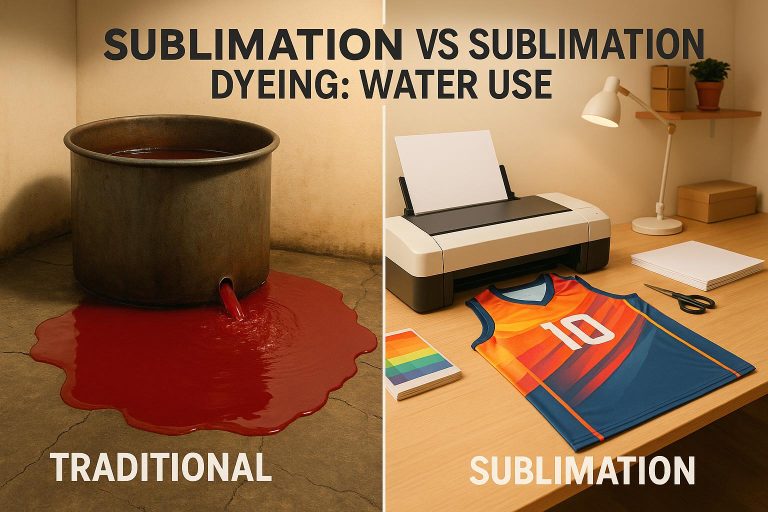

Sublimation printing drastically reduces water usage compared to dyeing methods that rely heavily on water. While dyeing can consume up to 200 liters of water per kilogram of fabric, sublimation uses only 5 milliliters. This significant reduction eliminates wastewater and chemical runoff, making sublimation a cleaner choice.

Key points:

- Dyeing uses water for pre-treatment, dye baths, and rinsing, generating polluted wastewater.

- Sublimation embeds ink into fabric using heat, skipping water-heavy steps.

- Sportswear, often made from polyester, benefits greatly from sublimation due to its efficiency and durability.

Quick Comparison:

| Factor | Dyeing (Liters/kg) | Sublimation (ml/kg) | Impact |

|---|---|---|---|

| Water Use | 100–200 | 5 | Sublimation uses 40,000x less water |

| Wastewater Produced | High | None | Sublimation avoids water pollution |

| Chemical Use | High | Minimal | Sublimation reduces harmful runoff |

Switching to sublimation for designs, especially in sportswear, aligns with water-saving goals while maintaining quality and longevity.

How Sublimation Printing Uses Water

The Sublimation Printing Process

Sublimation printing works in a way that’s quite different from traditional dyeing techniques. It starts with a digital print of the design on transfer paper, using sublimation inks. These inks are unique because they skip the liquid phase entirely – when heated, they go straight from solid to gas.

The magic happens when heat and pressure come into play. The transfer paper is placed on polyester fabric and pressed at about 400°F (204°C) for 45–60 seconds. During this time, the ink turns into a gas, penetrates the polyester fibers at a molecular level, and bonds as the fabric cools. The result? A permanent, vibrant design embedded into the material.

What sets sublimation apart is its waterless approach. Unlike traditional dyeing, which involves multiple washing, rinsing, and chemical processes, sublimation relies solely on heat to transfer the dye. There’s no need for pre-treatment or post-dyeing washes, which drastically reduces water usage.

Another advantage is precision. Sublimation uses exactly the amount of dye needed – there’s no excess to wash away. This not only ensures bold, long-lasting designs but also contributes to the process’s water-saving nature.

Water-Saving Benefits of Sublimation

Sublimation printing’s efficiency makes it a standout choice for conserving water. Compared to traditional methods, its environmental advantages are clear. As AllPrintHeads highlights:

"Sublimation printing does not need either water or toxic chemicals to print, making it a much more sustainable option compared to traditional methods".

One of its greatest strengths is the complete elimination of wastewater. Traditional dyeing often generates polluted water filled with harmful chemicals, requiring expensive treatment before disposal. This wastewater can have serious effects on local ecosystems. Sublimation avoids these problems entirely by removing water from the equation, preventing chemical runoff and pollution.

These eco-friendly benefits make sublimation especially appealing for custom sportswear. Sports organizations and schools, often focused on sustainability, find it aligns with their goals. Plus, sublimation works seamlessly with polyester and synthetic blends – fabrics that are popular for athletic wear due to their moisture-wicking and performance-enhancing properties.

Water Use in Traditional Dyeing Methods

How Traditional Dyeing Works

Traditional dyeing methods depend heavily on water through every step of the process. Unlike the heat-driven sublimation printing technique, these traditional approaches require large amounts of water to dissolve dyes, penetrate fibers, and wash away excess chemicals.

The process starts with pre-treating fabrics by soaking them in water-based solutions to prepare the material for dye absorption. Afterward, textiles are submerged in large vats containing water, dyes, and other chemicals to ensure even saturation and color distribution. Some common techniques include:

- Vat dyeing: Cotton fabrics are immersed in heated water baths and go through repeated rinsing cycles.

- Reactive dyeing: This method forms chemical bonds between dye and fiber molecules, requiring multiple washing stages to remove unreacted dyes and salt residues.

- Direct dyeing: Dyes are applied directly to wet fabric in water baths, though this still involves significant water usage for preparation, application, and post-dyeing cleanup.

On average, dyeing and finishing processes can use up to 125 liters of water per kilogram of cotton. This extensive water usage creates a foundation for serious environmental challenges.

Environmental Problems with Traditional Dyeing

Traditional dyeing isn’t just water-intensive – it also creates enormous amounts of polluted wastewater. For every ton of dyed fabric, up to 200 tons of wastewater may be generated. This wastewater is filled with harmful substances like dyes, heavy metals, chemical salts, and other byproducts that can linger in the environment for years.

As Alchemie Technology points out:

"Traditional textile dyeing processes are among the most water-intensive in the textile supply chain – using up to 93 billion cubic metres of water annually and contributing 20% of global industrial wastewater".

This heavy reliance on water has profound consequences for local ecosystems. Textile dyeing is the second-largest global contributor to water pollution, with the fashion industry alone responsible for about 20% of worldwide water contamination. For instance, reactive dyes in cotton mill effluent have been measured at concentrations as high as 800 mg/L, while Acid Orange levels in some fabric plant wastewater have reached 45 mg/L. These pollutants increase the chemical oxygen demand in water bodies, depleting oxygen levels that aquatic life depends on. Additionally, dyes can block sunlight, which inhibits photosynthesis in algae and aquatic plants, disrupting the entire food chain and leading to biodiversity loss. Over time, these toxins can also harm human health, causing oxidative stress and damage to multiple organs.

The environmental toll doesn’t stop there. Washing dyed textiles releases microplastics, adding another layer of harm to aquatic ecosystems.

Given this stark environmental impact, water-free technologies like sublimation printing offer a much-needed alternative. This is especially relevant for industries like custom sportswear production, where both performance and environmental responsibility are key priorities.

Water Use Comparison: Sublimation vs Traditional Dyeing

Water Use and Environmental Impact Table

The contrast in water usage between traditional dyeing and sublimation printing is striking. Traditional dyeing methods consume anywhere from 100 to 200 liters of water per kilogram of fabric, while sublimation printing requires just 5 milliliters – a difference of up to 40,000 times less water.

| Environmental Factor | Traditional Dyeing | Sublimation Printing | Relative Benefit |

|---|---|---|---|

| Water Usage per kg of fabric | 100–200 liters | 5 milliliters | Approximately 40,000x less water |

| Wastewater Generation | Excessive, chemically laden wastewater | Negligible wastewater | Nearly eliminates wastewater |

| Chemical Usage | Heavy use of auxiliary chemicals | Primarily water-based inks | Substantial reduction |

| Global Water Pollution Impact | Contributes 17–20% of industrial water pollution | Negligible impact | Essentially eliminates pollution |

| Ink Efficiency | Standard consumption | Uses only about 10% of the ink required for screen printing | About 90% less ink usage |

Traditional dyeing not only consumes vast amounts of water but also generates significant amounts of chemically contaminated wastewater. On the other hand, sublimation printing uses heat to transfer colors, bypassing the need for water baths and virtually eliminating wastewater production.

These findings highlight the urgent need for water conservation efforts in the U.S. textile industry.

U.S. Water Conservation Standards

The dramatic differences in water consumption emphasize the importance of sustainable practices in the textile sector. In the U.S., stricter water conservation standards are pushing manufacturers toward more environmentally friendly production methods. With the global textile and apparel industry using approximately 93 billion cubic meters of water annually, domestic manufacturers are under increasing pressure to cut water usage and comply with stringent wastewater regulations.

Federal and state policies require textile facilities to adopt water recycling systems and meet strict discharge standards. For instance, California’s advanced water conservation regulations have prompted many manufacturers to explore water-free technologies like sublimation printing. This method not only aligns with the EPA’s pollution prevention goals but also helps businesses adhere to evolving requirements under the Clean Water Act‘s National Pollutant Discharge Elimination System (NPDES). As regulations tighten, efficient, water-saving techniques like sublimation printing are becoming essential for companies aiming to meet environmental and regulatory benchmarks.

sbb-itb-4d95ad3

Dye-Sublimation vs. Water-based Screen Printing – What’s the Difference? 🤔

Water Use Impact on Custom Team Uniforms

The way custom team uniforms are produced can have a big impact on water conservation across the United States. With millions of sports teams ordering new uniforms every year, the choice of production methods – like traditional dyeing versus sublimation printing – plays a key role in shaping how much water is used in the process. This opens up a broader conversation about how material selection and production techniques influence the environmental footprint of sportswear.

Why Polyester Dominates Custom Sportswear

Polyester is the go-to fabric for custom team uniforms, and for good reasons. This synthetic material is lightweight, durable, and great at wicking moisture away from the body, keeping athletes dry and comfortable during games. Unlike cotton, which absorbs sweat and can feel heavy, polyester holds its shape and performs well under the demands of athletic competition.

Traditional dyeing methods, however, require large amounts of water to properly color synthetic fabrics like polyester. This is where sublimation printing stands out. Sublimation doesn’t rely on water baths and avoids many of the challenges that come with traditional dyeing. Instead, it uses heat to transfer dye directly into the fabric, making it an ideal choice for high-performance sportswear.

"In addition to its excellent visual and technical qualities, sublimation printing also stands out for its lower environmental impact. The process uses no water – unlike traditional printing methods – and does not produce chemical waste."

– Silvia Kabaivanova, Founder of Be Global Fashion Network

Sublimation also offers cost advantages. Teams can reuse design elements and add sponsor logos without extra charges, making it easier to create high-quality uniforms that are both budget-friendly and environmentally conscious.

Meeting Environmental Goals with Sublimation

Sports organizations across the country are increasingly focused on reducing their environmental impact, and the way uniforms are made plays a critical role in achieving these goals. Sublimation printing is an effective way for teams to cut down on their water usage while still delivering vibrant, durable designs.

For example, a typical basketball uniform package weighs about 2.2 pounds (1 kilogram). Producing this package using traditional methods can consume up to 53 gallons of water. Sublimation, on the other hand, nearly eliminates water use, offering a much more sustainable alternative.

Companies like Wooter Apparel highlight the benefits of sublimation by specializing in fully sublimated uniforms for sports like basketball, football, and soccer. Their process avoids the heavy water use tied to traditional dyeing while delivering affordable options – custom jerseys start at just $16.99. By combining cost efficiency with sustainability, Wooter Apparel proves that eco-friendly choices don’t have to break the bank.

Teams can take sustainability even further by choosing recycled polyester (rPET) fabrics for their sublimated uniforms. This pairing – water-free printing and recycled materials – addresses both water conservation and plastic waste reduction in sportswear.

For athletic directors, the potential water savings are impressive. A high school with 20 sports teams ordering new uniforms could save over 1,000 gallons of water annually by switching to sublimation printing. Plus, sublimated designs are long-lasting. Unlike screen printing or heat transfers, which can crack or fade, sublimation creates permanent designs that stay vibrant for the life of the fabric. This durability reduces the need for frequent replacements, cutting down on waste and resource use over time.

Conclusion

Sublimation printing offers a smart alternative to traditional dyeing by drastically cutting down water use and reducing its impact on the environment. Unlike traditional dyeing, which relies on large amounts of water for dye baths and rinsing, sublimation printing requires virtually no water during the dyeing process. This approach can reduce water usage by as much as seven times when applied to solid-color designs. These savings not only help protect natural resources but also align with the growing demand for eco-friendly practices in the sportswear industry.

The advantages go beyond water conservation. Traditional dyeing methods often generate polluted wastewater, leading to costly treatments and increased risks of water contamination. Sublimation printing eliminates this issue entirely with its waterless process, resulting in a cleaner and more efficient production cycle.

For sports teams across the country, adopting sublimation printing means more than just supporting environmental goals – it also brings practical benefits. With its ability to deliver high-performance sportswear, this method ensures athletes can excel while teams reduce their environmental footprint. It’s a win-win for both the planet and the players.

On top of the environmental perks, sublimation printing offers financial advantages. For instance, Wooter Apparel demonstrates how sustainable practices can remain affordable, with custom jerseys starting at just $16.99. As organizations like the Sustainable Apparel Coalition continue to stress the importance of water-efficient textile production, sublimation printing positions itself as the responsible and cost-effective choice for custom sportswear in the United States.

FAQs

Why is sublimation printing more environmentally friendly than traditional dyeing methods?

Sublimation printing stands out as a greener option compared to traditional dyeing methods, primarily because it doesn’t require water during the printing process. This not only slashes water usage but also prevents pollution from dye runoff, which can contaminate waterways.

What’s more, sublimation relies on water-based inks that steer clear of harmful solvents and volatile organic compounds (VOCs). This means less chemical waste and a reduced environmental footprint. By combining vibrant, durable designs with a more planet-friendly approach, sublimation printing offers a smarter way to create while keeping environmental concerns in mind.

What makes sublimation printing a better option for sportswear in terms of performance and durability?

Sublimation printing is a go-to choice for sportswear because it produces bold, durable designs that hold up against heavy use and repeated washing. The process embeds the ink directly into the fabric fibers, ensuring the colors remain sharp and vibrant over time without fading or peeling.

Another big advantage? It keeps the fabric’s breathability and flexibility intact – both essential for athletic performance. Unlike traditional printing methods, sublimation doesn’t add extra weight or interfere with the material’s natural stretch. This makes it perfect for activewear that needs to handle intense workouts while staying comfortable and tough.

How does sublimation printing support water conservation efforts in the U.S. textile industry?

Sublimation printing skips the need for water entirely, offering a cleaner alternative to traditional dyeing methods that typically consume large quantities of water. By removing water from the equation, sublimation printing not only reduces waste but also aligns with U.S. water conservation goals and regulatory standards.

Unlike traditional dyeing, which faces strict regulations to curb water pollution and overuse, sublimation printing sidesteps these challenges altogether. This makes it a smart choice for textile production, especially as the industry leans toward greener practices to tackle water shortages and rising expenses.