Smart sublimation equipment is transforming sportswear production. These machines combine dye sublimation printing with automation, IoT features, and advanced software to deliver faster production, better design precision, and reduced waste. Key highlights include:

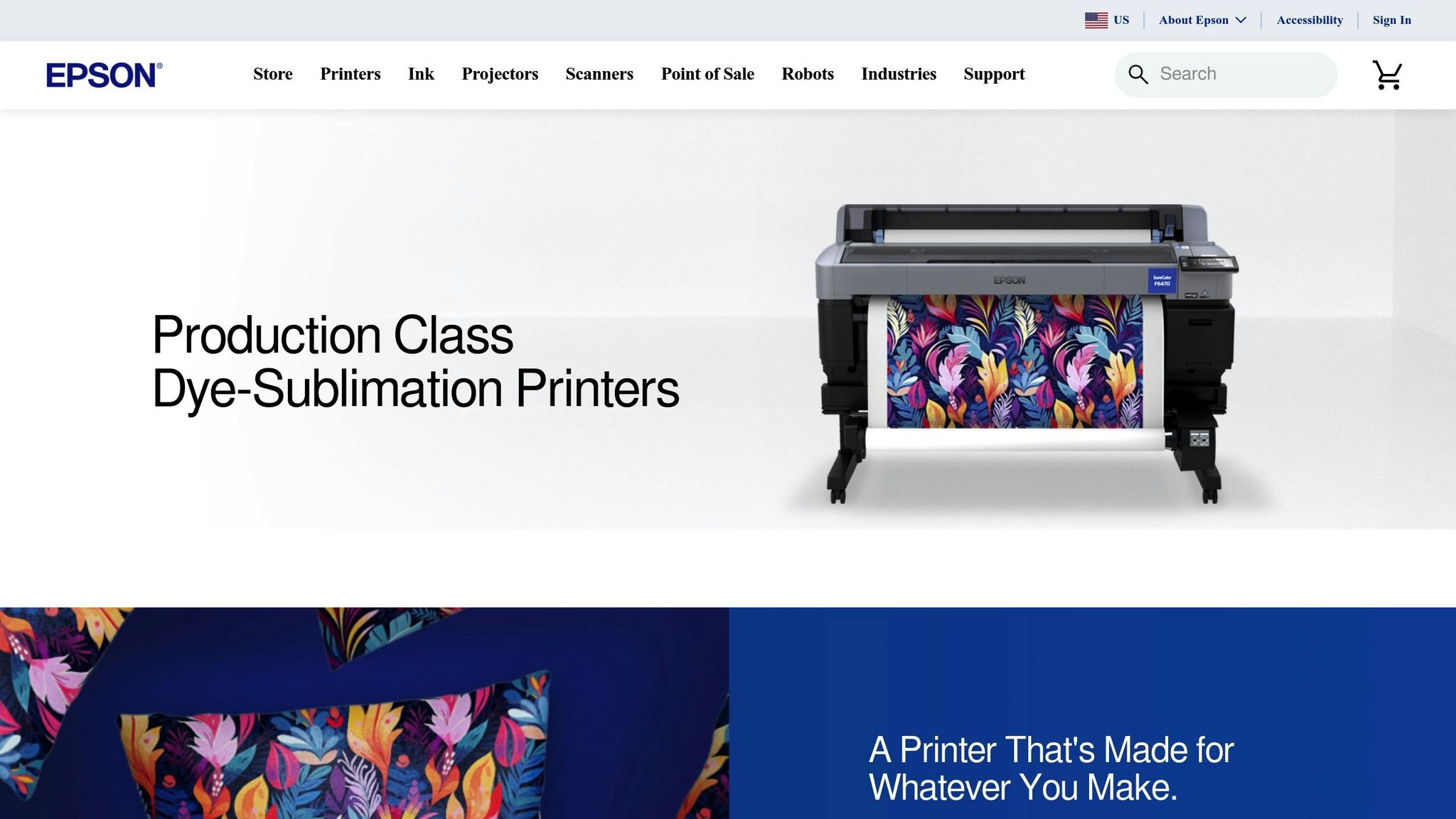

- Epson SureColor F-Series: High-speed printers with cloud monitoring and precise color output for large-scale production.

- Sawgrass Virtuoso SG1000: Compact, user-friendly, and ideal for polyester-rich fabrics, offering sharp, durable prints.

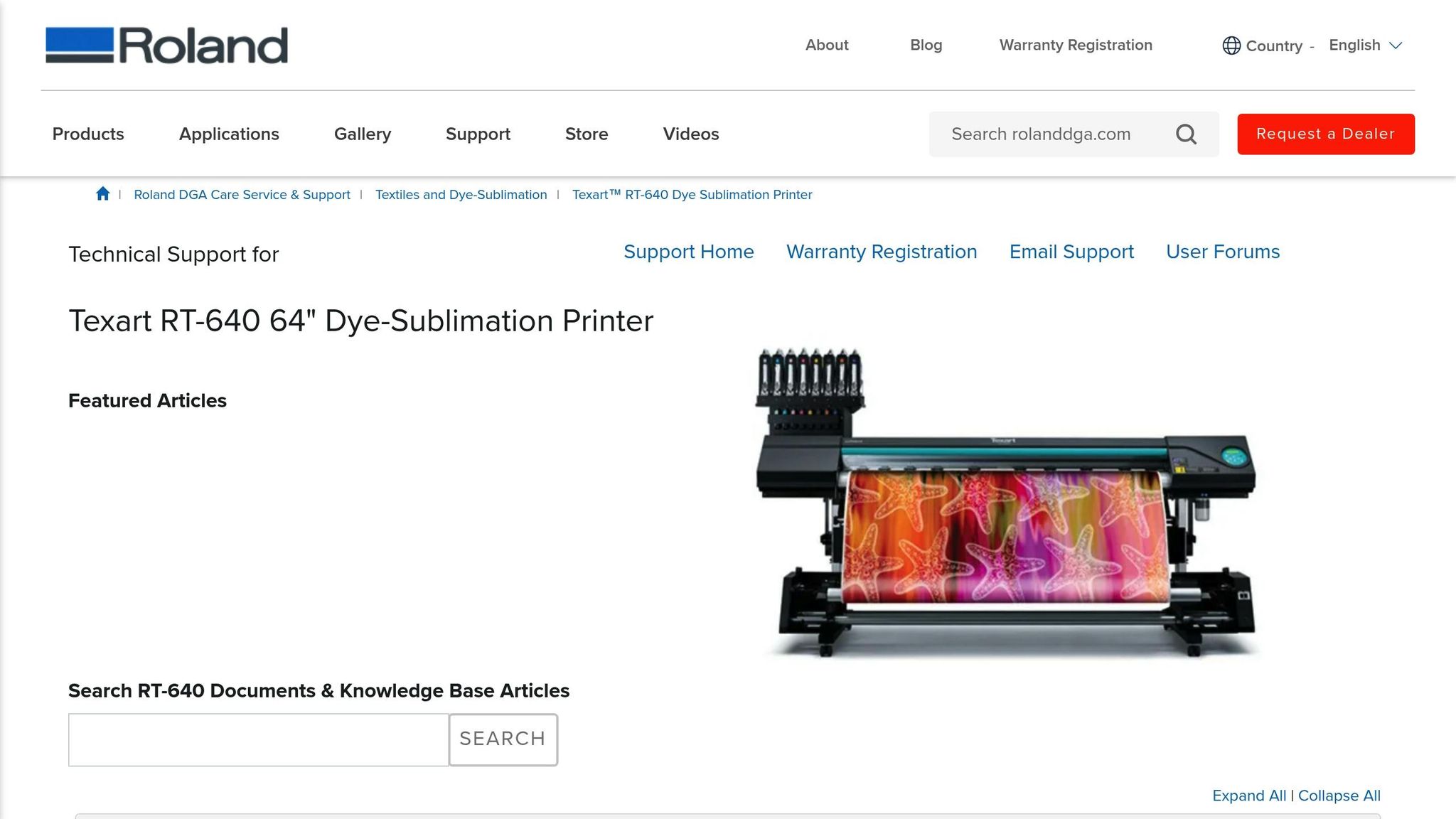

- Roland Texart RT-640: Mid-tier printer with remote monitoring, reliable speed, and flexible fabric compatibility.

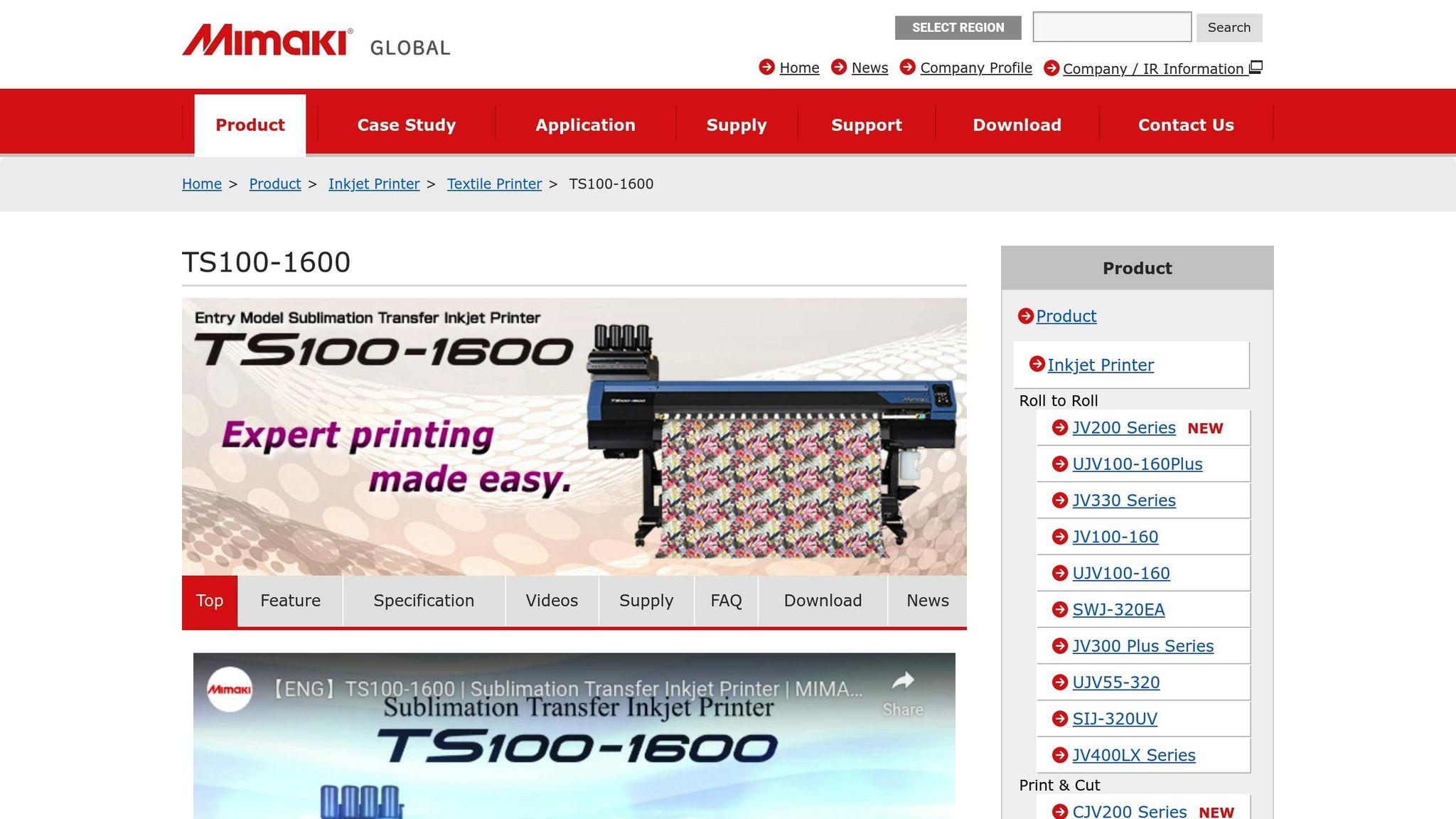

- Mimaki TS100-1600: Industrial-grade printer with smart maintenance and high-volume capabilities.

- Smart Heat Presses: Automated pressure and temperature control for consistent, professional-grade transfers.

Each option caters to different production scales, from small businesses to industrial operations. Sublimation printing is cost-effective, long-lasting, and ideal for polyester sportswear. Below is a quick comparison of these tools to help you decide.

Mimaki TS330-1600 Sublimation transfer inkjet printer

Quick Comparison

| Equipment | Key Features | Print Speed | Print Quality | Production Scale | Price Range |

|---|---|---|---|---|---|

| Epson SureColor F-Series | Cloud monitoring, high-speed, precise colors | Up to 1,590 ft²/hr | Vibrant, sharp colors | Small to large-scale | $499 – $32,995 |

| Sawgrass SG1000 | Compact, self-maintenance, ultra-fine resolution | Up to 156 prints/hr | High-definition | Small to medium-scale | ~$1,600 |

| Roland RT-640 | Remote monitoring, ink switching system | Up to 351 ft²/hr | Consistent quality | Medium to large-scale | $12,995 – $14,995 |

| Mimaki TS100-1600 | Predictive maintenance, fast output | Up to 753 ft²/hr | Industrial-grade | Large-scale | ~$10,995 |

| Smart Heat Presses | Automated pressure/temperature control | ~30 seconds per shirt | Durable, long-lasting | Small to medium-scale | Varies by model |

Choose equipment based on your production needs, budget, and desired output quality. Sublimation technology continues to grow, offering efficient solutions for personalized sportswear.

1. Epson SureColor F-Series

The Epson SureColor F-Series has become a key player in North America’s dye-sublimation printing industry, particularly for high-volume sportswear production. This printer line combines advanced automation with practical features tailored to meet the demands of uniform manufacturing.

Smart Automation Features

The SureColor F-Series is packed with automation tools that streamline the printing process. Features like auto-paper tension control ensure consistent fabric handling during long print runs, while fabric head wipers maintain print quality throughout continuous production cycles. Additionally, the Epson Cloud Solution PORT allows real-time monitoring and remote tracking of printer status. Select models also feature high-capacity ink tanks, enabling extended print runs without interruptions – perfect for large team orders where downtime for ink refills is not an option.

These automated systems are designed to deliver the speed and precision needed for modern sportswear production.

Print Quality and Speed for Sportswear Fabrics

Models such as the SureColor F9570 and F9570H offer impressive print speeds of up to 1,590 ft²/hr, while other models in the series achieve speeds of 1,169 ft²/hr. Using UltraChrome DS ink technology, these printers produce vibrant colors and sharp contrasts, ideal for sportswear fabrics. The PrecisionCore Micro TFP printheads, equipped with Nozzle Verification Technology, ensure consistent quality even at maximum speeds.

"These new SureColor F-Series printers deliver high-speed production without sacrificing high-quality results, allowing businesses to boost performance", says Lily Hunter, product manager at Professional Imaging, Epson America, Inc.

This combination of speed and quality ensures that even the most intricate designs are reproduced with precision.

Compatibility with Design Software and Platforms

The SureColor F-Series is built to work seamlessly with Adobe RGB workflows, ICC profiles, and Epson’s proprietary software, offering robust color management. Additionally, the Epson Garment Creator 2 software supports both direct-to-garment (DTG) and direct-to-film (DTFilm) job creation, providing flexibility for various sportswear applications.

A real-world example of its impact comes from Crystal’s Kre*ations. Owner Steven Salazar shared how the SureColor F1070’s user-friendly features and minimal maintenance needs significantly improved their business operations.

Scalability for Small to Industrial Production

The F-Series caters to a wide range of production needs, from the entry-level SureColor F170 priced at $499 to industrial-scale models like the F9570 ($27,995) and F9570H ($32,995). The higher-end models are equipped with a Replaceable Ink Pack System that holds up to 20 liters of ink per color, making them ideal for large-scale uniform contracts.

"Print service providers are looking for versatile and productive dye-sublimation printers that will deliver quality work for their clients and help them gain a competitive edge", notes Lily Hunter from Epson America.

With options suited for both small businesses and large-scale operations, the SureColor F-Series offers the flexibility and performance needed to meet diverse production demands.

2. Sawgrass Virtuoso SG1000

The Sawgrass Virtuoso SG1000 is a compact sublimation printer designed for creating custom sports uniforms. It combines professional-quality results with the convenience small businesses and growing operations need to produce standout team apparel.

Smart Automation Features

The SG1000 simplifies the printing process with several automation features that minimize manual effort. It includes a self-maintenance mode to keep the printer running smoothly and an auto-clean function that activates every 10 hours to maintain consistent print quality. With built-in Wi-Fi, you can print wirelessly [23,26], while the Sawgrass Print Manager software offers centralized control for managing print jobs and colors. To ensure continuous auto-cleaning, keep the printer powered on. These features work together to deliver reliable, high-resolution prints with minimal hassle.

Print Quality and Speed for Sportswear Fabrics

This printer is specifically designed for polyester-rich fabrics (at least 75% polyester). It delivers sharp, high-resolution prints of up to 1,200 x 1,200 dpi, and for intricate designs, its Ultra Fine Photo Mode can achieve resolutions as high as 4,800 x 1,200 dpi [27,28].

Here’s a breakdown of its production speeds based on print mode:

| Print Mode | Resolution | Speed |

|---|---|---|

| High Speed | 600 x 600 dpi | 15 seconds |

| High Quality | 600 x 600 dpi | 29 seconds |

| Advanced Photo | 1200 x 600 dpi | 48 seconds |

| Ultra Fine Photo | 4800 x 1200 dpi | 6 minutes 40 seconds |

Under ideal conditions, the SG1000 can produce up to 156 prints per hour. The sublimated designs are long-lasting and resistant to fading, even after multiple washes, making this printer a great choice for durable sportswear.

Compatibility with Design Software and Platforms

The SG1000 integrates effortlessly with popular design tools, including CorelDraw (X6 or later), Adobe Illustrator, Adobe Photoshop (CS6 or Creative Cloud), and Adobe Photoshop Elements (12 or later). Users can also access MySawgrass, a platform that combines design, printing, and sales tools in one place. MySawgrass features an easy-to-use interface and advanced editing capabilities, allowing creators to design and sell their products without upfront fees. Additionally, the Sawgrass Print Utility ensures optimal color accuracy, and Sawgrass Academy offers online training to help users get the most out of their printer.

Scalability for Small to Industrial Production

For businesses looking to expand, the SG1000 offers practical scalability. It’s backward-compatible with SG800 accessories, which means you can upgrade without losing prior investments [25,26]. Its reliable automation, consistent output quality, and seamless software integration make it an excellent choice for scaling up sportswear production.

3. Roland Texart RT-640

The Roland Texart RT-640 is a mid-tier sublimation printer designed to deliver reliable automation and efficiency for sportswear production. Its standout feature is an ink switching system that supports unattended printing and remote monitoring, making it a dependable choice for businesses focused on consistent output.

Advanced Automation for Streamlined Printing

The RT-640 comes equipped with the Roland Ink Switching System, which holds up to 2,000 ml of ink per CMYK color. This setup allows for uninterrupted printing sessions without constant supervision. Notifications via Roland OnSupport – sent through text or email – keep you updated, while the Printer Assist iPad app lets you manage operations remotely. To ensure smooth, high-speed printing, a built-in feed adjuster automatically compensates for media variations, maintaining stability throughout the process. These automation features help make production both efficient and reliable.

Exceptional Performance on Sportswear Fabrics

Tailored for polyester sportswear, the RT-640 produces vibrant colors and delivers stable results. It achieves printing speeds of up to 351 ft²/hr (32.6 m²/hr), making it suitable for medium to high-volume production.

"The Texart delivers the speed and power of textiles right down to the finest detail." – Roland DGA

For added flexibility, the RT-640M model supports both direct-to-fabric printing and paper transfer methods. This versatility allows you to work with a wide range of sportswear materials while maintaining precise alignment for large-format prints.

Seamless Integration with Design Software

To complement its automation, the RT-640 integrates smoothly with advanced RIP software. It comes bundled with ErgoSoft Roland Edition 2, which includes tools specifically designed for textile dye-sublimation and supports up to eight simultaneous jobs. Additionally, it’s compatible with VersaWorks 7 RIP software, which processes designs up to 3.9 times faster than earlier versions and uses 62% more memory for handling intricate details. VersaWorks 7 works on both Windows and macOS, offering detailed color matching to ensure accurate reproduction of logos and designs. Roland also provides a Fluorescent Color Library for Adobe Illustrator and Corel, expanding design possibilities.

Scalable for Growing Businesses

Priced between $12,995 and $14,995, the RT-640 offers an accessible upgrade for businesses transitioning from desktop printers to larger-scale production. Its high ink capacity and automation features make it ideal for scaling operations, from custom orders to bulk team uniform contracts.

"The RT-640M is an unbeatable investment for anyone looking to get into the dye-sublimation market… Its multi-function capabilities allow users to easily and cost-effectively produce everything from flags, soft signage and backlit signage to ChromaLuxe photo panels, apparel, and décor."

– Lily Hunter, Roland DGA Product Manager, Textiles and Consumable Supplies

With the ability to handle both direct-to-textile and indirect sublimation printing, the RT-640 adapts to changing production demands, making it a versatile tool for growing sportswear businesses.

sbb-itb-4d95ad3

4. Mimaki TS100-1600

The Mimaki TS100-1600 is a sublimation printer built for industrial use, offering smart automation to streamline high-volume sportswear production. Whether you’re handling small custom orders or large-scale team uniform contracts, this printer is designed to meet the demands of modern sportswear businesses.

Smart Automation Features

The TS100-1600 is packed with intelligent systems that reduce manual intervention and keep production running smoothly. One standout feature is the Dynamic Adjustment System (DAS), which automatically calibrates dot positioning and media feeding. This ensures consistent print quality, even during long production runs – an essential factor when creating large batches of uniforms where color consistency matters most.

Additionally, the Nozzle Check Unit (NCU) and Nozzle Recovery System (NRS) work together to monitor print head performance and resolve minor clogs before they impact output. These features minimize downtime and help meet tight deadlines, making the TS100-1600 a reliable choice for sports team orders.

"With an increase in demand for personalisation, bespoke prints and custom decor, the new TS100-1600 offers companies a low-cost route into this proven technology."

– Brett Newman, Managing Director at Hybrid Services

These automation tools are the backbone of the TS100-1600, enabling exceptional speed and print quality without constant oversight.

Print Quality and Speed for Sportswear Fabrics

Optimized for polyester sublimation, the TS100-1600 produces vibrant, detailed graphics tailored for sportswear. With dual staggered print heads, it achieves speeds of up to 753 square feet per hour (70 m²/h), making it nearly twice as fast as the older JV150-160 model in its highest-speed mode .

The printer supports resolutions up to 1,200 dpi, ensuring crisp logos and intricate designs, while Mimaki’s MAPS4 technology stabilizes color reproduction across various fabric types . It also uses Sb610 sublimation ink, specially formulated for textiles, to maintain consistent quality throughout production.

Compatibility with Design Software and Platforms

The TS100-1600 doesn’t just excel mechanically – it also integrates seamlessly with design workflows. It comes with RasterLink7 RIP software, which processes designs 25% faster than its predecessor. This improvement is particularly useful for handling complex uniform designs with gradients and multiple colors.

Additionally, the printer’s 1,600 mm print width allows for efficient use of wide-format materials, and the Dot Adjustment System ensures consistent results across runs. These features make it a practical choice for businesses producing intricate and large-scale designs.

Scalability for Small to Industrial Production

At a price point of $10,995, the TS100-1600 offers flexibility for both small-scale and industrial-level production. From creating samples to fulfilling high-volume contracts, it handles a wide range of sportswear applications, including leggings, jerseys, swimsuits, and activewear. Its ability to maintain consistent quality across different jobs makes it a strong investment for businesses looking to grow in the sportswear market .

5. Smart Heat Presses

In the sublimation process, heat presses are the final and critical step that transforms high-quality prints into durable, professional-grade sportswear. Smart heat presses have taken this process to a new level, offering precision and consistency that make them indispensable for creating custom team uniforms. These advanced machines simplify the transfer process, ensuring reliable results without the guesswork.

Smart Automation Features

The HTVRONT Auto Heat Press is a great example of this technology. It heats up to 320°F (160°C) in just 4 minutes and automatically adjusts pressure based on the thickness of the material. Its auto-release feature ensures designs are applied evenly and prevents scorching, making it adaptable for different fabric types.

The xTool Heat Press goes a step further by maintaining temperature accuracy within ±5°F and heating up 30% faster than traditional models. With digital touch screens, IoT updates, and auto open/lock functions, these presses streamline the transfer process for efficiency and ease of use.

Secabo’s TC SMART series adds a unique touch with its Bluetooth-enabled interface. It connects to the Secabo SMART Transfer app, which provides a database of transfer settings and step-by-step instructions for multi-stage transfers. This feature allows operators to quickly access the best settings for various fabric and transfer material combinations right from their smartphones.

Together, these features make smart heat presses a game-changer for achieving precise and efficient transfers on sportswear fabrics.

Print Quality and Speed for Sportswear Fabrics

Smart heat presses are designed to deliver outstanding transfer quality and speed. They excel in applications like Direct-to-Film (DTF) printing, where maintaining precise pressure and temperature is vital for transferring designs onto sportswear fabrics. Thanks to electronic controls, these machines ensure consistent results across production runs.

Speed is another highlight. With optimized workflows, a single shirt can be pressed in as little as 4 seconds, with the entire cycle (loading and unloading included) taking just 30 seconds. This means operators can process around 50 shirts in about 25 minutes.

Ninja Mike, Founder and CEO of Ninja Transfers, emphasizes the importance of quality over speed:

"This is a mistake because performing a second press increases durability, reduces shine, and further integrates the print into the garment, greatly improving the hand feel. Pressing twice results in quality, which is more important than speed because it’s how you win the customer for the long term."

The quality of the heat press directly affects the durability and feel of the print on sportswear. Techniques like a controlled second press can significantly enhance the integration of the design into athletic fabrics.

Scalability for Small to Industrial Production

Smart heat presses are versatile, catering to both small custom orders and large-scale production. The HTVRONT Auto Heat Press, for instance, has earned a 4.6-star rating on Amazon from over 5,400 reviews. Users frequently praise its consistent performance on materials like cotton, polyester, and sublimation substrates.

One satisfied customer, Grind & Glo, shared:

"The HTVRONT Auto Heat Press has completely changed how I do shirts, tote bags, and sublimation projects. No more playing arm-wrestling with clunky manual presses – just load it, push a button, and boom, she seals the deal."

For businesses evaluating their options, here’s a quick comparison between manual and automatic heat presses:

| Aspect | Manual Heat Press | Automatic Heat Press |

|---|---|---|

| Operation Mechanism | Hand-operated lever; requires physical effort | Electric motor with automated controls |

| Physical Effort | High; leads to fatigue during extended use | Low; ideal for high-volume production |

| Precision & Consistency | Relies on operator skill; variability possible | High accuracy and repeatability; programmable |

| Workflow Efficiency | Suitable for small-scale or occasional use | Speeds up production with autonomous operation |

Equipment Comparison Table

The table below summarizes the main features of various smart sublimation equipment tailored for sportswear production. It provides a snapshot of their capabilities, helping manufacturers determine the best fit for their needs.

| Equipment | Smart Features | Print Speed | Print Quality | Fabric Compatibility | Software Integration | Production Scale |

|---|---|---|---|---|---|---|

| Epson SureColor F-Series | Advanced print tech with automated maintenance | High throughput for varied needs | Professional-grade, vibrant color output | Optimized for polyester and poly-blend fabrics | Works with dedicated RIP and design software | Small to large-scale production |

| Sawgrass Virtuoso SG1000 | Sublimation ink tech with automated color management | Efficient for small to medium runs | Ultra-high definition with accurate colors | Ideal for polyester and coated substrates | Integrated with Sawgrass Creative Studio | Small to medium production |

| Roland Texart RT-640 | Intelligent controls with remote monitoring | Robust speed for medium to large runs | High-res prints with consistent color density | Supports various polyester textiles and transfer media | Compatible with dedicated RIP software | Medium to large-scale production |

| Mimaki TS100-1600 | Smart maintenance with predictive alerts | Designed for industrial-scale output | Industrial-grade quality and durability | Optimized for a wide range of polyester fabrics | Advanced RIP and cloud-based management tools | Large-scale, industrial production |

| Smart Heat Presses | Auto-adjustment and wireless connectivity | Efficient for rapid small batches | Consistent, high-quality transfers | Works with various sublimation-suitable fabrics | Mobile integration for streamlined operation | Small to medium production |

Key Takeaways

Dye sublimation technology is a standout choice for sportswear production, offering vivid, long-lasting prints that are perfect for athletic apparel. Its compatibility with polyester and polyester-blend fabrics makes it ideal for creating lightweight, breathable garments.

Each system’s software integration can significantly impact workflow efficiency. Some equipment includes tools like template libraries and dedicated design software that simplify the sublimation process. For smaller orders, entry-level smart heat presses are a practical choice. On the other hand, systems like the Mimaki TS100-1600 cater to high-volume, industrial-scale production.

Another advantage of sublimation printing is its cost-effectiveness for customization. Unlike traditional methods, it eliminates additional setup expenses, making intricate, multi-color designs more affordable. Choosing the right equipment depends on balancing current production demands with future growth, ensuring manufacturers invest wisely without overspending on unnecessary capacity.

Conclusion

The rise of smart sublimation equipment has reshaped the sportswear industry by offering exceptional quality, faster production times, and greater customization options. The global sublimation market, valued between $3 and $5 billion annually, reflects the increasing demand for personalized, high-quality athletic apparel. These advancements not only improve production efficiency but also set the stage for continued growth in the industry.

The equipment highlighted in this discussion showcases how automation and advanced software are revolutionizing traditional printing processes. By reducing downtime and ensuring consistent output, these tools are proving indispensable. Sublimation printing also stands out for its cost-effectiveness, especially in on-demand production environments. With 30% of custom team uniforms now created using sublimation methods, the technology’s impact on sports apparel is undeniable.

When investing in sublimation equipment, it’s essential to prioritize fabrics with a high polyester content to achieve vibrant, accurate colors. Additionally, using design software that supports CMYK color mode helps ensure precise color adjustments.

Emerging trends like smart textiles and 3D sublimation further highlight the advantages of advanced sublimation technology. As the digital printing market is projected to reach $40.8 billion by 2028, businesses adopting smart sublimation tools now will be better equipped to seize future opportunities.

To stay competitive, focus on equipment that delivers a balance of print quality, speed, user-friendliness, and cost efficiency. By aligning your choice with your business’s unique needs, you can strengthen your production capabilities and secure a stronger position in the custom sportswear market.

FAQs

What should I consider when selecting sublimation equipment for sportswear production at different scales?

When choosing sublimation equipment for sportswear production, it’s crucial to align your selection with the size of your operation and the features needed to achieve your production targets.

For small-scale production, compact printers are a smart choice. They’re straightforward to set up, deliver excellent color precision, and produce sharp, high-resolution prints – perfect for crafting custom designs in smaller batches. On the other hand, large-scale production calls for high-capacity printers. Look for models with faster speeds, reliable ink systems, and consistent performance to manage higher output efficiently.

No matter the scale, focus on durability and cost-effectiveness. Reliable equipment ensures vibrant, long-lasting prints that elevate the appearance and functionality of sports uniforms. At the same time, cost-efficient options help you stay profitable without sacrificing quality.

How do smart features and automation in sublimation equipment improve efficiency and print quality?

Smart Features and Automation in Sublimation Equipment

Modern sublimation equipment is taking efficiency to the next level with smart features and automation. These advancements help speed up production, cut down on downtime, and deliver consistent results with minimal effort.

Thanks to advanced sensors, automated adjustments ensure precise settings are maintained. This reduces the chances of errors and limits the need for manual tweaks. Key parameters like temperature, pressure, and ink distribution are fine-tuned in real-time, ensuring every print comes out vibrant and high-quality. The result? A streamlined process that saves time while producing professional-grade custom sportswear.

Why is polyester the top choice for sublimation printing on sportswear, and how does it impact the quality of the design?

Polyester stands out as the top choice for sublimation printing because it lets the dye bond directly with its fibers during the heat transfer process. This results in bright, durable designs that resist cracking, peeling, or fading, even with regular use. The prints stay vibrant, making polyester a go-to fabric for long-lasting quality.

Beyond its sublimation-friendly nature, polyester offers moisture-wicking, breathable, and wrinkle-resistant qualities, making it an excellent option for sportswear. These features not only boost comfort and performance for athletes but also keep uniforms looking sharp during intense activities. With its blend of toughness and practicality, polyester ensures custom sports uniforms leave a strong impression both on and off the field.