Gradient jerseys are popular for their smooth color transitions, but creating durable and visually striking designs can be tricky. Sublimation printing solves these challenges by embedding dye directly into polyester fabric, ensuring long-lasting, lightweight, and breathable jerseys. Unlike other methods, sublimation avoids cracking, peeling, or fading, while delivering seamless gradients and vibrant colors. Here’s why sublimation stands out:

- No Cracking or Peeling: The design becomes part of the fabric, not just a surface layer.

- Smooth Color Transitions: Sublimation achieves flawless gradients without banding or pixelation.

- Lightweight and Breathable: Jerseys retain their moisture-wicking and cooling properties.

- Durable Design: Colors stay intact even after stretching, washing, and heavy use.

Sublimation is ideal for teams looking for bold, professional designs that perform well on the field. Pairing this method with high-polyester fabrics ensures jerseys remain game-ready all season.

All Over Print Jersey – How It’s Made [intotheam.com]

Problems With Traditional Printing Methods for Gradient Jerseys

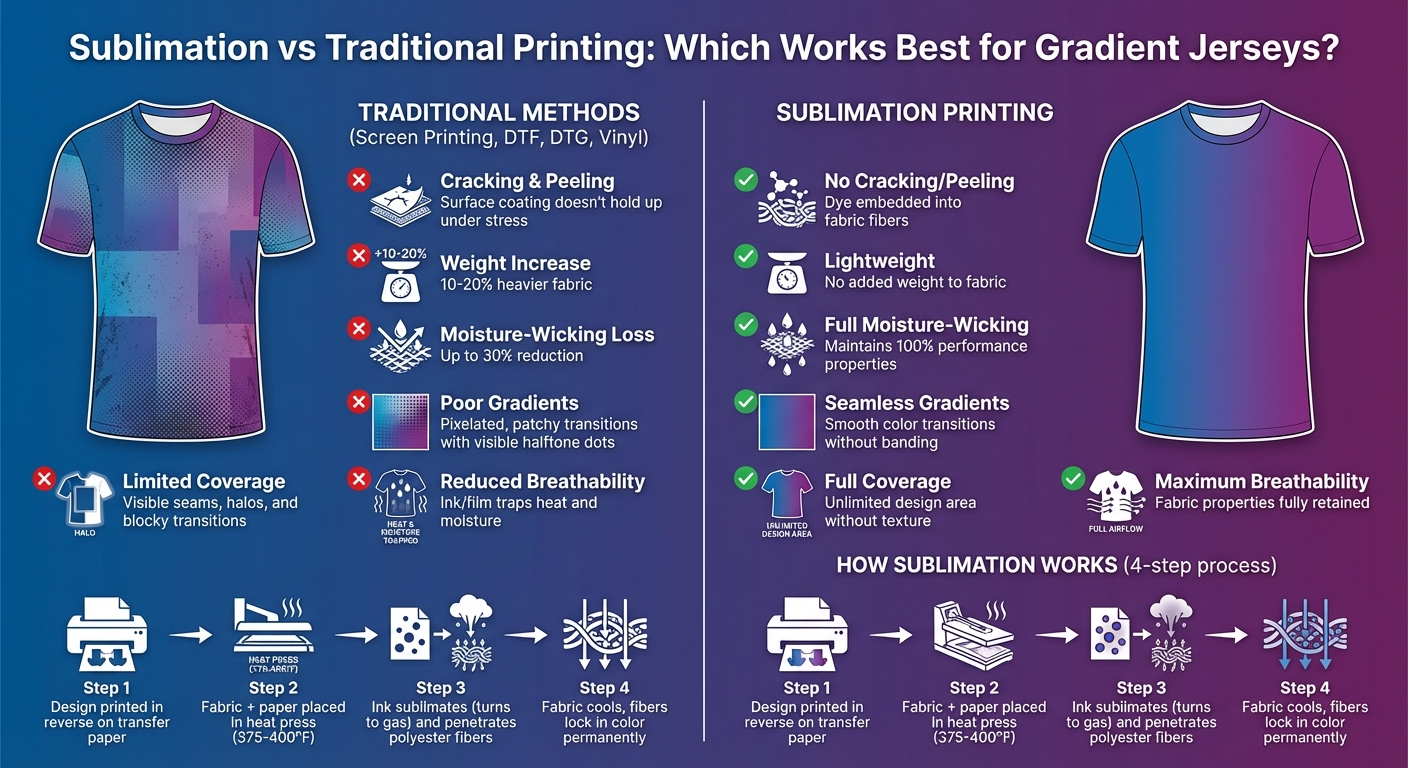

Sublimation vs Traditional Printing Methods for Gradient Jerseys

Building on the challenges discussed earlier, traditional printing methods bring additional hurdles when it comes to creating gradient jerseys. These methods often compromise both the durability and the visual appeal of the finished product.

Surface Printing Causes Cracking and Peeling

Techniques like screen printing, vinyl application, DTF, and DTG all involve layering ink or film on top of the fabric. This creates a surface coating that doesn’t hold up well under stress. Over time, stretching, washing, and regular wear lead to cracking, peeling, and flaking. Areas that experience frequent movement, like shoulders and underarms, are especially prone to this damage because of the constant flexing of the material.

Gradients add to this problem because they require more extensive ink coverage compared to simple logos or text. What might start as a bold and smooth fade can quickly degrade into a patchy, uneven design – leaving the jersey looking worn out and unprofessional.

Limited Color Range and Uneven Transitions

Traditional printing methods also struggle to produce the smooth, seamless transitions that make gradients visually appealing. Screen printing, for example, requires separate screens for each color, and achieving a gradient effect means relying on halftone techniques. The result? Coarse, pixelated transitions that fall short of professional standards.

DTF printing faces similar difficulties because it depends on precise ink densities, which don’t translate well for gradients. The outcome often looks patchy or uneven. DTG printing on darker fabrics presents additional challenges, as it requires a white underbase to make colors pop. This underbase can create visible halos, outlines, or awkward rectangular shapes beneath the gradient areas. Vinyl heat transfer fares no better – layering multiple colors to mimic gradients leads to visible seams and blocky transitions, making smooth fades nearly impossible.

These limitations not only affect the design’s appearance but also reduce the overall functionality of the jersey.

Reduced Comfort and Breathability

Athletes need jerseys that keep them cool and comfortable during intense activity, but traditional printing methods often hinder these essential qualities. Adding ink or film to the fabric increases the garment’s weight by 10-20% and can reduce its moisture-wicking ability by as much as 30%. These printed areas trap heat and moisture against the skin, making the jersey feel heavy and uncomfortable.

For gradient jerseys, which often feature large, continuous design areas across the chest and back, these drawbacks become even more pronounced. Significant portions of the uniform lose their athletic performance, leaving players to wear jerseys that might look impressive but feel restrictive and stifling during the game.

Why Sublimation Printing Works Best for Gradient Jerseys

Sublimation printing solves many of the challenges that come with traditional methods. Instead of layering ink or film on the surface of the fabric, sublimation embeds the color directly into the material itself. This approach creates those smooth, vibrant gradients that baseball and softball teams love, all while maintaining the jersey’s durability and performance. Let’s break down how this process works.

How Sublimation Printing Works

Sublimation printing uses heat and pressure to turn solid dye into gas, which then bonds permanently with polyester fibers – a popular material for performance jerseys. Here’s how it happens:

- A full-color design is printed in reverse onto special transfer paper using sublimation inks.

- The fabric and transfer paper are placed into a heat press set between 375–400°F.

- At these high temperatures, the ink sublimates (turns into gas) and penetrates the fibers of the fabric.

- Once the fabric cools, the fibers close around the dye, locking in the colors permanently.

The result? A design that becomes part of the jersey itself, not just a layer sitting on top. This process ensures seamless color transitions – no pixelation, banding, or halftone dots. Unlike screen printing or some DTF methods, sublimation creates gradients that flow effortlessly across the entire jersey, from the chest to the back and even across sleeves and side panels.

Benefits of Sublimation for Gradient Designs

Sublimation is perfect for creating intricate, multi-color gradients with precision. This method allows for full-coverage designs without adding extra weight or texture to the jersey. Teams can achieve bold fades that extend from the collar to the hem or wrap around the sleeves. You can even blend multiple colors seamlessly – something traditional printing methods struggle to replicate.

The colors are consistently vibrant and accurate, ensuring every jersey looks sharp and professional. Plus, because the dye becomes part of the fabric, the material retains its natural lightness, breathability, and moisture-wicking properties. This means players stay cool and comfortable, even during long games. These advantages make sublimation the go-to choice for teams looking for both standout designs and performance.

Better Durability and Performance

Sublimated jerseys are built to last. The colors won’t crack, peel, or flake because they’re embedded directly into the fabric. Whether the jersey is stretched, flexed, or washed repeatedly, the design stays intact and vibrant – from opening day all the way through championship season.

Wooter Apparel specializes in creating fully sublimated uniforms that combine durability, performance, and style. Their jerseys help teams across the United States look polished and professional while performing at their best on the field.

sbb-itb-4d95ad3

Design Tips for Gradient Baseball and Softball Jerseys

Selecting the Right Fabric

When it comes to creating vibrant gradient jerseys, choosing the right fabric is absolutely essential. Polyester is the go-to material here – sublimation printing works best when the fabric contains at least 65–80% polyester. Anything less, and you risk ending up with dull or washed-out colors. For baseball and softball teams, fabrics with 100% polyester or high-polyester blends are ideal. Why? They’re lightweight, wick moisture effectively, and allow for breathability, keeping players comfortable throughout the game.

For the best results, stick to a smooth, matte finish. This helps avoid light reflections that might make the gradients appear patchy on the field. Also, always start with a white or very light base color. Sublimation dyes are transparent, so they need that light background to really pop. Using dark base fabrics can flatten the gradient effect and make the colors appear muted. Lastly, ensure the fabric weight is consistent across all uniform pieces – whether home or away jerseys or even different sizes. This consistency ensures the gradients look uniform under stadium lights and in team photos.

Once you’ve nailed the fabric, the next step is seamlessly blending gradients with your team’s branding.

Combining Gradients With Team Branding

Team branding and gradients can work beautifully together, but it’s all about balance. A key priority is ensuring numbers and names are easy to read, especially since most leagues in the U.S. require player numbers to be clearly visible from a distance. To achieve this, place numbers and team names over solid color areas – either at the top or bottom of the jersey – rather than over the gradient’s transition zone. For example, dark navy numbers look great on lighter gradients, while white numbers stand out on darker fades.

Adding an outline in a contrasting color around the numbers can further enhance visibility. For team logos and other branding elements, position them in "quiet zones", which are areas of solid or gently transitioning colors. Meanwhile, you can apply more intricate gradient effects to areas like sleeves, side panels, or the lower torso. This approach not only ensures compliance with league rules but also creates a jersey design that’s visually striking and functional. Companies like Wooter Apparel specialize in turning team ideas into custom gradient uniforms that strike the perfect balance between bold design and on-field practicality.

Caring for Sublimated Jerseys

To keep those vivid gradients looking sharp all season, proper care is a must. Sublimated colors are durable, but they’ll last even longer with the right maintenance. Wash jerseys in cold water using a mild detergent, and steer clear of bleach or fabric softeners. Turning the jerseys inside out before washing can help minimize wear and tear.

When it’s time to dry, air drying is the safest option, but you can also tumble dry on low heat. Avoid high temperatures, as they can weaken the polyester fibers and slightly alter the jersey’s fit over time. Never iron directly on the fabric, and don’t leave damp uniforms crumpled in equipment bags – this can lead to bacterial growth and bad odors. Instead, hang jerseys to air out after games and store them clean, dry, and on hangers to preserve their original brightness and fit.

Conclusion

When it comes to designing gradient jerseys for baseball and softball teams, sublimation printing is hard to beat. This method embeds dye directly into polyester fabric, creating smooth color transitions and vivid designs that other printing techniques just can’t replicate. Unlike screen printing or heat transfer, which can crack, peel, or fade, sublimated designs become part of the fabric itself – ensuring they look sharp and professional, even after countless games and washes.

But it’s not just about the look. Performance matters, especially for athletes playing in the heat of U.S. summers. Since sublimation doesn’t add extra layers of ink, these jerseys stay lightweight, breathable, and moisture-wicking – features that are essential for keeping players cool and focused on the field.

The results speak for themselves. Teams aiming to stand out on the diamond benefit from sublimation’s durability, vibrant colors, and performance. Companies like Wooter Apparel make it easy to bring custom designs to life, offering fully sublimated gradient jerseys along with free design services. With over 2,000 five-star reviews and a 4.9-star rating, it’s clear their customers appreciate the quality and style of their uniforms.

For jerseys that combine striking designs with long-lasting comfort, sublimation is the way to go. It’s a game-changer for teams looking to elevate their look and performance.

FAQs

How does sublimation printing keep jerseys breathable?

Sublimation printing works by infusing ink directly into the fabric’s fibers instead of layering it on top. This technique helps jerseys stay lightweight and breathable, allowing air and moisture to pass through easily. The result? Athletes stay cool and comfortable, even during intense gameplay.

Why is sublimation the best choice for gradient designs on jerseys?

Sublimation is a standout choice for gradient designs, delivering smooth and vibrant color transitions that traditional printing methods often can’t match. Instead of sitting on the surface like screen printing or heat transfers, sublimation embeds the ink directly into the fabric. This ensures the design remains bright, seamless, and resistant to fading, cracking, or peeling, even with frequent use.

Another big advantage is the freedom to use unlimited colors, making it ideal for complex gradients and bold, custom designs. The end product? A professional-looking jersey that can handle the demands of sports and repeated washing without losing its appeal.

Why is polyester the best fabric for sublimation printing on jerseys?

Polyester stands out as the best fabric for sublimation printing because it lets the dye bond directly with its fibers. This results in vivid, durable designs that resist fading, cracking, or peeling, even after countless washes or heavy use.

On top of that, polyester is lightweight and wicks away moisture, making it an excellent choice for athletic jerseys. It keeps players comfortable while displaying bold designs that last.