properties to keep players cool and comfortable during intense games. Unlike traditional printing methods, sublimation eliminates heavy layers of ink, resulting in lightweight jerseys that feel soft and allow unrestricted movement on the ice.

Need help with your design? Wooter’s in-house design team offers free consultations to bring your ideas to life. Whether you have a fully developed concept or just a rough idea, their designers collaborate with you to create custom artwork that captures your team’s personality.

Reliable Delivery and Outstanding Support

Wooter keeps things moving with a standard delivery time of 3 to 4 weeks, and rush orders can be completed in as little as 2 to 3 weeks. They even back their delivery promise with a partial refund if they miss the one-month deadline. Their customer support team is available 24/7 via live chat and by phone Monday through Friday (10:00 AM to 8:00 PM EST). Customers often praise team members like Olga, Jeremy, and Mark for their consistent communication and helpfulness throughout the process.

Endless Customization at Transparent Prices

Wooter offers unlimited customization options, including colors, gradients, and patterns, all included in the base price. Player names and numbers? No extra charge. Pricing starts at $59.99 for orders of 10 to 50 jerseys, drops to $49.99 for 101 to 250 jerseys, and goes as low as $34.99 for bulk orders over 1,000. Custom hockey socks are also available, ranging from $22.99 per pair for smaller orders to $11.99 for bulk quantities over 1,000 pairs. This flexible pricing ensures teams of all sizes – from youth leagues to adult recreational groups – can access professional-quality jerseys without breaking the bank.

Conclusion

Sublimation embeds dye directly into jersey fabric, ensuring designs that won’t crack, peel, or fade. This process produces vibrant, lasting colors and sharp details that can handle intense gameplay and countless washes without losing their appeal.

What sets sublimation apart is its limitless design potential. Teams can incorporate intricate gradients, photographic images, and full-coverage prints across the entire jersey – without worrying about extra costs. Plus, sublimation delivers a lightweight, breathable finish that athletes appreciate, making it a practical choice for performance wear. These design options help teams create a cohesive and standout identity, whether they’re on the ice or off.

Wooter Apparel takes full advantage of sublimation’s benefits, combining high-quality polyester with expert craftsmanship to produce durable and eye-catching jerseys. They offer free design consultations and ensure delivery within 3 to 4 weeks, earning a stellar 4.9/5 rating from over 1,238 reviews. Their straightforward pricing structure makes it easy for teams of any size to find the right fit.

On top of all that, sublimation is an environmentally conscious process, generating zero waste and using no water. For teams looking for jerseys that balance durability, creative freedom, and comfort, fully sublimated uniforms from Wooter Apparel are an excellent choice for today’s hockey players.

FAQs

What makes sublimation printing more durable than traditional screen printing?

Sublimation printing works by embedding the ink directly into the polyester fibers of the fabric. This process makes the design a permanent part of the material, ensuring it won’t crack, peel, or fade – even after repeated washing and wear.

On the other hand, traditional screen printing applies ink onto the surface of the fabric. While this method can work well for certain applications, screen-printed designs are more likely to crack, peel, or fade over time, especially as the fabric stretches or ages. For high-performance team jerseys, sublimation provides a more durable and vibrant option.

Why is polyester the best fabric for sublimation printing on hockey jerseys?

Polyester stands out as the ideal fabric for sublimation printing due to its heat-responsive fibers, which enable the dye to fuse directly with the material. This results in bright, durable colors that resist fading, even after heavy use and repeated washing.

Beyond its printing advantages, polyester is lightweight, moisture-wicking, and incredibly tough – perfect for hockey jerseys. These features help players stay dry and comfortable on the ice while ensuring their uniforms maintain a polished, professional appearance.

What are the customization options for hockey jerseys with sublimation printing?

Sublimation printing gives hockey teams the chance to design jerseys that are completely their own. Whether it’s bold gradients, intricate graphics, or unlimited color combinations, every detail becomes part of the fabric itself, creating a finish that’s both vibrant and durable. Want to include your team’s logo, a mascot, or even custom artwork? No problem – these can be added at no extra cost. Plus, every part of the jersey, from the sleeves and collars to the socks, can be tailored to bring your vision to life.

You can also add a personal touch for each player. Names and numbers are printed directly onto the jersey, and you get to decide the font style, size, and placement to match your team’s style – all included in the price. The process is straightforward: enjoy a free design consultation, receive quick mock-ups, and benefit from a clear timeline. The result? High-quality jerseys that are as unique as your team and guaranteed to make an impression on the ice.